Battery cell supporting component

A battery cell and component technology, which is applied to the field of battery cell supporting components for battery modules, can solve the problems of large occupied volume, poor heat dissipation effect of battery modules, and low assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

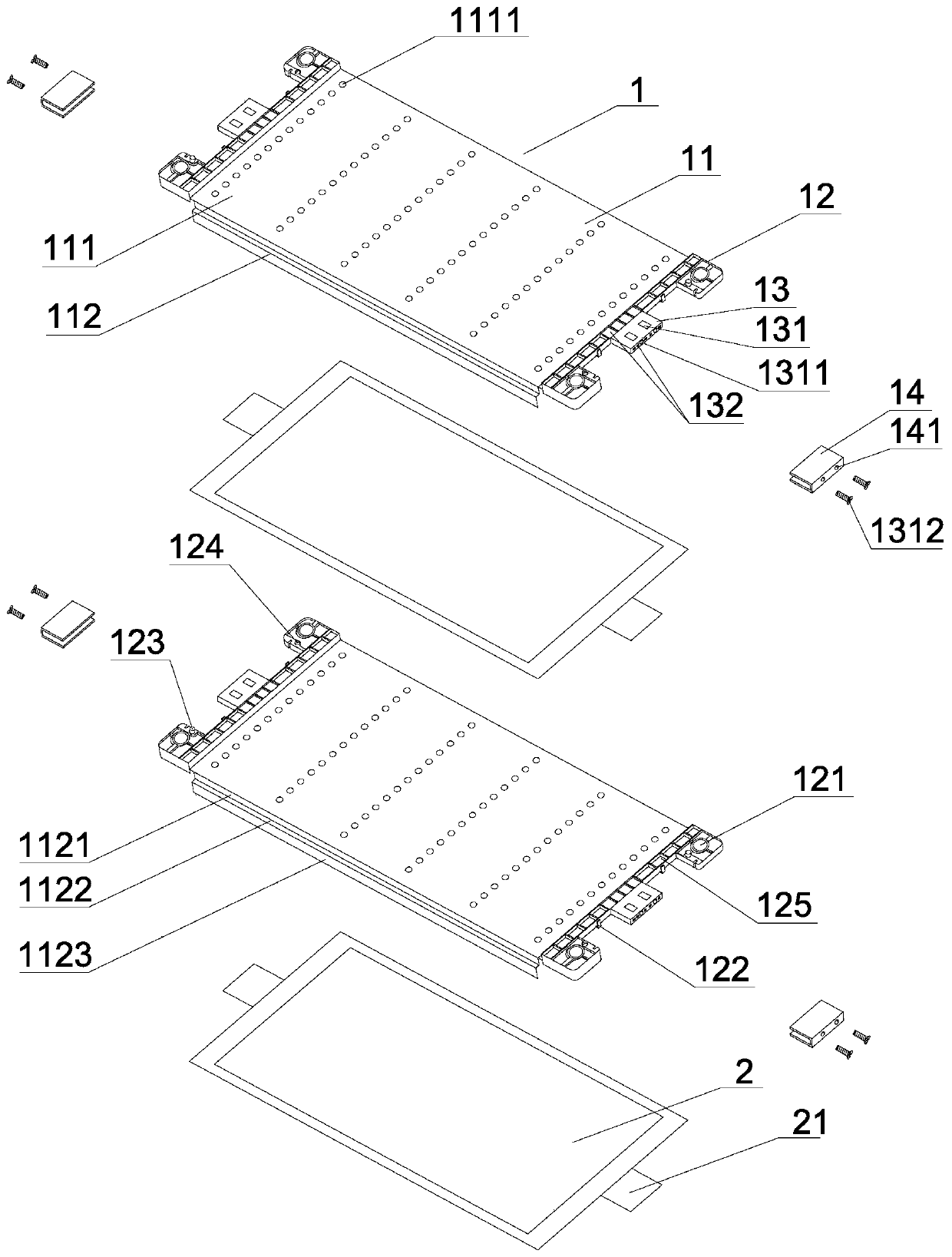

[0051] Such as figure 1 As shown, the present invention provides a cell supporting part 1 for a battery module. The cell supporting part 1 includes a heat conducting plate 11. The heat conducting plate 11 includes a heat conducting plate main body 111 and a heat conducting plate side plate 112. The heat conducting plate main body 111 and The side plate 112 of the heat conduction plate is integrally formed and forms a groove structure, so that the assembly efficiency of the cell supporting part 1 is higher, the weight is reduced, and the energy density is higher. The groove structure also makes the cell more stable and safer. The heat conduction plate main body 111 is provided with openings 1111 arranged in a rectangular manner, so that the deformation and weight of the heat conduction plate main body 111 are reduced, and it is also conducive to heat exchange between adjacent battery cells 2 to keep the temperature balance between the battery cells 2 . The heat conduction plate...

