Multi-grade accordion type honeycomb structure

A honeycomb structure, accordion technology, applied in the direction of sheet/board, building elements, etc., can solve the problems of resistance to local buckling deformation and low local collapse, and achieve the effect of optimized design and good bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

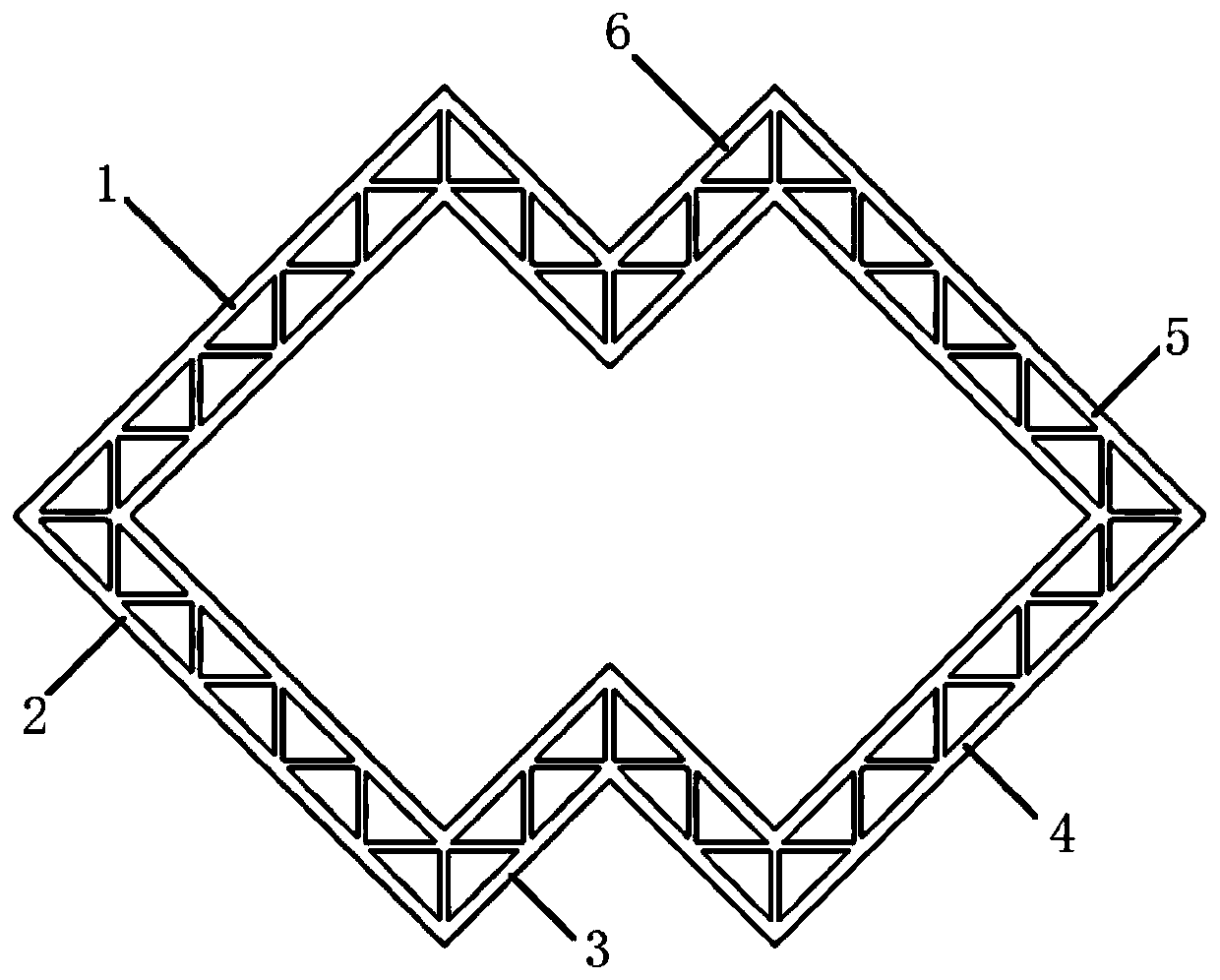

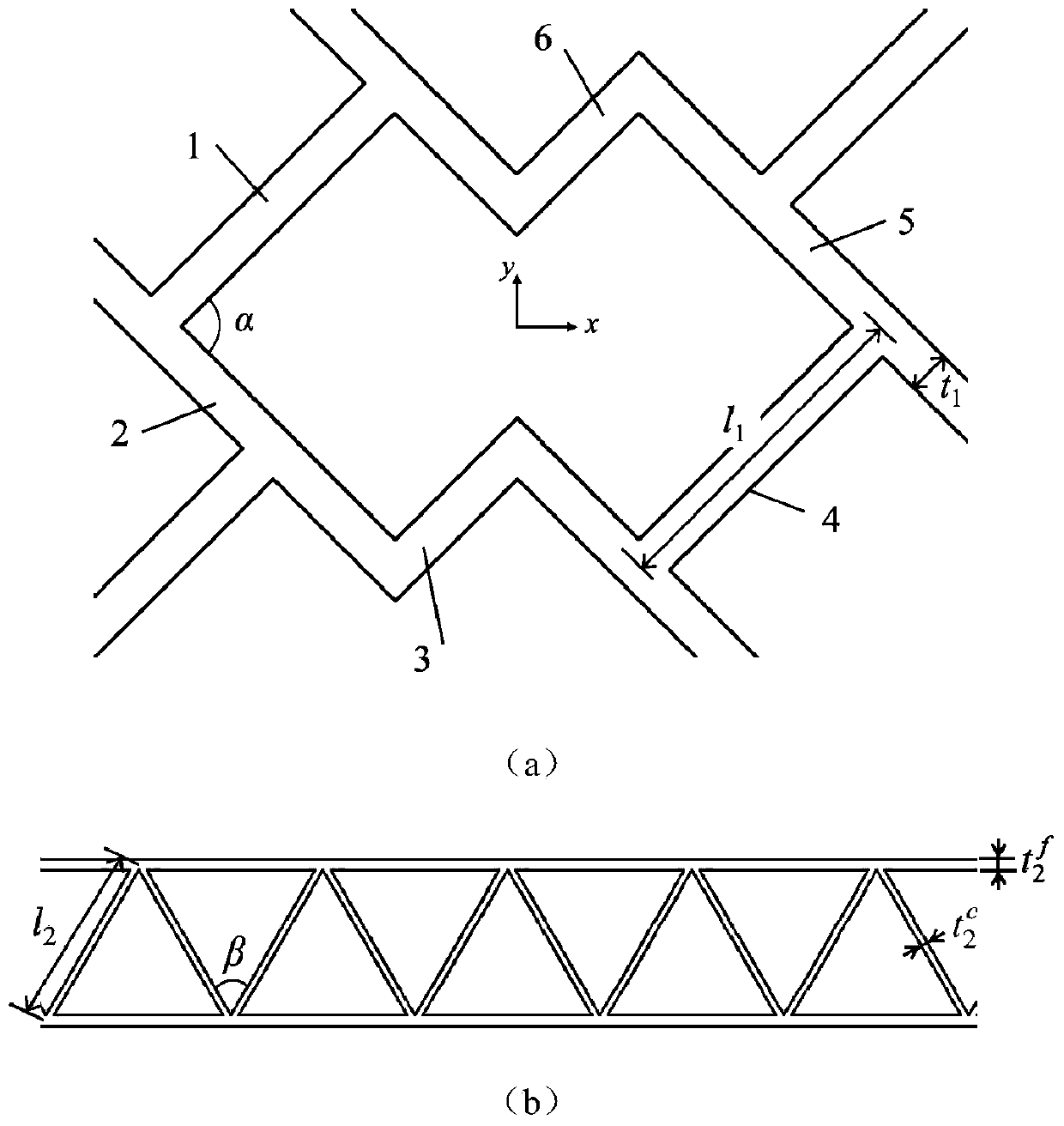

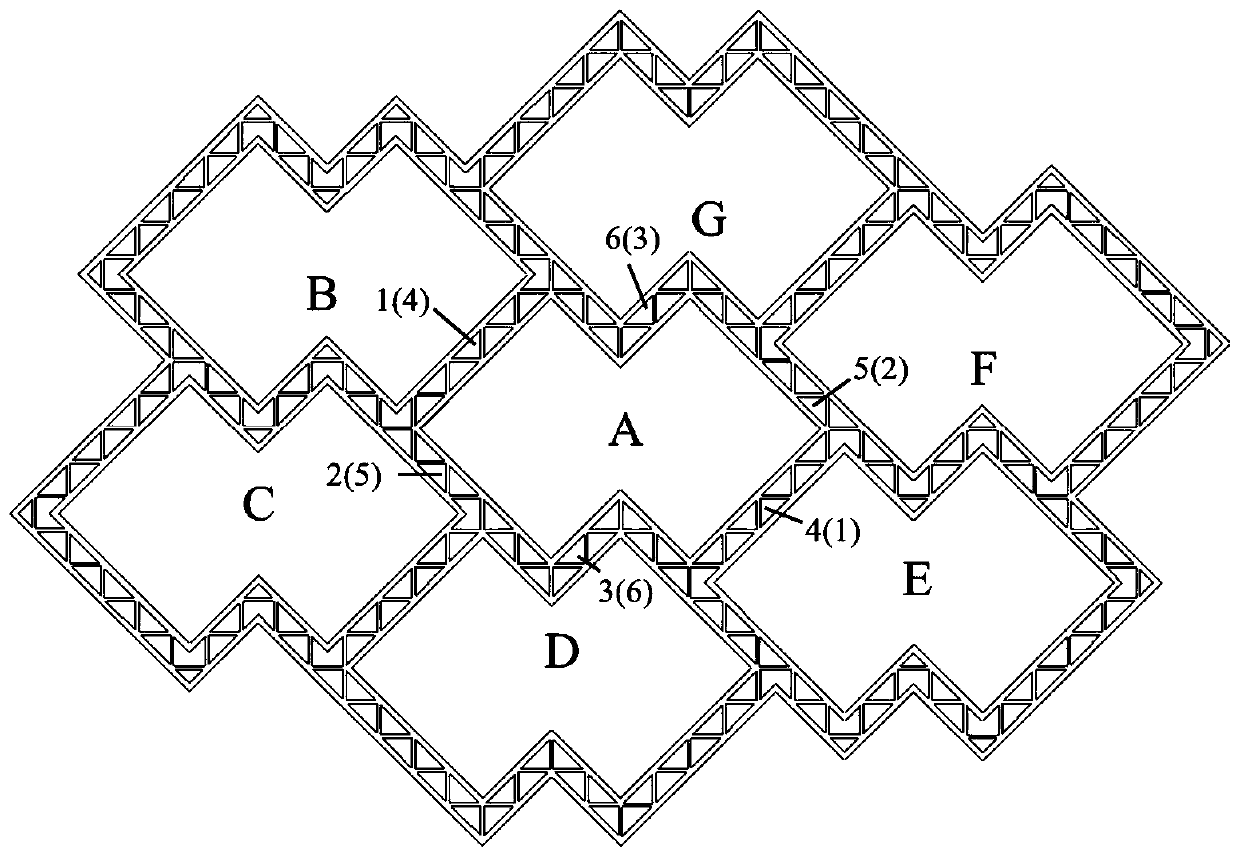

[0026] Such as figure 1 Shown, a kind of multistage accordion type honeycomb structure provided by the present invention, its representative cell is by figure 2 (a) The first-level accordion cell sum figure 2 (b) The two-stage corrugated board sandwich cells are compounded, and the corrugated sandwich board is replaced by the solid cell wall of the accordion honeycomb structure to obtain the multi-stage accordion-type honeycomb structure of the present invention. According to the relative relationship between the cells, the representative cell can be decomposed into three types of edges: the first full edge 1 and the second full edge 4, the first half edge 2 and the second half edge 5, and the first wave edge 3 and the second edge Wavy edges6. Wherein the first whole side 1 and the second whole side 4, the first half side 2 and the second half side 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com