Heat exchanger and deep well heat exchange system thereof

A technology of heat exchangers and heat exchange tubes, applied in indirect heat exchangers, types of heat exchangers, heat transfer modification, etc. Inconvenient and other problems, to achieve the effect of simple structure, convenient control, compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

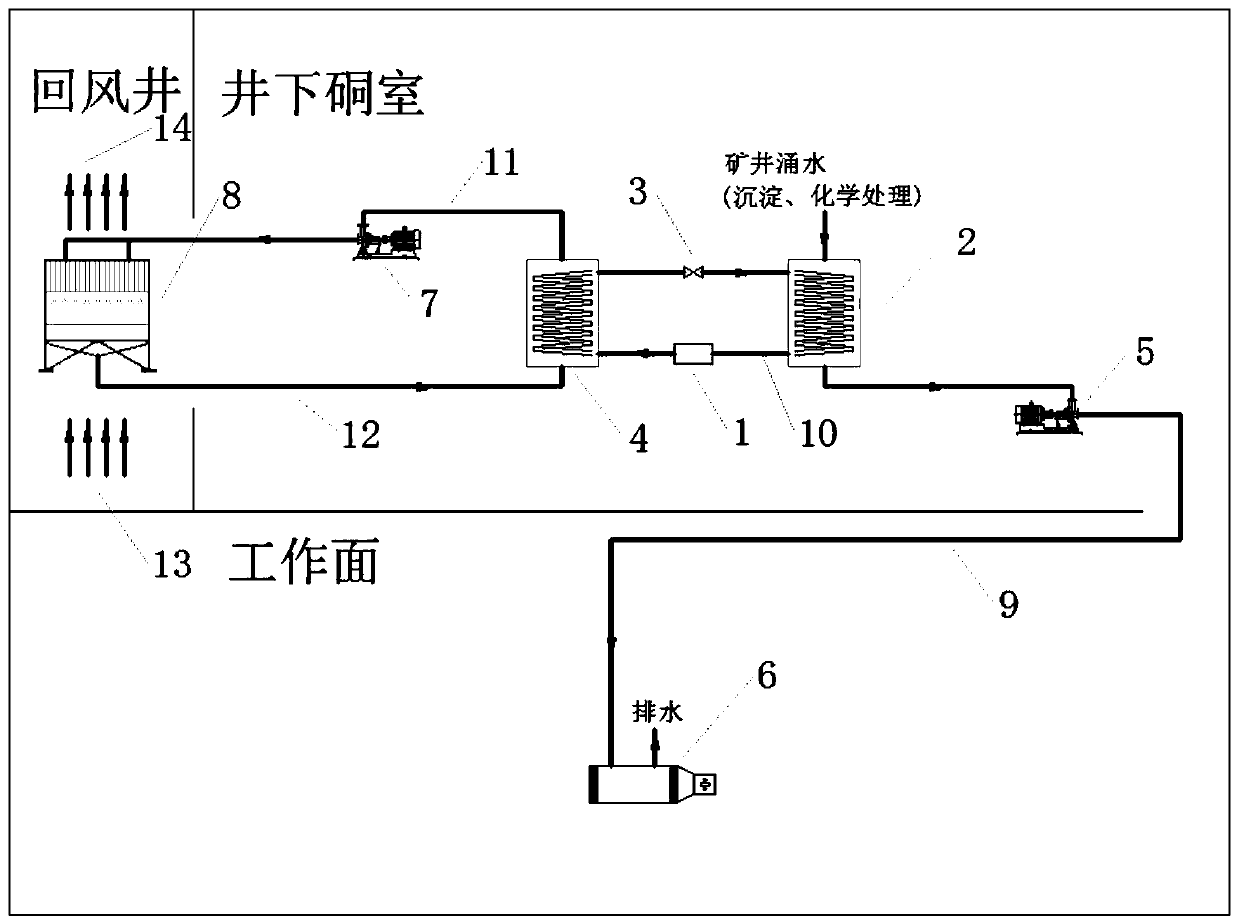

[0042] figure 1 A schematic diagram of the overall structure of a thermal system for deep mining is shown. Such asfigure 1 As shown, the thermal system of deep well mining includes three parts, which are the return air shaft part, the underground chamber part and the working face (mining area) part, in which the return air shaft part is equipped with a cooling tower 8, and the underground chamber part is equipped with an evaporator 2 , an expansion valve 3, a compressor 1 and a condenser 4, and the air cooler 6 is arranged on the working surface. The air cooler 6 is used to cool downhole air, and the evaporator 2, expansion valve 3, compressor 1, and condenser 4 constitute a refrigeration system; the cooling tower 8 and the condenser 4 constitute a circulation pipeline, and the air return shaft After the air in the cooling tower 8 exchanges heat with water, the water enters the condenser 4 through the pipeline, and exchanges heat with the refrigerant in the condenser 4. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com