Embodiment 2

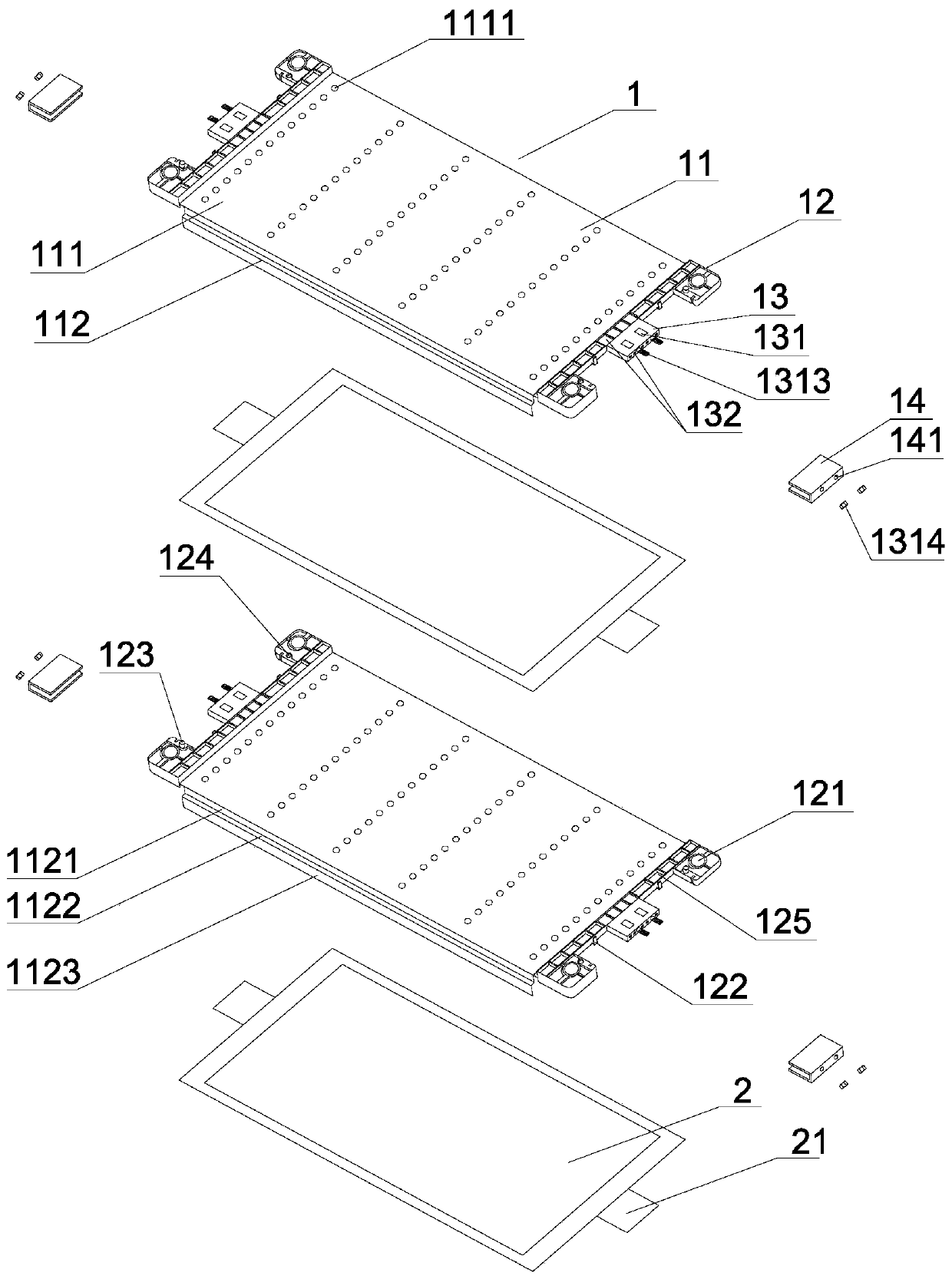

[0056] figure 2 It is the structural representation of embodiment two. The difference between the second embodiment and the first embodiment is that the material used for the heat conduction plate main body 111 and the heat conduction plate side plate 112 is metal, and this metal is an iron-copper alloy. The material of the end plate 12 and the lug supporting flow guide 13 is an insulating material, and this insulating material is PP. A stud 1313 is provided on the metal post cap 131 , and a through hole 141 is correspondingly provided on the busbar 14 . The bus piece 14 and the lug 21 are fixedly connected by welding, the stud 1313 passes through the through hole 141 on the bus piece 14, cooperates with the bolt 1414, and the bus piece is firmly fixed on the metal column cap 131 through the stud bolt structure, so that The tab 21 is firmly fixed on the tab supporting deflector 13 . The metal post cap 131 is in direct contact with both the tab 21 and the busbar 14, which i...

