Processing parameter optimization method for reducing mounting error sensitivity of hypoid gear

A hypoid gear, installation error technology, applied in the direction of gear transmission, components with teeth, belt/chain/gear, etc., can solve the problem of lack of hypoid gear pair analysis, inability to compare the impact of gear pair meshing performance , failed to raise the problem of reducing hypoid gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0092] Taking a pair of hypoid gear pairs with an offset distance of 38 mm as an example, the number of teeth of the large wheel is 7, and the number of teeth of the small wheel is 36. The basic geometric parameters are shown in Table 1. The processing parameters of the large wheel machine tool calculated according to the Gleason method are shown in Table 2, the initial processing parameters of the small wheel are shown in Table 10.

[0093] Table 1. Geometric parameters of hypoid gear pair

[0094]

[0095]

[0096] Table 2. Large wheel processing parameters

[0097]

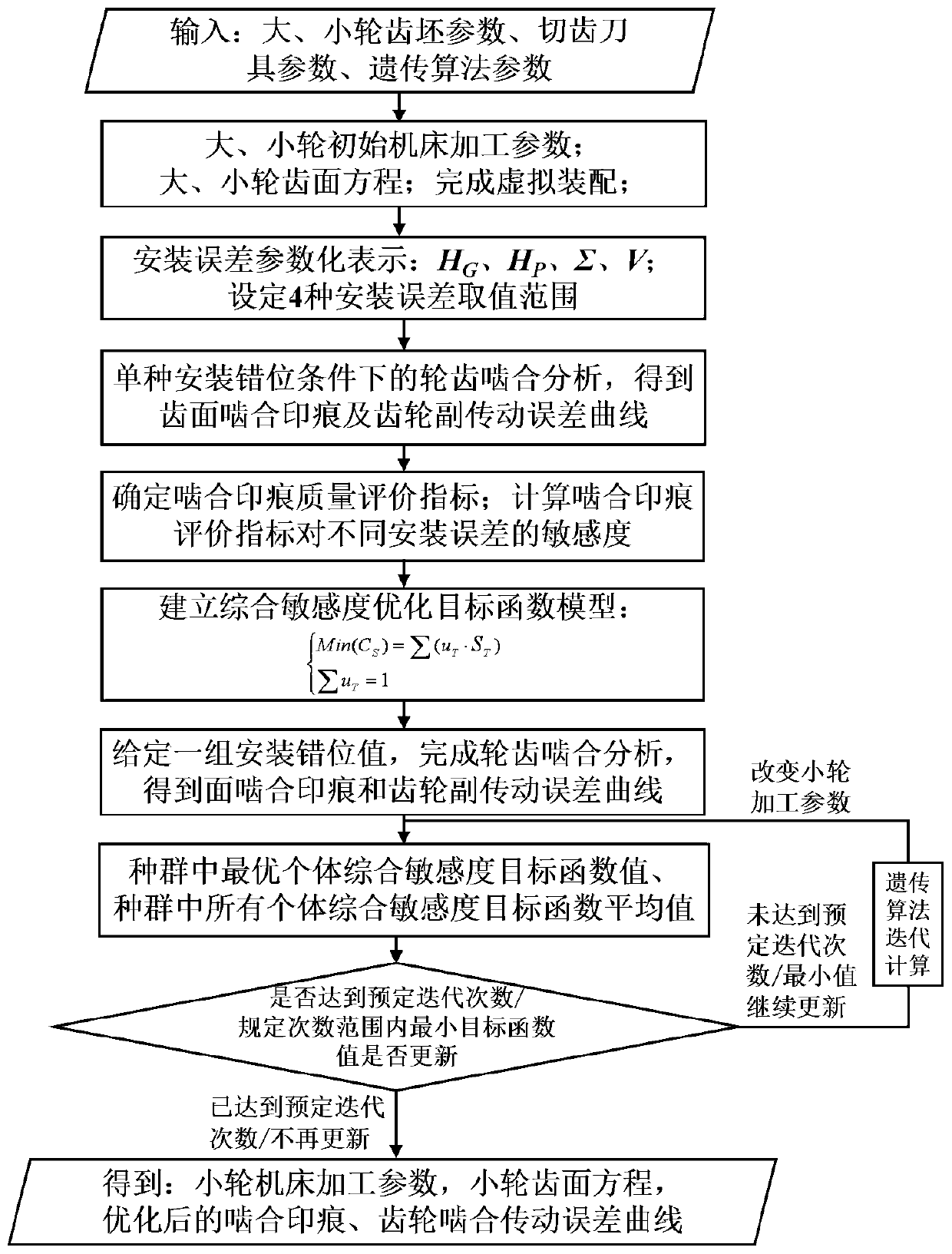

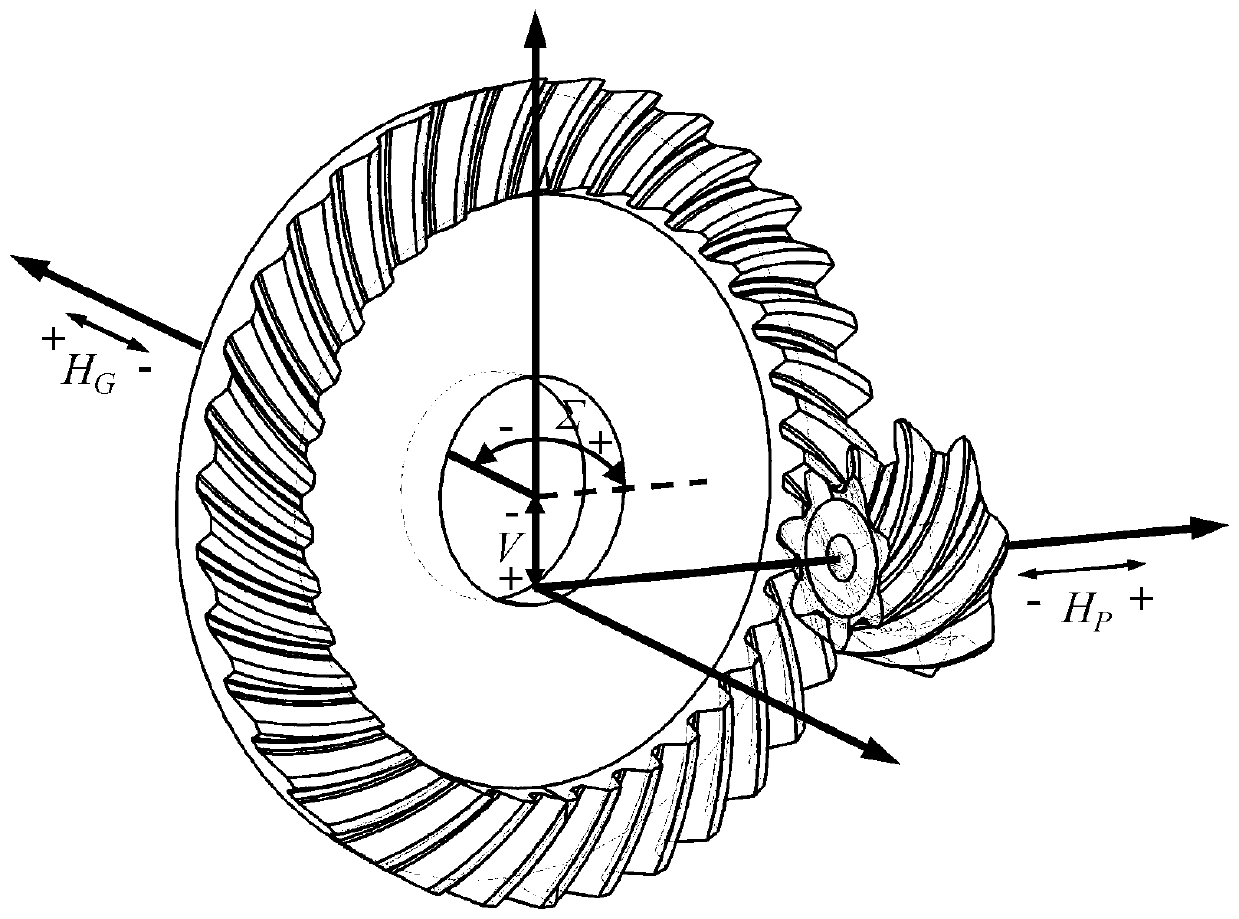

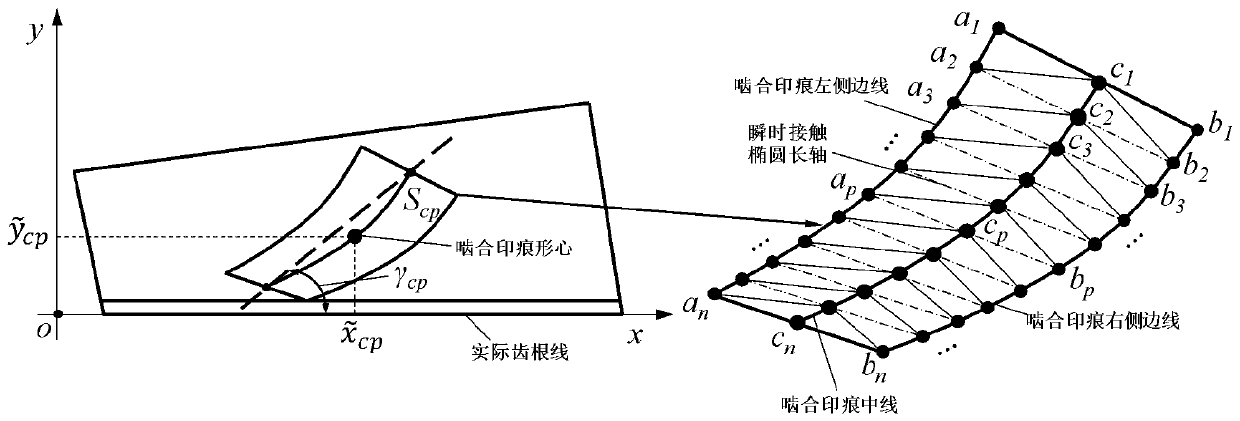

[0098] figure 1 General flowchart of the method of the present invention, figure 2 It is a schematic diagram of the installation error of the hypoid gear pair in the method of the present invention, and the parameters of the installation error amount of the gear pair are given in Table 3. image 3 It is a schematic diagram of the parametric representation of the meshing impression in the method of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com