Smart integrated rod expansion groove anti-fall off components

A capacity expansion slot and anti-slip technology, which is applied in the direction of towers, building types, buildings, etc., can solve the problems of anti-loosening bolt components falling off, expansion equipment slipping, falling off, etc., to avoid sliding, solve the risk of slipping, and ensure the reliability of fixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

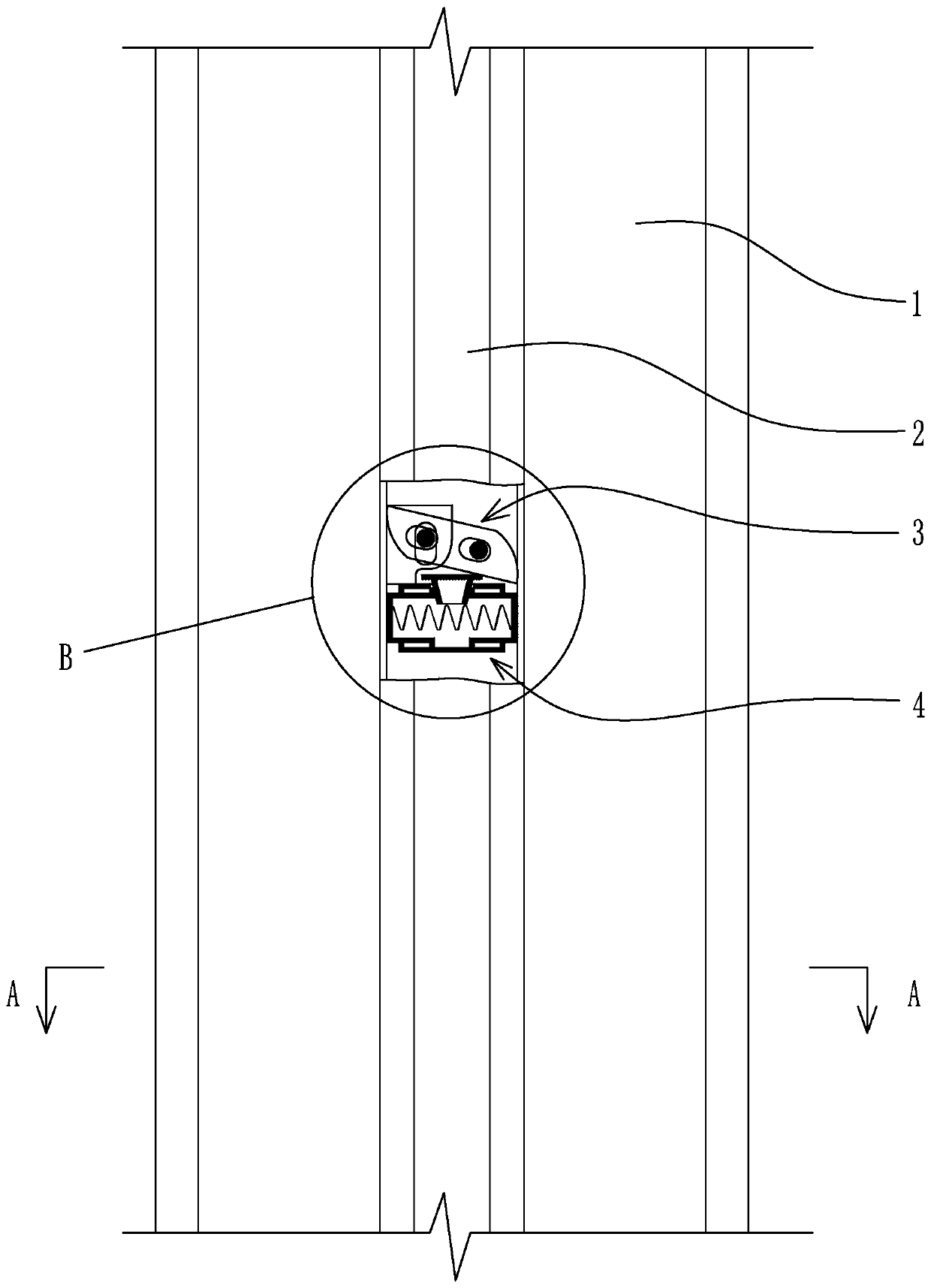

[0039] Embodiment one: if figure 1 As shown in the figure, an anti-slip component of a smart comprehensive pole expansion groove includes a vertical pole 1, an anti-slip bolt assembly 3 and a force-based anti-slip clip 4.

