Cell contacting system for an electrochemical device

A contact system, electrochemical technology, applied in electrochemical generators, electrical components, batteries, etc., can solve problems such as functional limitations, and achieve the effect of simplified installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

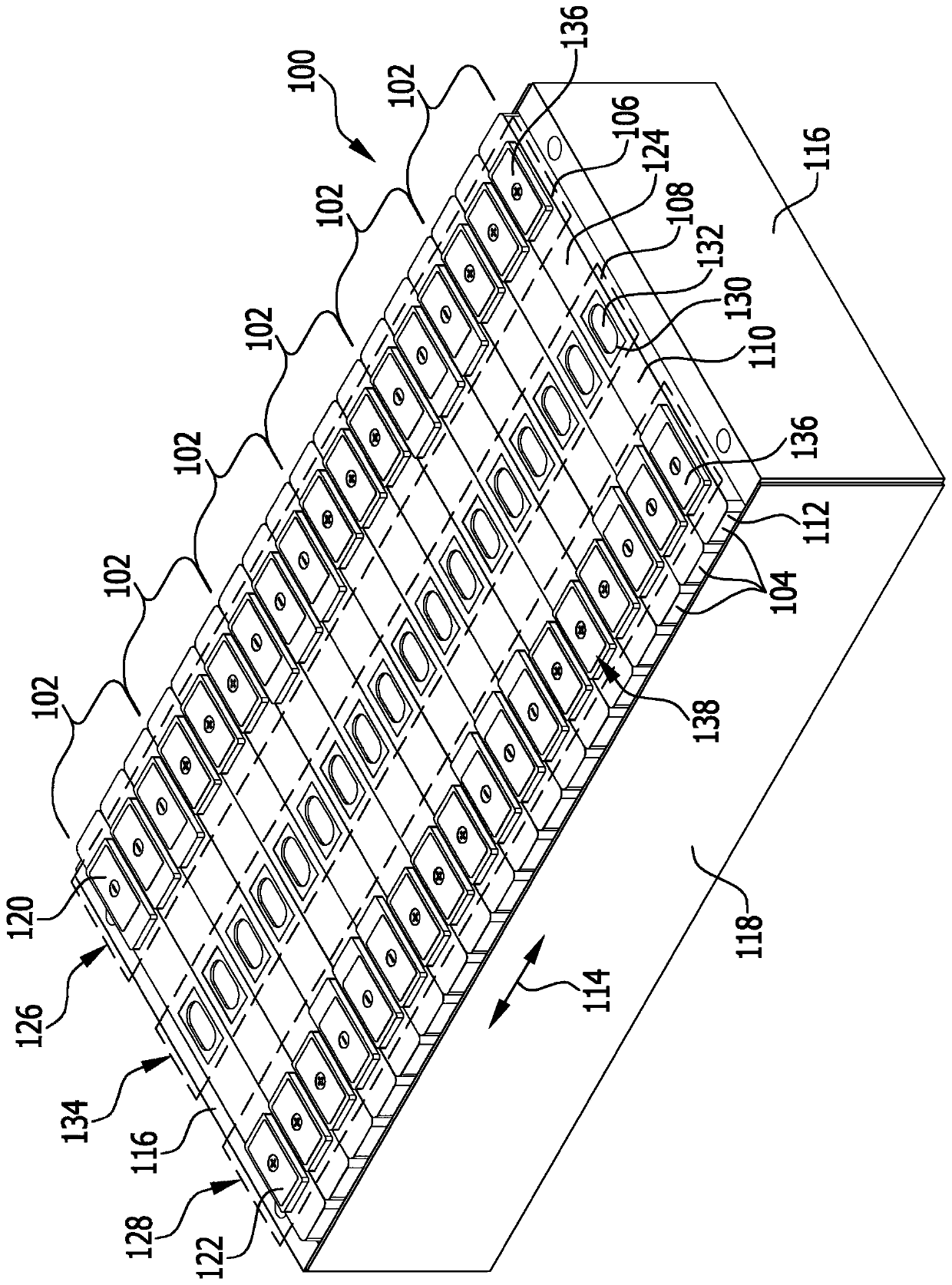

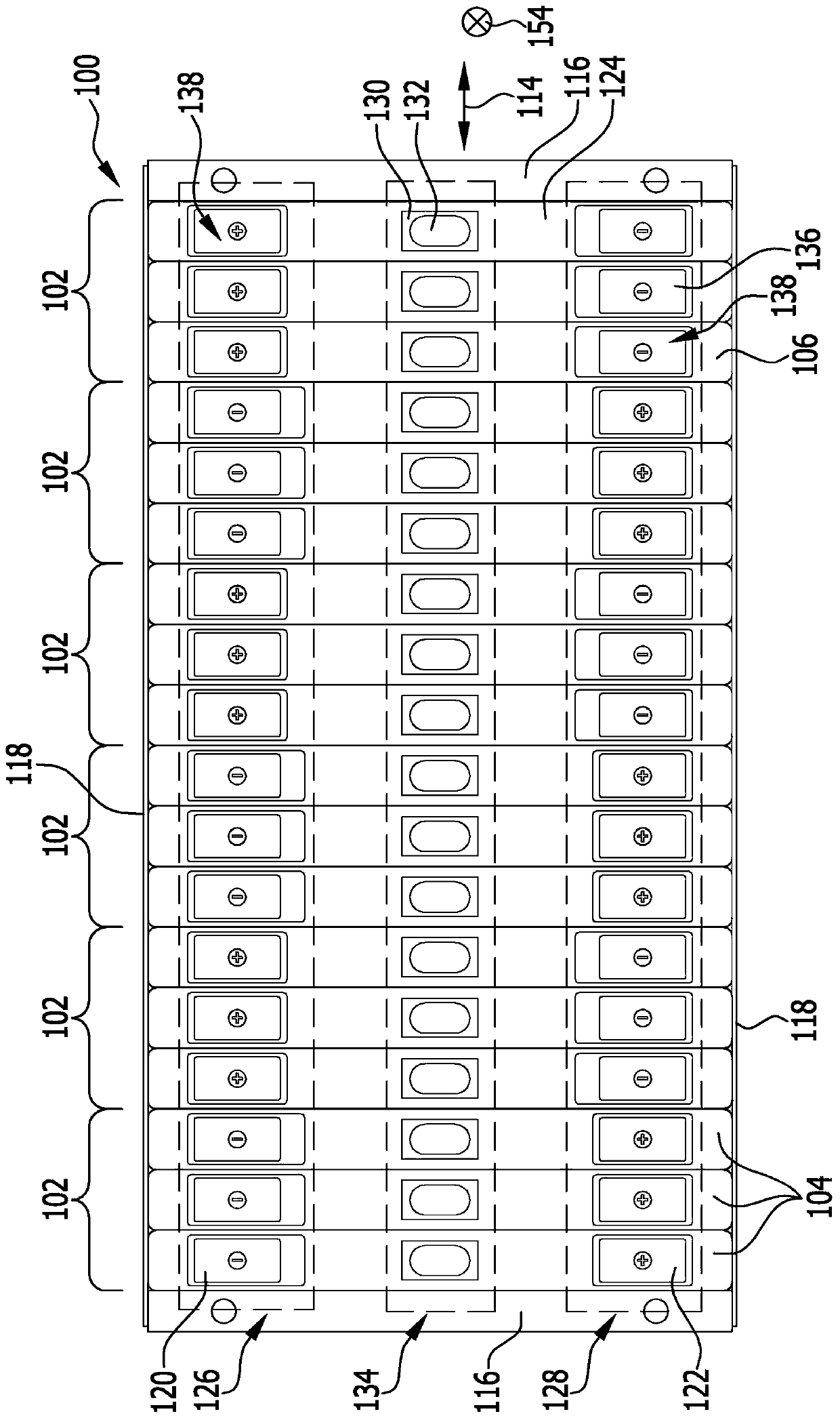

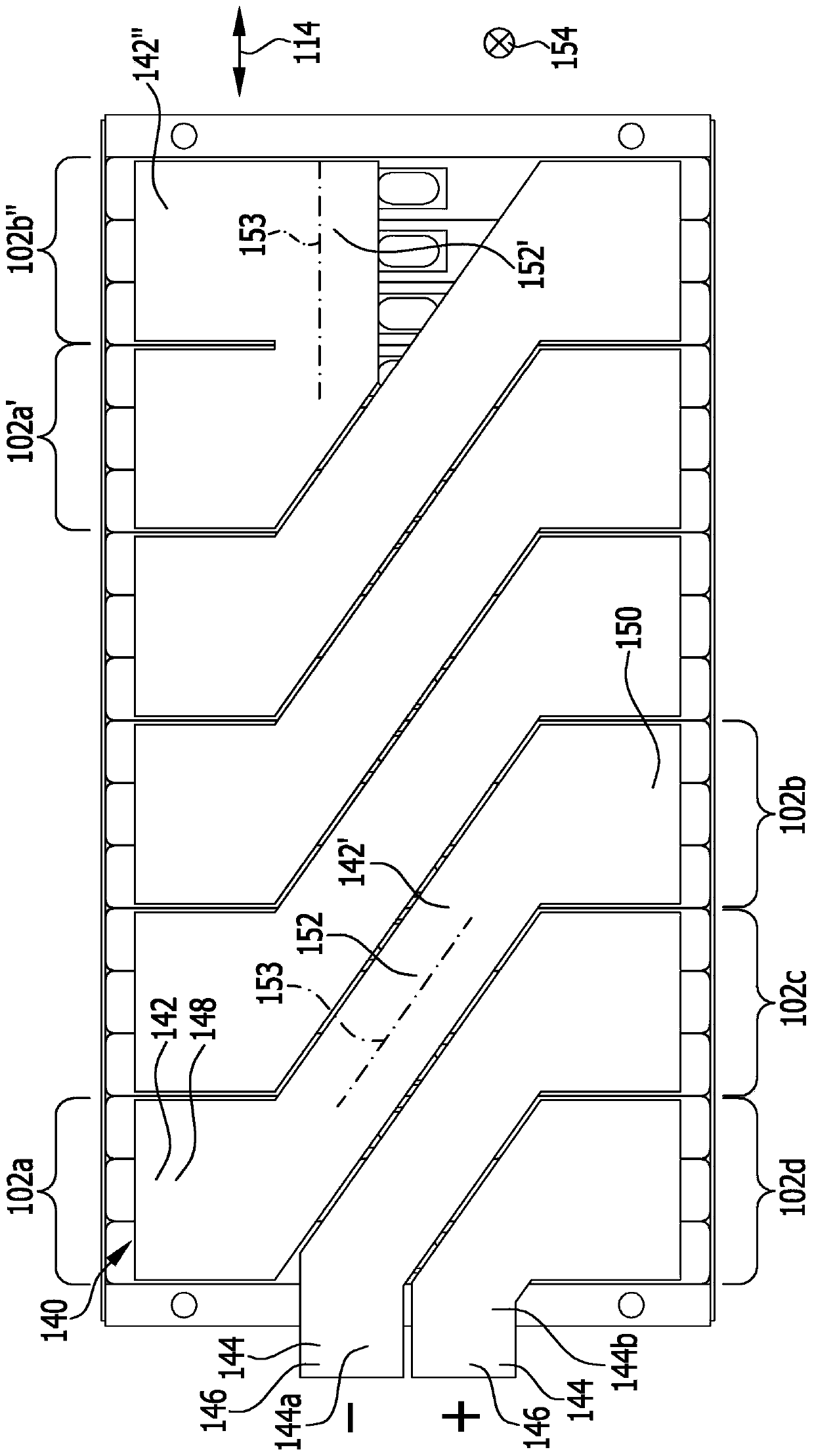

[0105] exist figure 1 and 2 The electrochemical device shown in , marked as a whole with 100, comprises a plurality, in the illustrated embodiment, six unit groups 102, each comprising a plurality, in the illustrated embodiment, respectively three The electrochemical unit 104.

[0106] Each electrochemical cell 104 has a prismatic, in particular substantially cuboid, housing 106, wherein the housing 106 each has two opposite wide sides 108, two opposite long sides A narrow side 110 and two respectively opposite short narrow sides 112 .

[0107] The electrochemical units 104 of an electrochemical device 100 such as a battery module are arranged successively along the longitudinal direction 114 of the electrochemical device 100, wherein every two electrochemical units 104 arranged successively along the longitudinal direction 114 have a width of one of them respectively. The side surfaces 108 bear against each other substantially flat and preferably substantially congruently....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com