An improved solid combustion rate test device and test method

A solid combustion rate and testing device technology, applied in the field of chemical detection, can solve the problems of lack of protection circuit components, lack of intelligent measurement components, large test errors, etc., to achieve accurate determination of combustion distance and data collection, simple and convenient operation, temperature sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

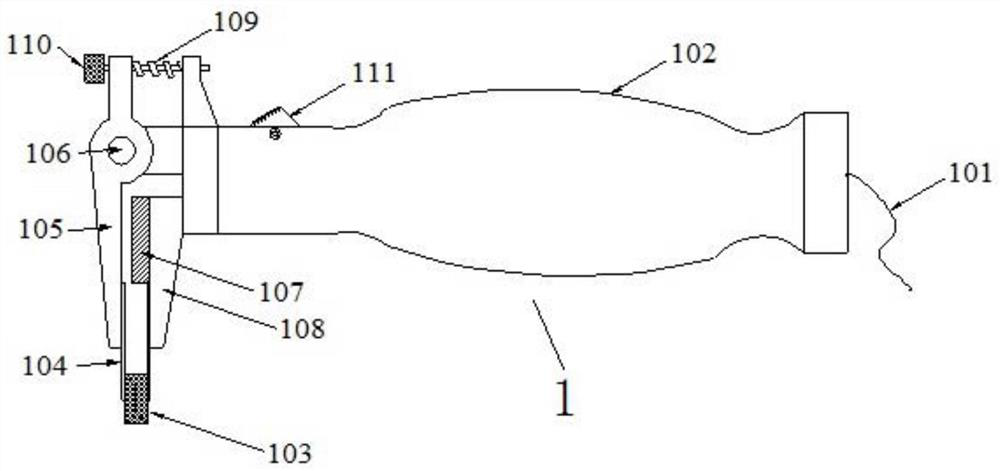

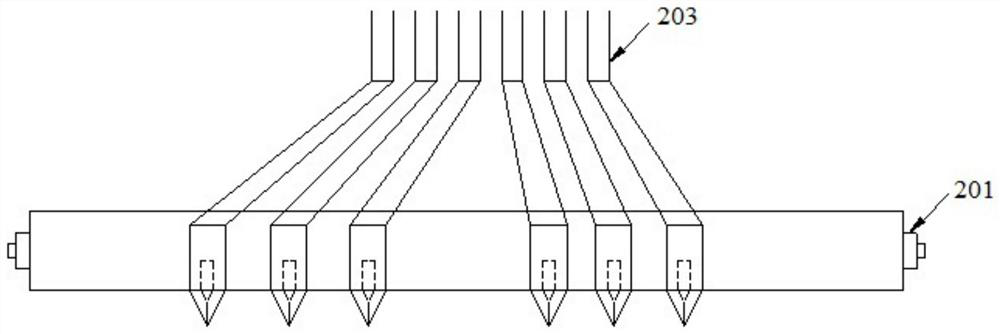

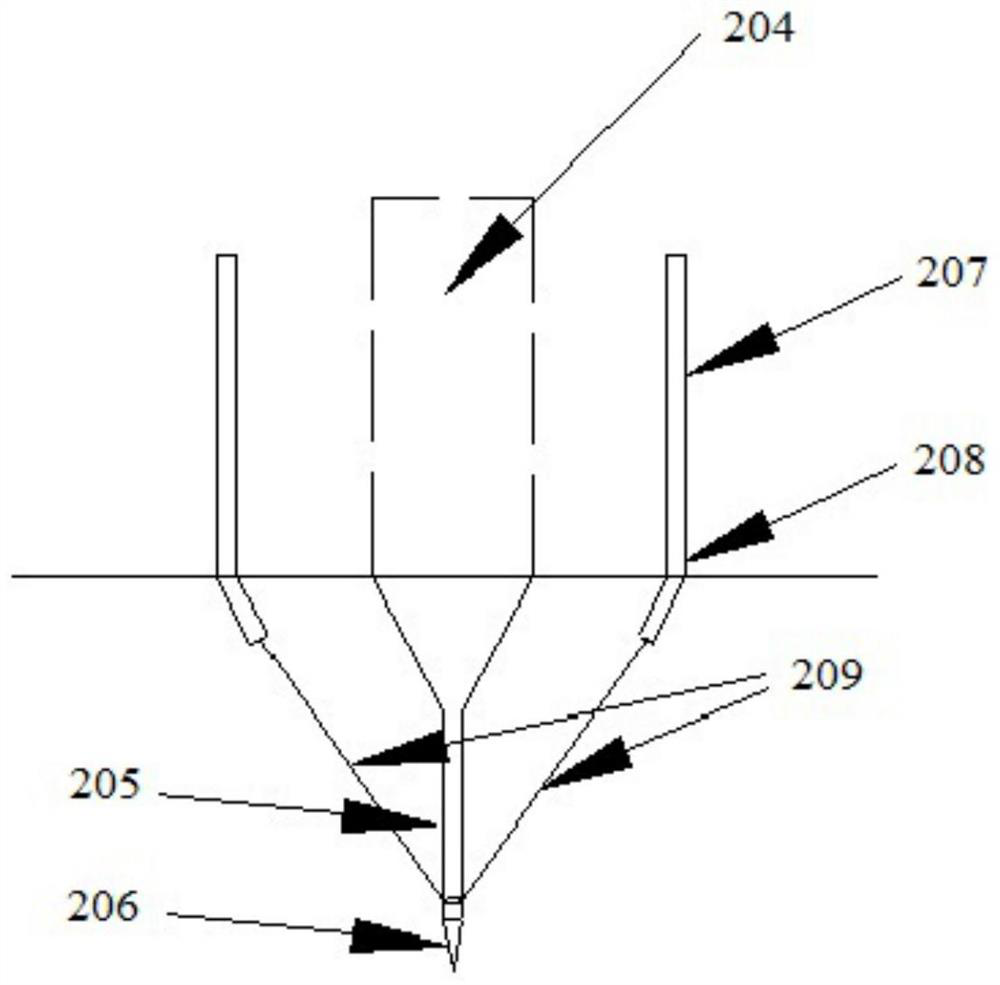

[0031] An improved solid combustion test device, which includes a heating element igniter for igniting the sample to be tested and a thermocouple array for monitoring the combustion of the sample to be tested, such as Figure 1-4 The heating element igniter is a clip-type exothermic element igniter, including a handle 102 and a heating unit located at one end of the handle 102. The heating unit includes a heating element 103, a high temperature resistant element 104 located on both sides of the heating element 103, and a The fixed electrode 108 and the movable electrode 105 outside the high temperature resistant element 104 are arranged on the handle 102 through the rotation of the first rotating shaft 106 , and the other end of the handle 102 is connected to the power controller 101 . The upper end of the movable electrode 105 is connected to a spring adjustment assembly, including a spring 109 and a clamping knob 110 , the handle 102 is provided with a switch 111 , and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com