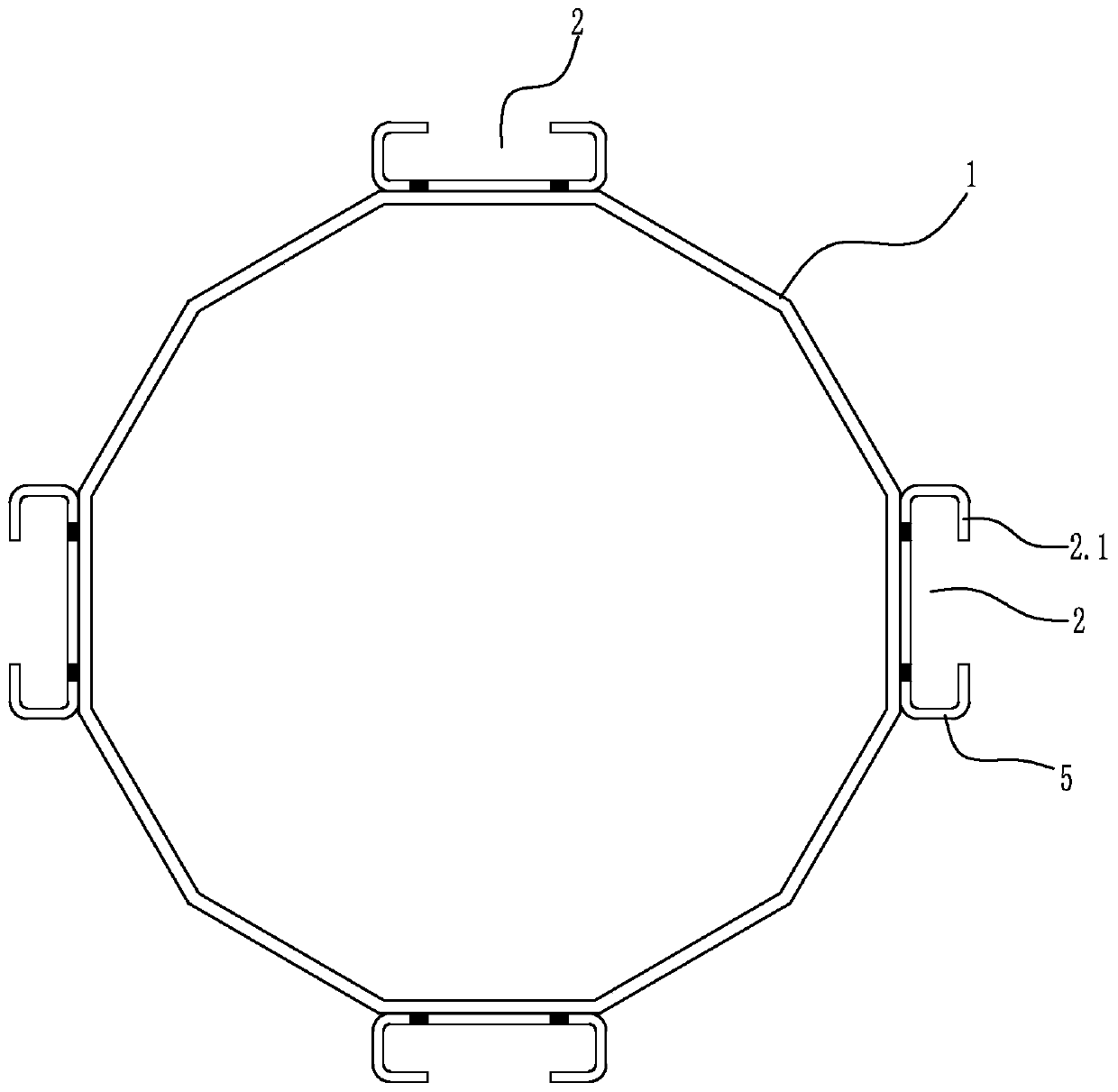

[0040] Such as figure 1 , figure 2 As shown, the outer surface of the pole 1 is provided with an expansion slot 2 extending up and down, and the notch of the expansion slot has two notch sides extending up and down. Formed notch baffle plate 2.1; in the present embodiment, the outer surface of the vertical rod is provided with C-shaped steel 5 extending up and down, and the C-shaped steel is connected to the vertical rod by welding, and the inner cavity of the C-shaped steel constitutes the expansion groove. The curling of the notch of the C-shaped steel constitutes the notch baffle.

