Simulation test method of coal and gas outburst in coal-series rock stratum containing faults

A technology of gas outburst and simulation test, applied in the field of similar simulation test, to achieve the effect of flexible test method, various stress conditions and convenient installation

Active Publication Date: 2019-07-09

CHONGQING UNIV

View PDF8 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The existing coal and gas outburst simulation test devices and supporting test methods have a good simulation of the combined dynamic disasters of conventional co

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

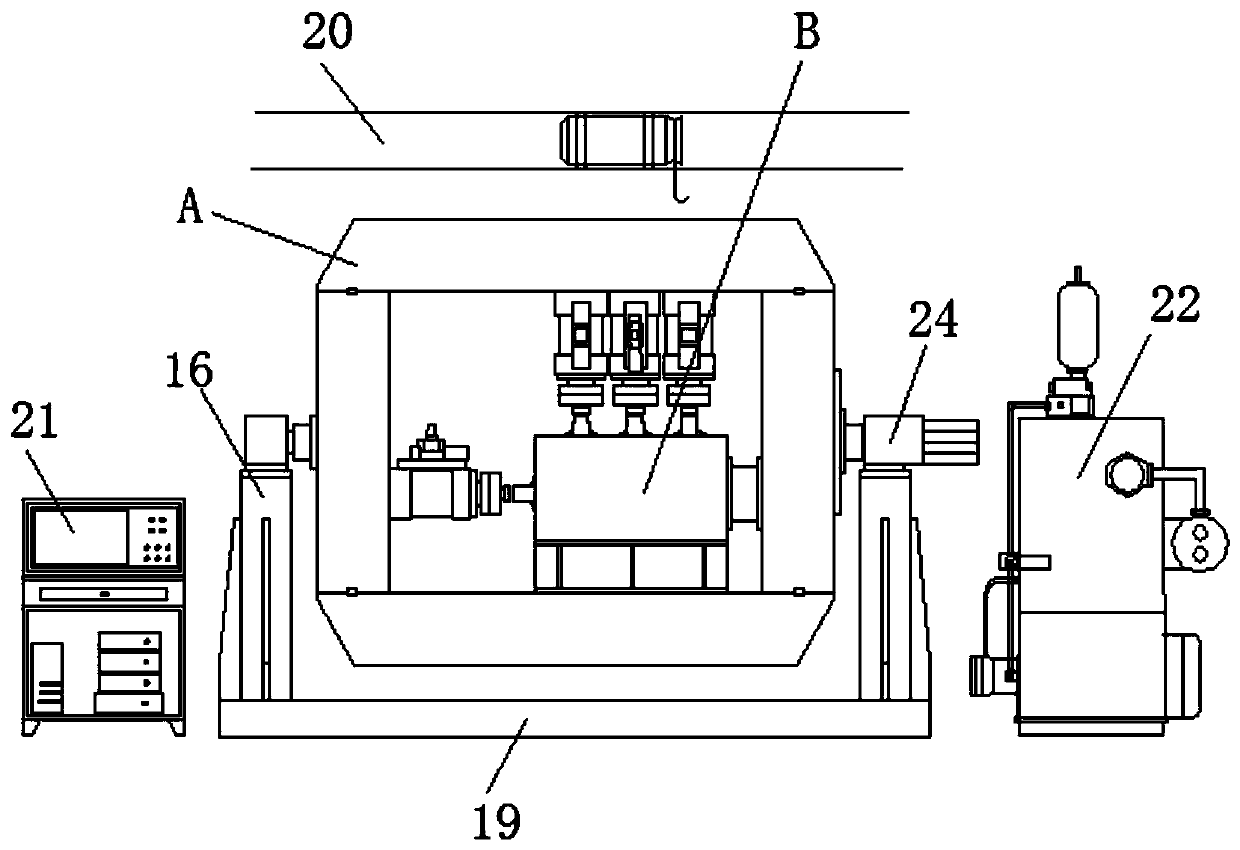

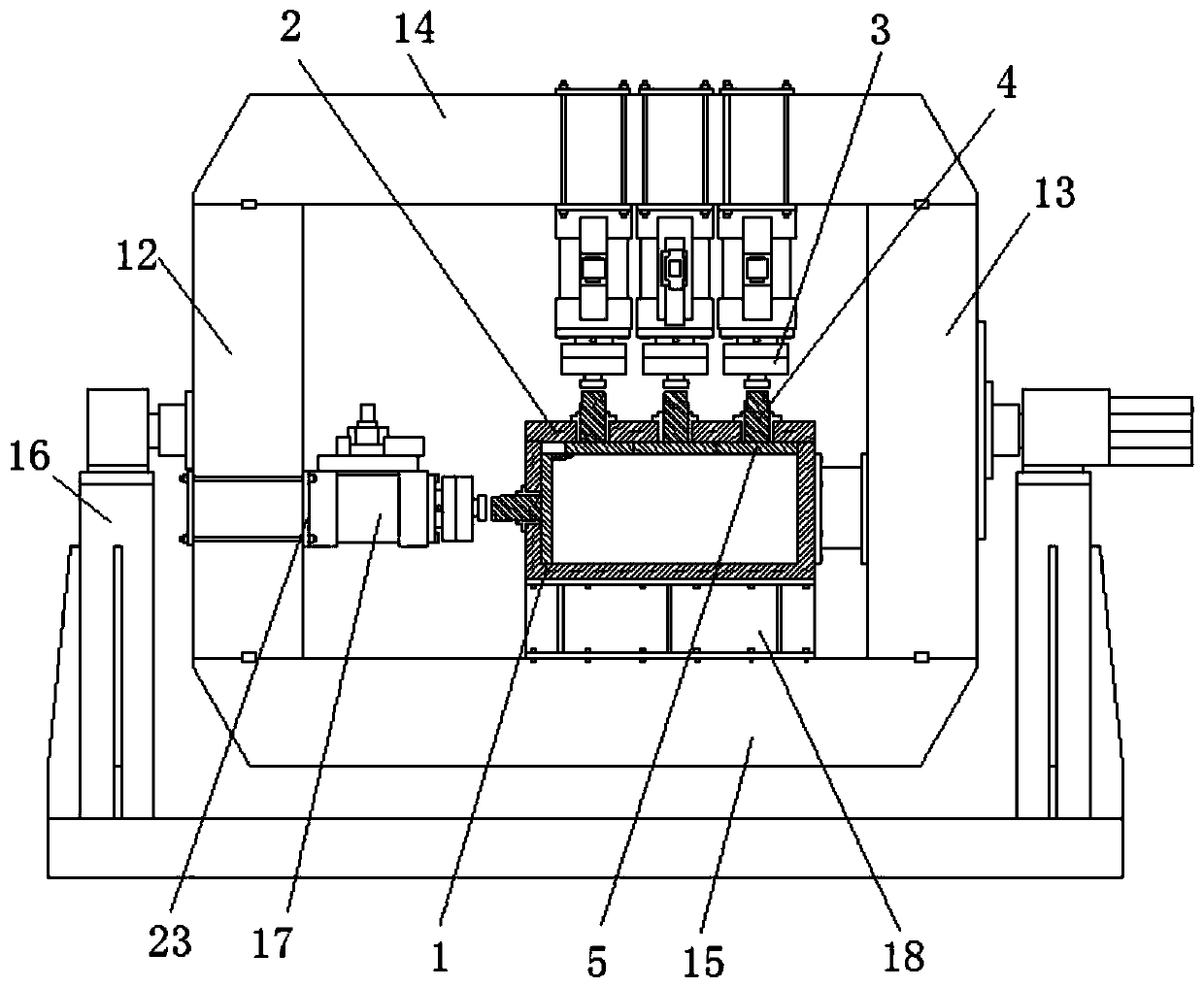

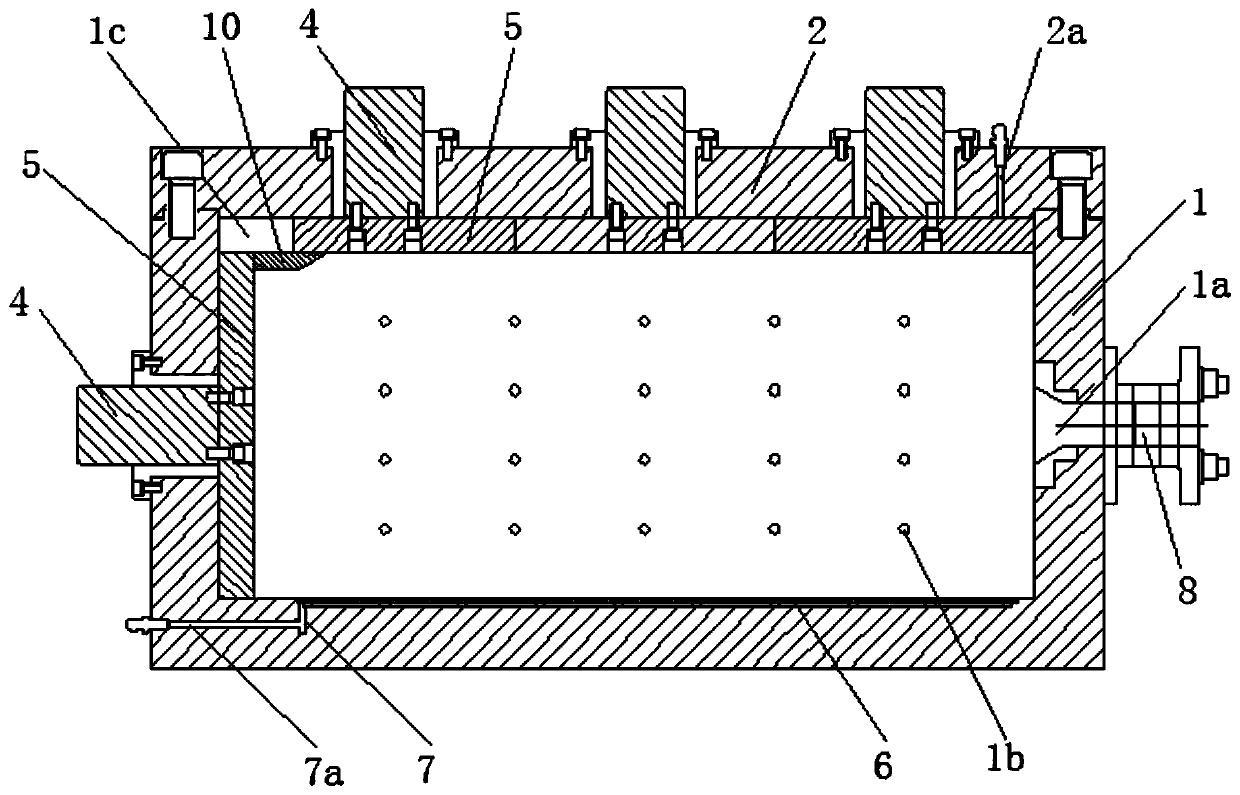

The invention discloses a simulation test method for coal and gas outburst in a coal-series rock stratum containing faults. The simulation test method for the coal and gas outburst in the coal-seriesrock stratum containing the faults comprises that steps that (1) experimental similar materials are prepared; a similar model of the coal-series rock stratum containing the faults is prepared; a test-piece box is installed; (4) a pressing head is in contact with the test-piece box; whether sensor connection is normal or not is inspected, and the test is prepared for being carried out; and (5) a two-dimensional dynamic and static combined loading similar simulation test is carried out and data is collected. According to the simulation test method for the coal and gas outburst in the coal-seriesrock stratum containing the faults, by using a two-dimensional combined stress-induced outburst simulation test device, static loading is carried out firstly, and dynamic loading and data collectionare carried out, and the loading of multiple stress waves of a coal and rock mass can be realized; compared with two types of dynamic load applying modes of a traditional hammer dropping mode and a Hopkinson rod mode, the test method of applying impact load is more flexible, and the stress conditions are more diverse; and combined with the preparation of the similar model of the coal-series rock stratum containing the faults, the mechanical property of a body of the coal-series rock stratum containing the faults can be better simulated under complex stress conditions.

Description

technical field [0001] The invention relates to a similar simulation test method for studying composite dynamic disasters of fault-containing coal measure rock formations. Background technique [0002] The similar model test refers to the physical test, through the corresponding test on the scaled down or proportional model, to obtain relevant data and check the design defects. A structural test in which a proportional load is applied to a test structure (or member) similar to the prototype made of appropriate proportions and similar materials, and the model is subjected to force before the actual work of the prototype structure is performed. The test object is a test representative modeled on the prototype (actual structure) and reproduced according to a certain scale, which has all or part of the characteristics of the actual structure. It is an important experimental research method to conduct experimental research with a model similar to the prototype and apply the rese...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N33/24

CPCG01N33/24

Inventor 张东明叶辰尹光志李树建楚亚培叶茂林杨邦友李小明肖伟晶金磊

Owner CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com