Self-ejection type positioning pin for sliding plate

A technology for positioning pins and sliding plates, which is applied in threaded fasteners, connecting components, screws, etc., can solve the problems of time-consuming, labor-intensive, low-efficiency, and difficult to pull out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

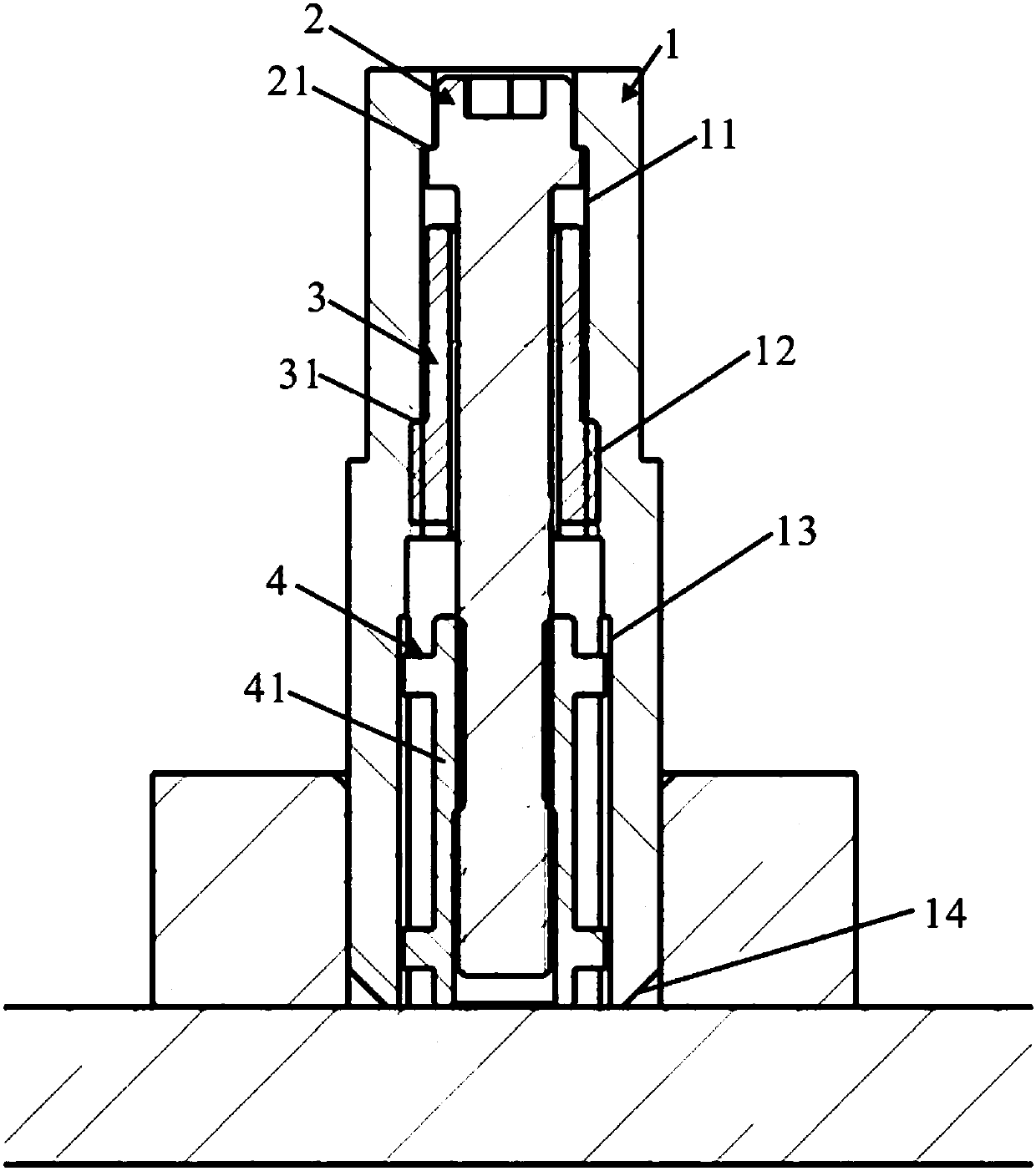

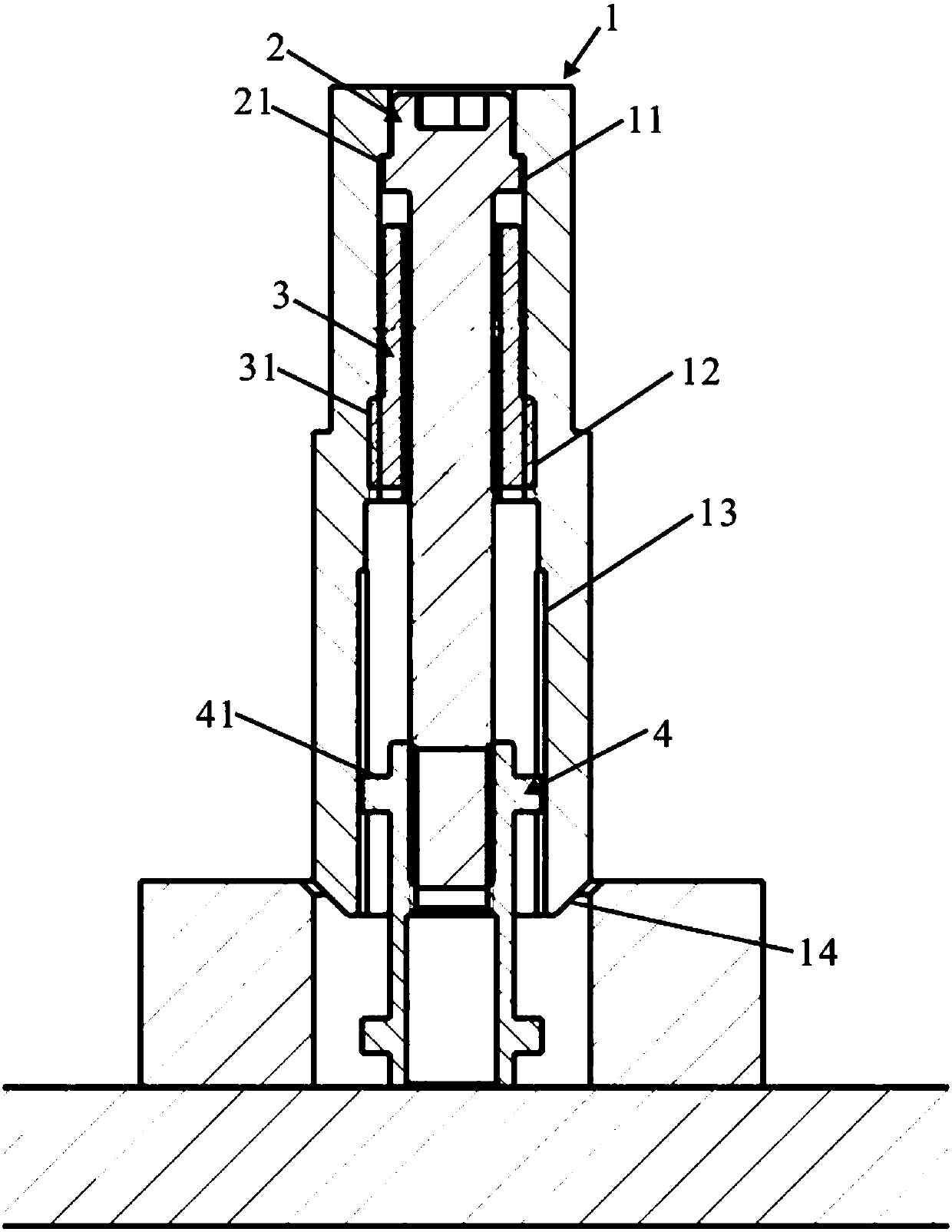

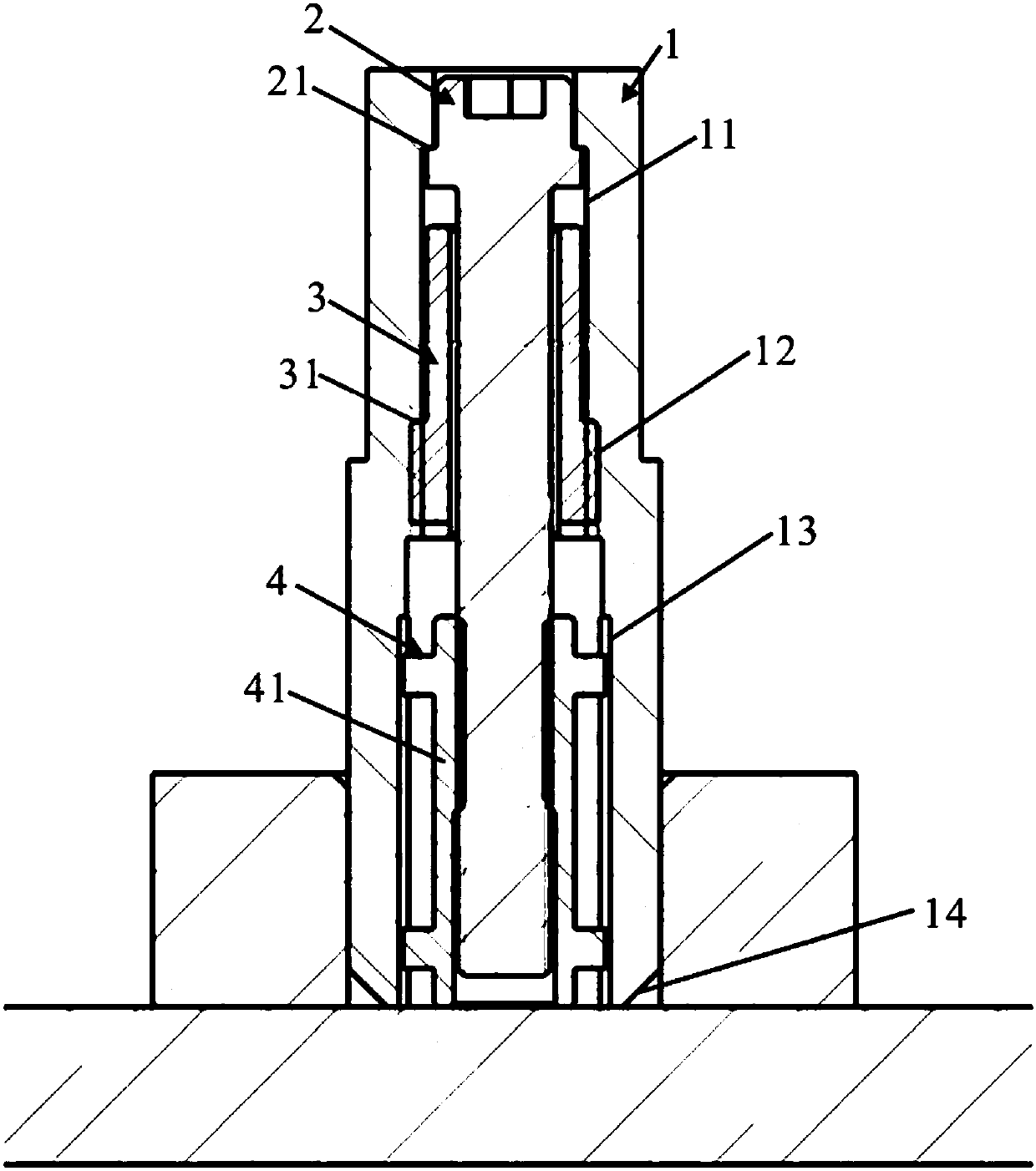

[0018] The following with attached Figure 1 to Figure 2 A sliding plate self-top positioning latch of the present invention will be further described in detail.

[0019] A sliding plate self-top positioning pin of the present invention, please refer to Figure 1 to Figure 2 Relevant figures include pin body 1, screw rod 2, limit sleeve 3 and top sleeve 4, the pin body 1 can be releasably plugged into the pin hole of the plug seat, and the screw rod 2 can be releasably plugged into the pin hole. In the pin body 1, the upper part of the screw rod 2 is in detachable abutment with the inner upper part of the pin body 1, and the inner wall of the limit sleeve 3 and the inner wall of the top sleeve 4 are threadedly connected to the outer wall of the screw rod 2, so that The limit sleeve 3 is located on the upper part of the top sleeve 4, the outer wall of the limit sleeve 3 is threadedly connected to the inner wall of the pin body 1, and the middle part of the limit sleeve 3 is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com