Automatic vending machine and commodity conveying method

A technology for vending machines and commodities, applied in the directions of coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc. Affect the movement of the cargo bucket and other issues, to avoid collisions and ensure normal movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

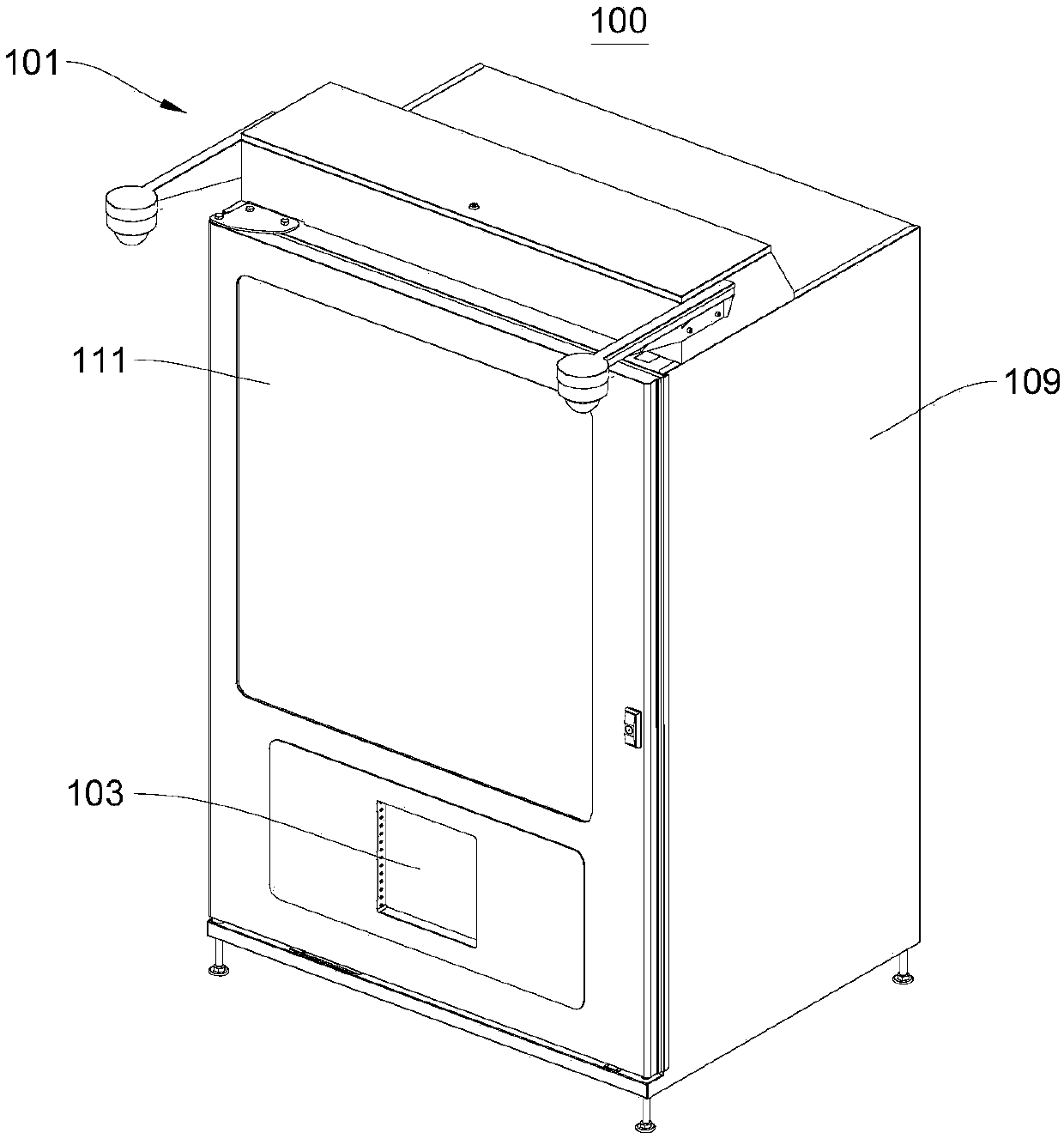

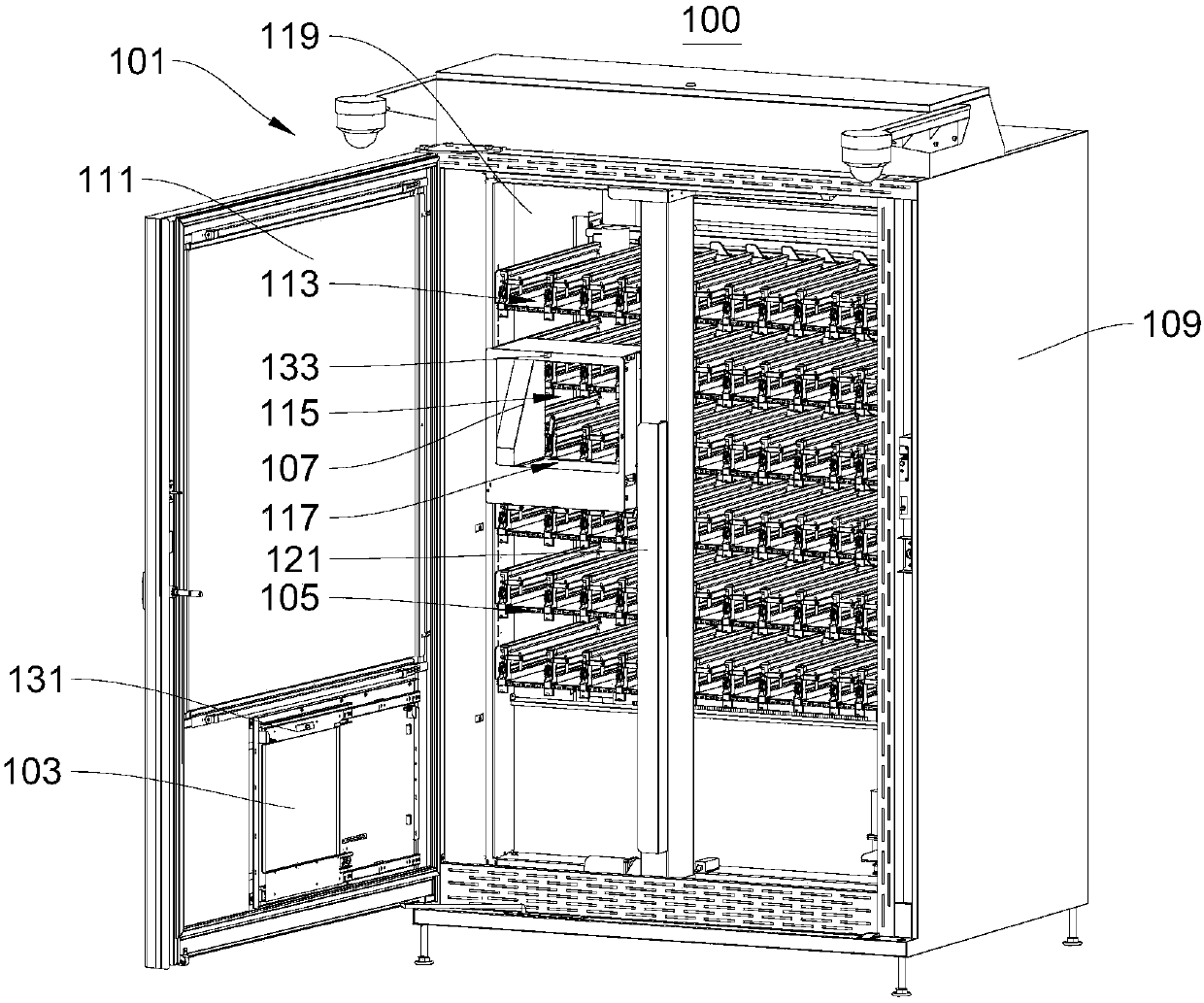

[0051] figure 1 A schematic structural diagram of the first state of the automatic vending machine 100 provided in this embodiment. figure 2 A schematic structural diagram of the second state of the automatic vending machine 100 provided in this embodiment. See 1 and figure 2 , in this embodiment, the automatic vending machine 100 includes a cabinet 101, a plurality of aisles 105 arranged in the cabinet 101, a cargo bucket 107, a bucket driving mechanism 121, a first door stop mechanism 123, a second door stop mechanism 125 and the controller.

[0052] see again figure 1 and figure 2, the cabinet 101 includes a cabinet body 109 , a cabinet door 111 and a storage device 119 . The cabinet door 111 is rotatably connected with the cabinet body 109 . The surface of the cabinet door 111 is provided with a pick-up port 103 . The material of the cabinet door 111 can be made of transparent material, so as to display the commodities in the cabinet body 109 . The cargo storage...