Embodiment 3

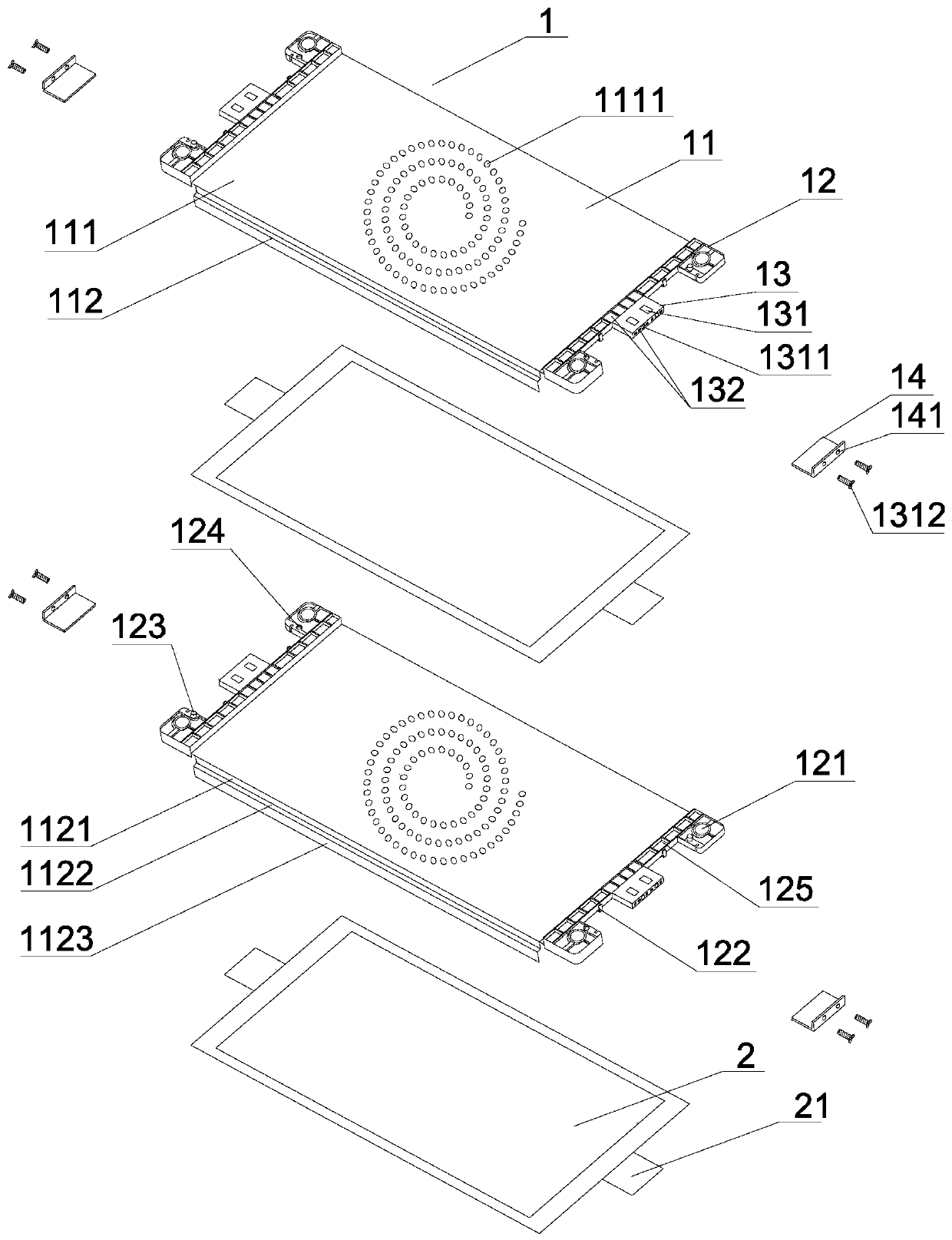

[0058] image 3 It is a structural schematic diagram of embodiment three. The difference between the third embodiment and the first embodiment is that the main body 111 of the heat conduction plate is provided with openings 1111 arranged in a spiral shape, so that the deformation and weight of the main body 111 of the heat conduction plate are reduced, and it is also beneficial to the heat dissipation between adjacent cells 2. Exchange to keep the temperature balance between cells 2. The busbar 14 is L-shaped, further reducing the weight of the battery module.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap