Automatic self-adapted monitoring signal polarity laser control loop circuit

A technology for monitoring signals and controlling loops, which is applied to lasers, laser components, semiconductor lasers, etc., and can solve problems such as unfavorable delays and high circuit costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

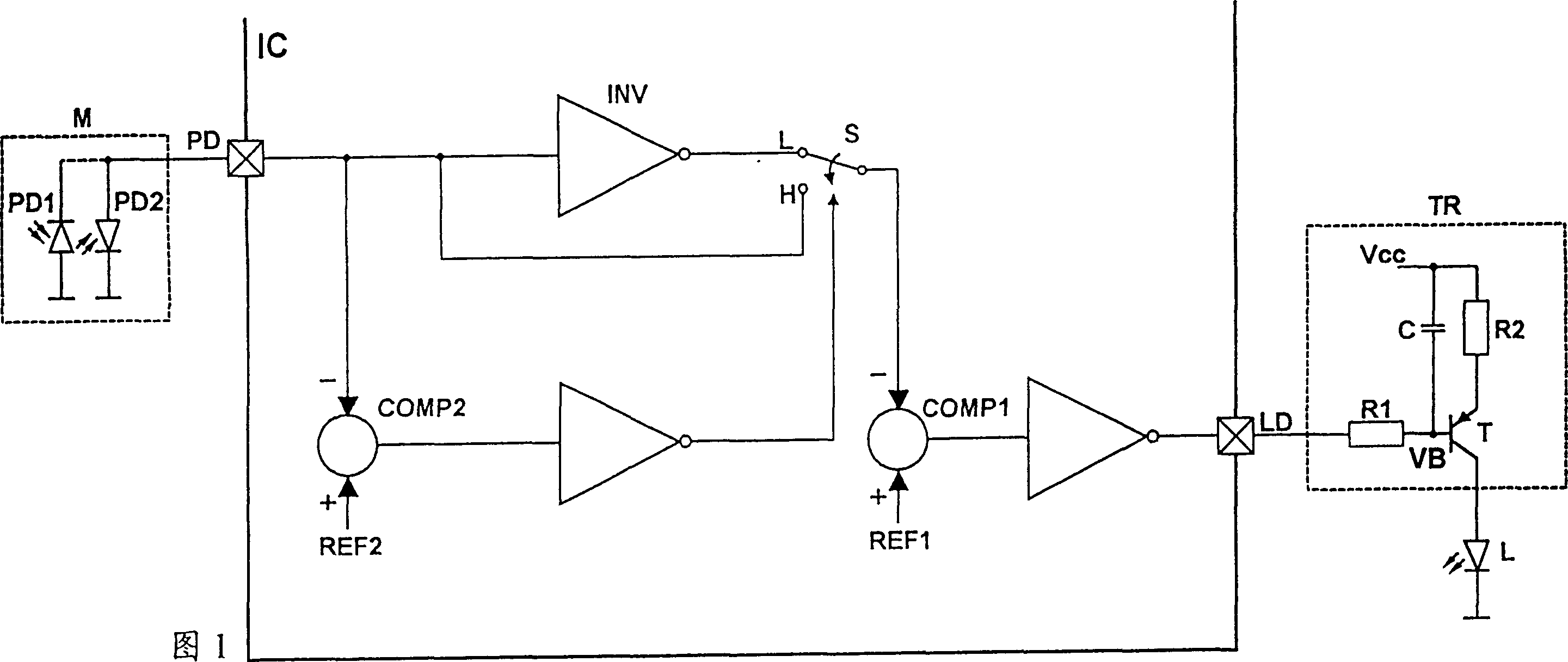

[0032]Figure 1 illustrates a block diagram of an optical power control loop for automatically adapting the polarity of the monitor signal, showing a monitor M fed to it at least a portion of the optical power for controlling the optical power or intensity of a light source L. The monitor M is formed by a photodetector which, depending on the type and connection of the photodetector, generates a positive or negative monitoring signal, the absolute value of which corresponds to the optical power of the light source L. The monitor M shown with a dotted box in Fig. 1 is two photodiodes PD1, PD2, the connection of their anode or cathode to the frame instructs the monitor M to generate a positive or negative monitor signal. The photodetector signal PD provided by the monitor M is fed to the input of the circuit IC for optical power control with automatic adaptation to the polarity of the monitor signal. In the area defined by the thick lines in Fig. 1 there is given a block diagram ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com