Fireproof glass wall

A technology of fire-resistant glass and glass plate, which is applied in the direction of fire prevention and building components, etc. It can solve the problems of inconvenient installation of fire-proof glass and fire-proof rubber strips, unattractive appearance, poor mechanical properties, etc., and achieves simple structure, simple and convenient installation, and bearing good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

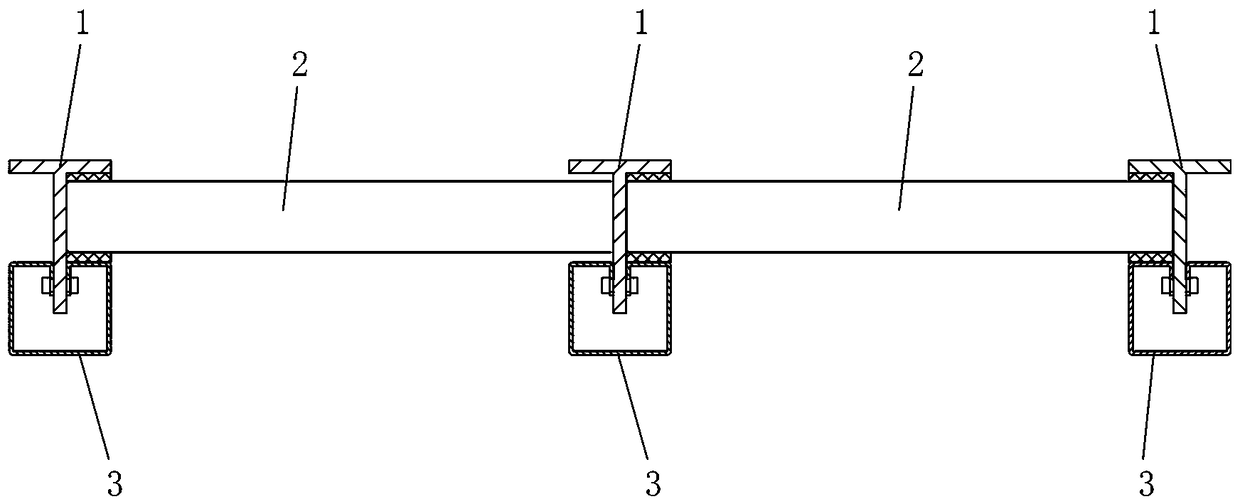

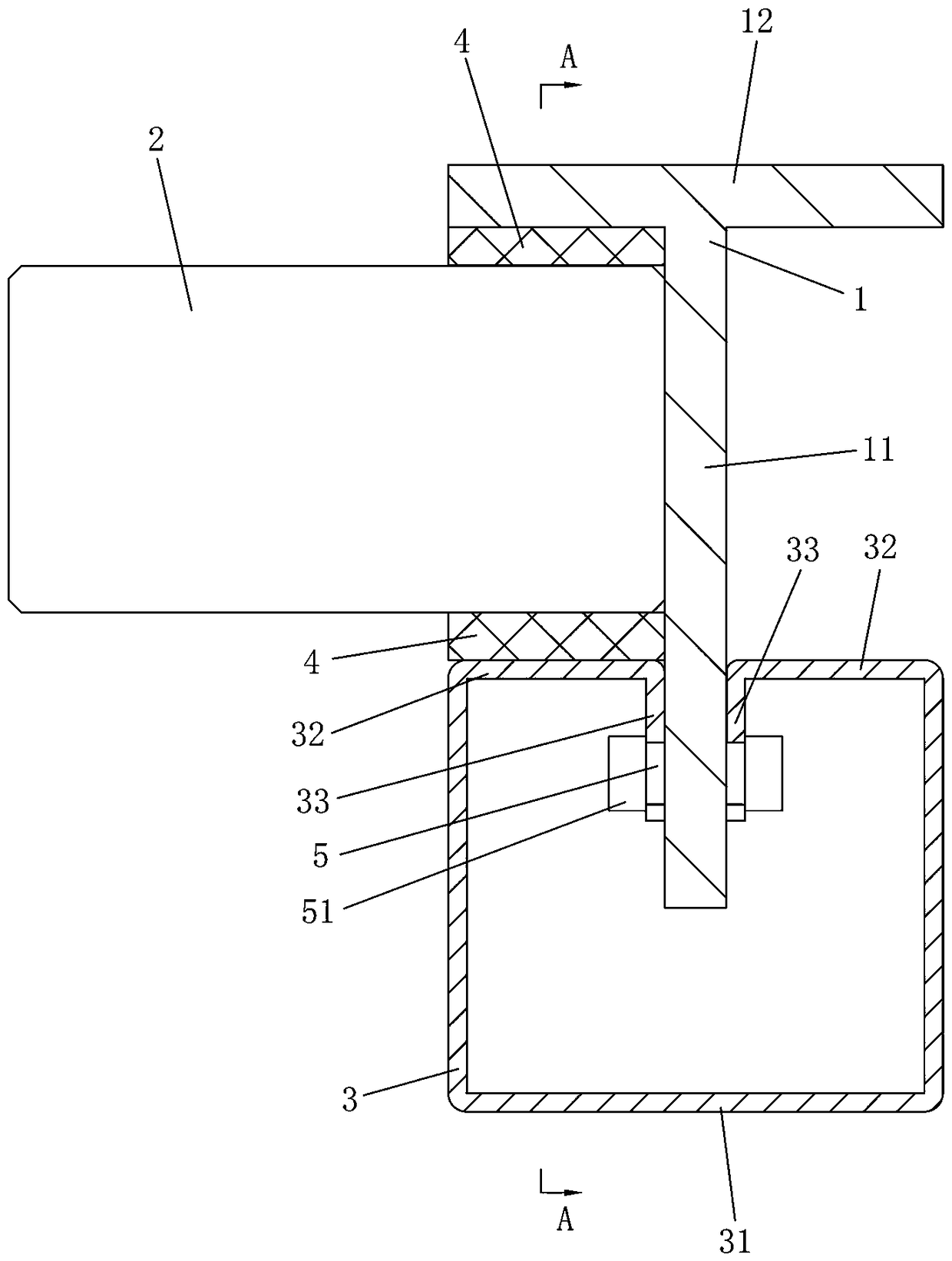

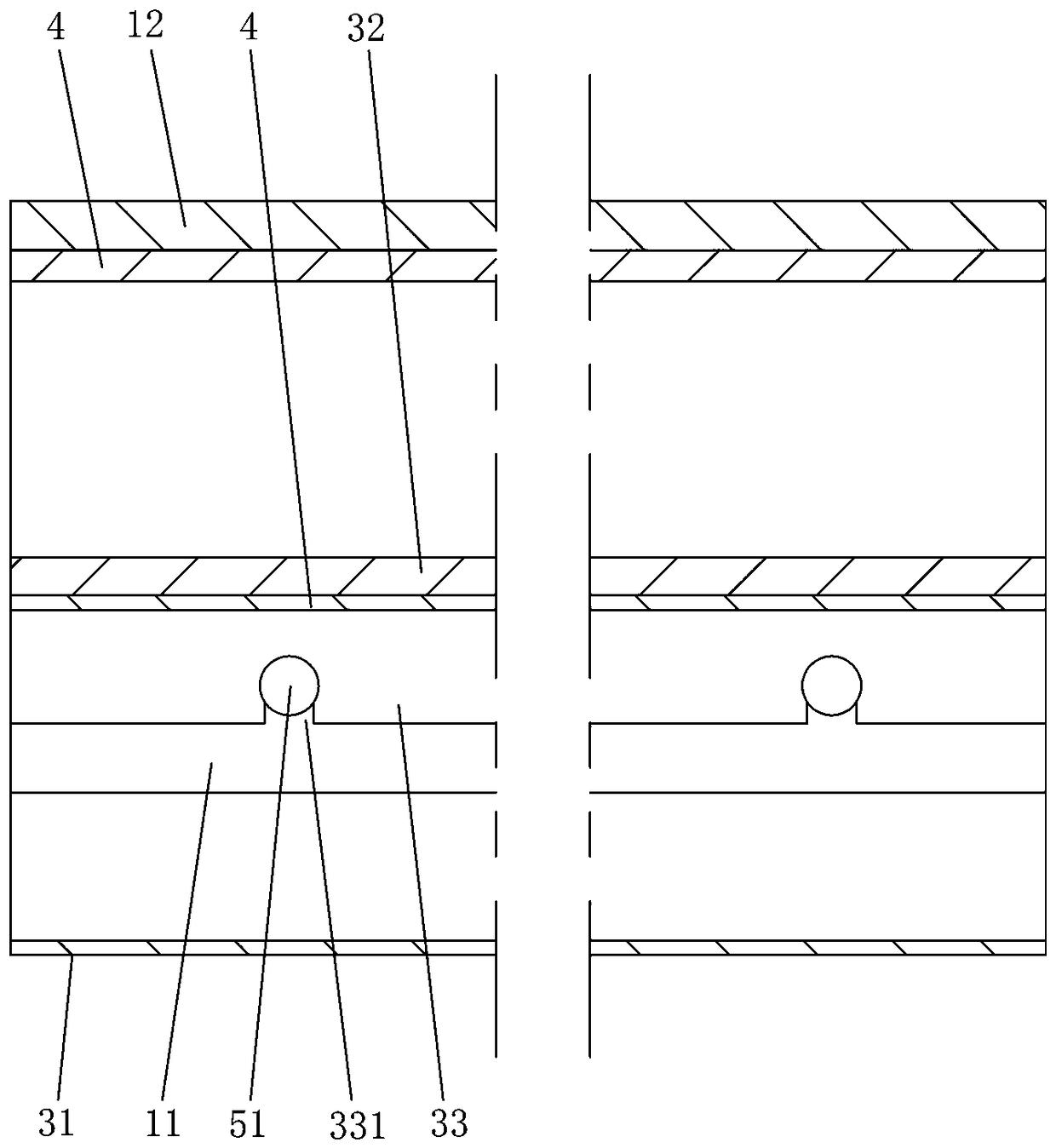

[0041] like Figure 1 to Figure 4 As shown, the fire-resistant glass wall of this embodiment includes a number of columns 1 arranged at intervals, and glass plates 2 are installed between two adjacent columns 1. The columns 1 are solid steel columns, and the columns 1 include trunks 11 connected as a whole. and side baffles 12, the glass plate 2 is placed between the trunks 11 of two adjacent uprights 1, and each