Embodiment 2

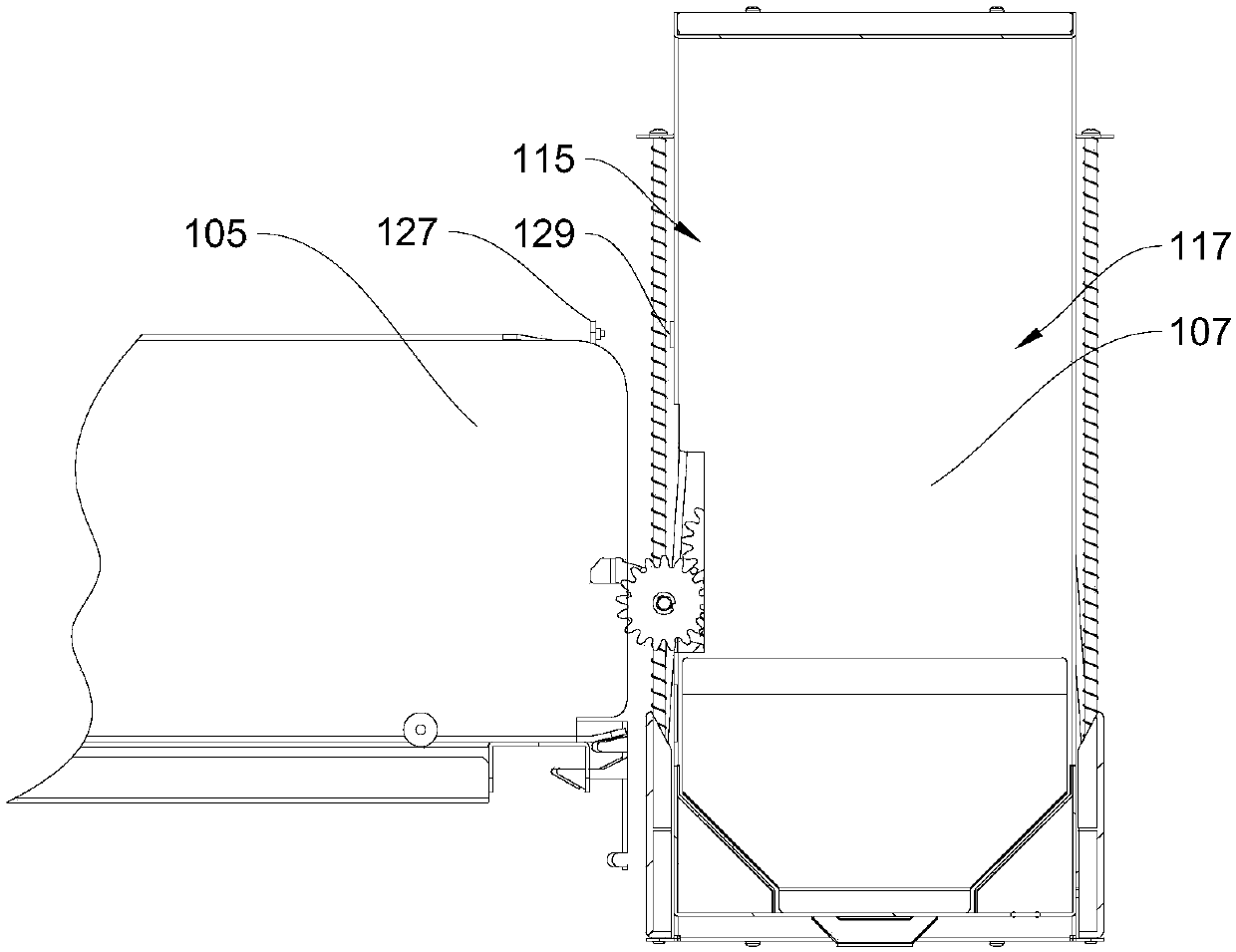

[0066] This embodiment provides a commodity delivery method, which is applied to an automatic vending machine 100. The automatic vending machine 100 includes a cabinet 101, a cargo bucket 107, a first door stop mechanism 123, a second door stop mechanism 125 and a plurality of cargo lanes 105, The cabinet 101 is provided with a pick-up port 103, a cargo bucket 107 and a cargo lane 105 are arranged in the cabinet 101, the cargo bucket 107 has a relative cargo inlet 115 and a cargo outlet 117, and a first door blocking mechanism 123 is arranged at the cargo inlet 115. , the second door blocking mechanism 125 is arranged at the outlet 117 . Figure 8 It is a schematic flowchart of the commodity delivery method provided in this embodiment. see Figure 8 , the product delivery method includes the following steps:

[0067] S1: Control the cargo bucket 107 to move to the target cargo lane, so that the cargo inlet 115 is docked with the target cargo lane;

[0068] Wherein, when usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com