A U-shaped steel bar hanger

A steel bar, U-shaped technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of low project quality, low lifting efficiency, poor safety, etc., to improve construction efficiency, simple and convenient operation and maintenance, prevent Falling off the hurting effect

Active Publication Date: 2022-05-31

HUAZHONG UNIV OF SCI & TECH +2

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Aiming at the above defects or improvement needs of the prior art, the present invention provides a U-shaped steel bar spreader, the purpose of which is to solve the problems of poor safety, low engineering quality and low lifting efficiency in the lifting process of U-shaped steel bars in the prior art. question

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0042] The lithium battery 47 is used as a power source in the drive assembly, and is fixed on the H-shaped steel secondary beam web 31 area near the center of the sling;

[0046] The retrofit pin 53 includes a retrofit pin shaft 534 and a plug guide ring 531, and the retrofit pin shaft 534 is attached to the main steel pipe 511

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

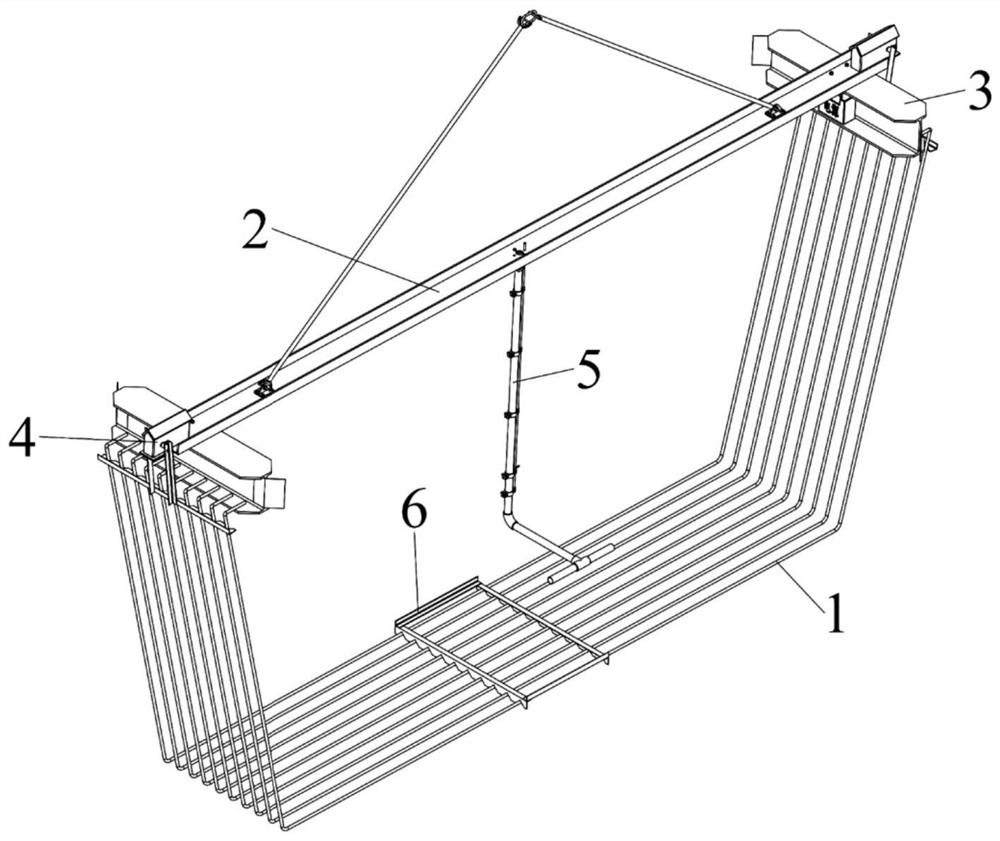

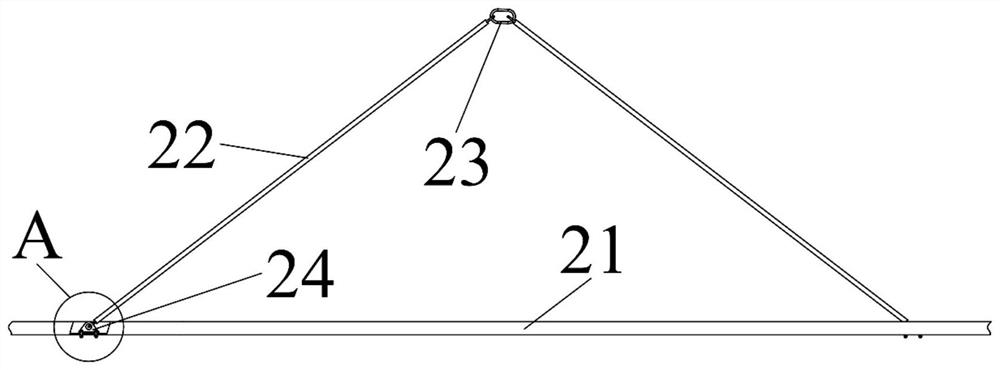

The invention belongs to the field of load hanging mechanical devices, and specifically discloses a U-shaped steel bar hanger, which includes a channel steel main beam, an H-shaped steel secondary beam, and an electric-driven slotted stop bar module, wherein: two H-shaped steel secondary beams respectively installed at both ends of the channel steel main beam, the top plate of the H-shaped steel secondary beam is fixed on the channel steel main beam, and the bottom plate is used to hook U-shaped steel