upright 1 is connected with a detachable connecting assembly to press and fix the glass plate 2 on the side baffles 12. The first fireproof filler 4 is equally pressed between the pressing part 3 , the side block 12 and the glass plate 2 and between the pressing part 3 and the glass plate 2 . The column 1 of the fire-resistant glass wall adopts a solid steel column (heavy steel), and the glass plate 2 is pressed and fixed on the side block 12 of the column 1 by using the pressing part 3. The column 1 is the main force-bearing part, and its strength High, good load-be...

Embodiment 2

[0052] The fireproof glass wall of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as Figure 5 and Image 6 As shown, in this embodiment, the two anti-retraction parts 5 are connected as one piece, which is a bent sheet material, which is U-shaped as a whole, including a bottom plate and two side plates connected to both sides of the bottom plate, The bottom plate is fixedly connected to the main body 11 , and the two side plates are respectively located on both sides of the main body 11 as the limiting parts 33 . In addition, in this embodiment, each limiting portion 33 is not provided with a bayonet 331 . In this embodiment, the two backstopping parts 5 are connected into one piece, which is convenient to manufacture and install, and low in cost.

Embodiment 3

[0054] The fireproof glass wall of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as Figure 7 As shown, in this embodiment, the two anti-retraction parts 5 are respectively threaded on the main body 11, which is convenient for disassembly and assembly. In addition, in this embodiment, each limiting portion 33 is not provided with a bayonet 331 .

[0055] In this embodiment, a second fireproof filler 9 is provided between each column 1 and the glass plate 2 , which can further improve the fireproof sealing performance and avoid rigid contact between the column 1 and the glass plate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com