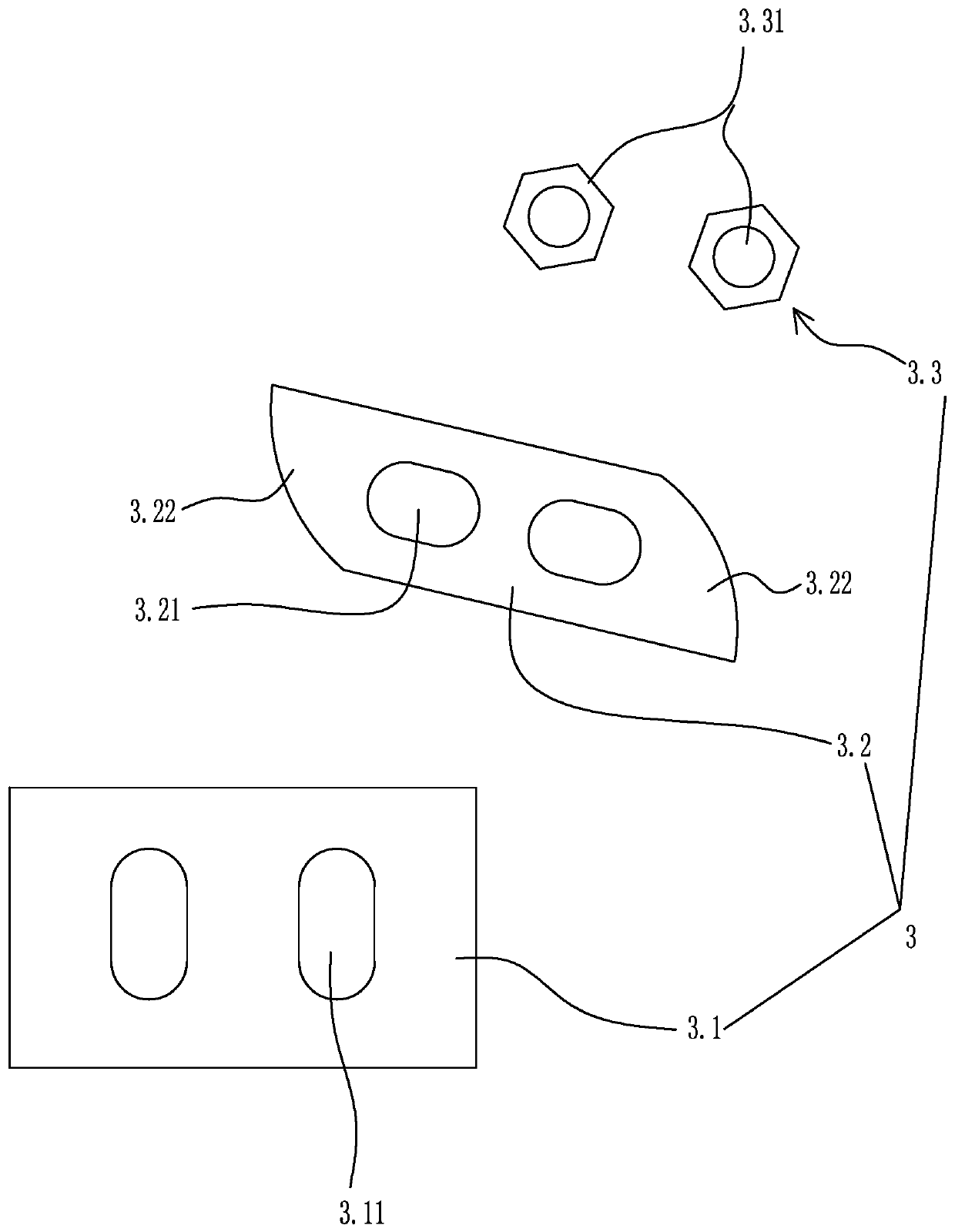

[0041] Such as image 3 , Figure 4 , Figure 5 As shown, the anti-off bolt assembly 3 includes an anti-off inner plate 3.2 located in the expansion slot, an anti-of...

Embodiment 2

[0054] Embodiment two: the remaining structure of this embodiment is with reference to embodiment one, and its difference is:

[0055] Such as Figure 8 As shown, the through hole of the inner plate is a round hole, and the connecting bolt 3.31 is connected to the anti-off inner plate 3.2 by welding. In this way, the connecting bolt and the anti-off inner plate are connected as a whole. , can avoid slipping between the connecting bolt and the anti-off inner plate, and is conducive to locking the anti-off inner plate and the anti-off outer plate on the notch baffle through the connecting bolt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com