Aluminum alloy formwork system and its construction method

A technology of aluminum alloy formwork and construction method, which is applied to the preparation of formwork/formwork/work frame, formwork/formwork components, and building components on site, which can solve the problem of increasing construction time and cost and uneven stress on stair formwork , unstable positioning of stair formwork, etc., to save labor costs, facilitate skilled operation, and achieve good sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] An aluminum alloy formwork system, including multiple installation formworks and connectors, adjacent installation templates and opposite installation templates are connected by connectors, and 0.5-2cm of adhesive is applied to the connection between the connectors and the installation templates. The main component of the binder is clay. Adhesive is also applied to the joints of adjacent mounting templates.

[0050] The further installation formwork is covered with a 0.3-0.6 cm thick film on the concrete side. The film can be selected from polyethylene film, polypropylene film, polyvinyl chloride film or polyester film. The film extends from the ground along the installation direction of the installation template, the surface area of each film is greater than 4 times the surface area of each installation template, and the films attached to the opposite installation templates are arranged in parallel.

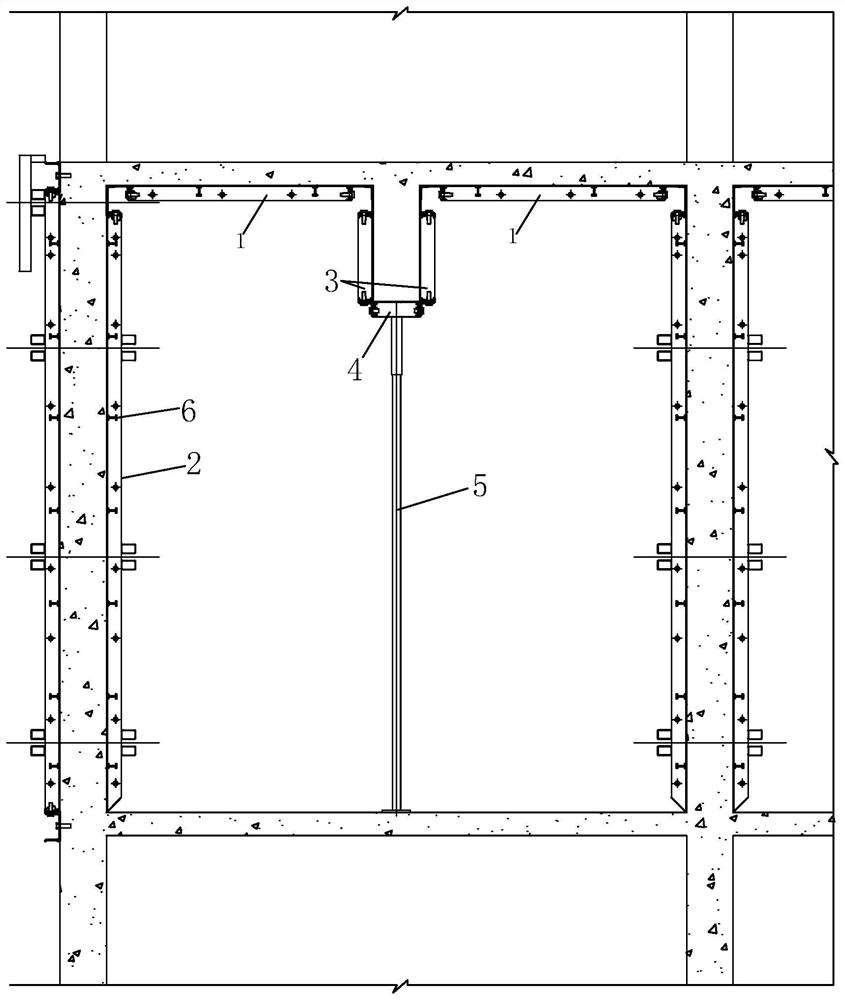

[0051] like figure 1 As shown, the installation template incl...

Embodiment 2

[0068] 1. Construction preparation

[0069] (1) Technical preparation

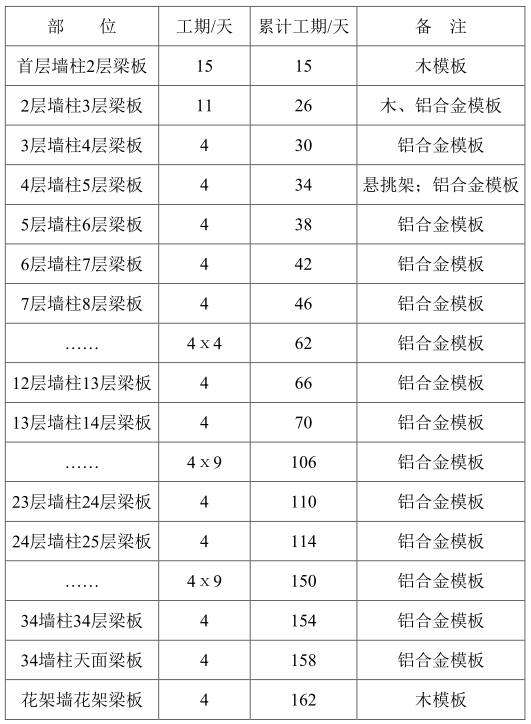

[0070] 1. According to the project structure form and contract duration requirements, design the construction site of the tower, write the operation process requirements and precautions.

[0071] 2. Template material preparation: prepare materials according to the template design drawing.

[0072] 3. According to the template design requirements, make safety and technical disclosure to the team.

[0073] 4. Measurement and setting out: after the concrete pouring of the floor is completed, the main control line is projected, all the column side lines are released on the floor, and the floor elevation line is measured on the diagonal line of the column reinforcement or on the steel pipe pole; before the formwork is installed , must review the elevation of the floor and the main control axis. The pole uses an adjustable pole, and the adjustment part is in the middle of the pole, which is easy to operate an...

Embodiment 3

[0178] The construction method of the aluminum alloy formwork system, the difference between embodiment 3 and embodiment 2 is that a number of ventilation pipes are inserted into the cavity formed by the installation formwork, and ventilation holes are evenly opened on the ventilation pipes. The ventilation pipe can be pre-buried on the ground in advance, and the ventilation holes are uniformly covered with the entire ventilation pipe, which is convenient for ventilation and is beneficial to increase the contact area between the concrete and the ventilation pipe; the material of the ventilation pipe is stainless steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com