bars; The beam is correspondingly arranged, which includes a driving assembly, a connecting rod and a blocking rod, the driving assembly is installed on the channel steel main beam, and is used to drive the connecting rod to rotate; the blocking rod is fixed at the lower end of the connecting rod, A row of equidistant V-shaped notches are provided on the retaining rod for snapping U-shaped steel bars. The U-shaped steel bar hanger of the invention is safe and reliable in operation, has high engineering quality, and can significantly improve hoisting efficiency.

Description

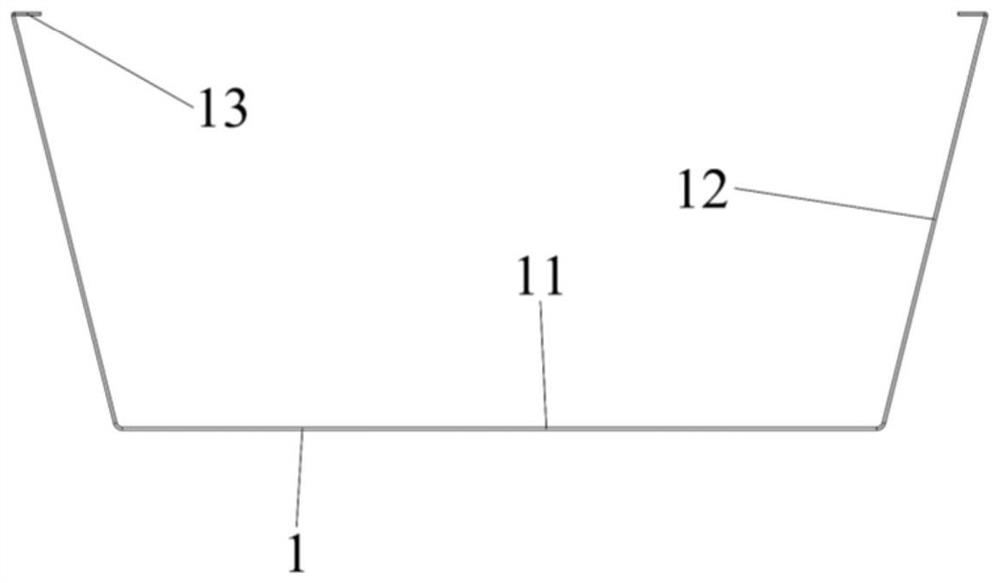

A U-shaped steel bar hanger technical field [0001] The invention belongs to the field of load-hanging mechanical devices, and more particularly, relates to a U-shaped steel bar spreader. Background technique In high-speed railway bridge construction, U-shaped steel bar is a kind of characteristic that the quantity used during the production of reinforced concrete box girder is more. The special shape ribbed steel bar, as shown in Figure 1, is characterized by the longest U-shaped steel bar bottom 11, the inclined U-shaped steel bar waist 12 and the The bottom is parallel to the shorter U-shaped steel bar ears 13. When making the steel frame of the box girder, it is necessary to transport the U-shaped steel bar to the steel frame to tie it. Puncture the tire and realize its accurate positioning and laying in the tire. Current technical scheme is: the first step, artificially several U-shaped steel bars stacked horizontally together use iron chain or The steel wire ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B66C1/10

CPCB66C1/10

Inventor 熊蔡华孙晨露梁杰俊一唐爱华程坤华张上伟李建军

Owner HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com