Liquid discharging method of food processing machine

A technology for food processing machines and drainage pipes, which is used in household appliances, applications, kitchen appliances, etc., can solve problems such as scalding consumers, avoid waste and pollute the environment, improve logic, safety, reliability, and intelligence. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

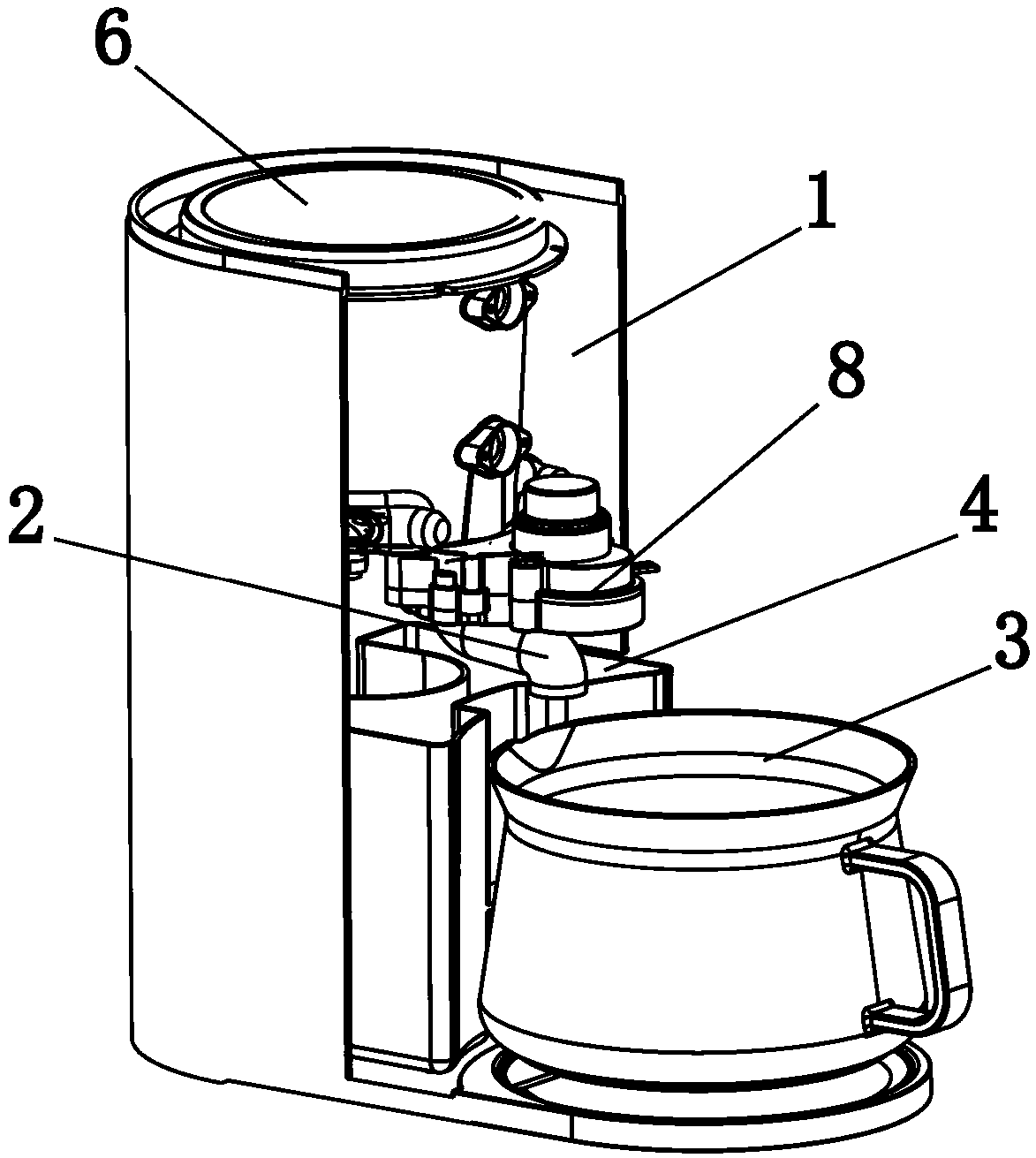

[0043] Such as Figure 4 , Figure 5 , Figure 6 Shown is a schematic structural view of the first embodiment of the food processor drain valve assembly of the present invention.

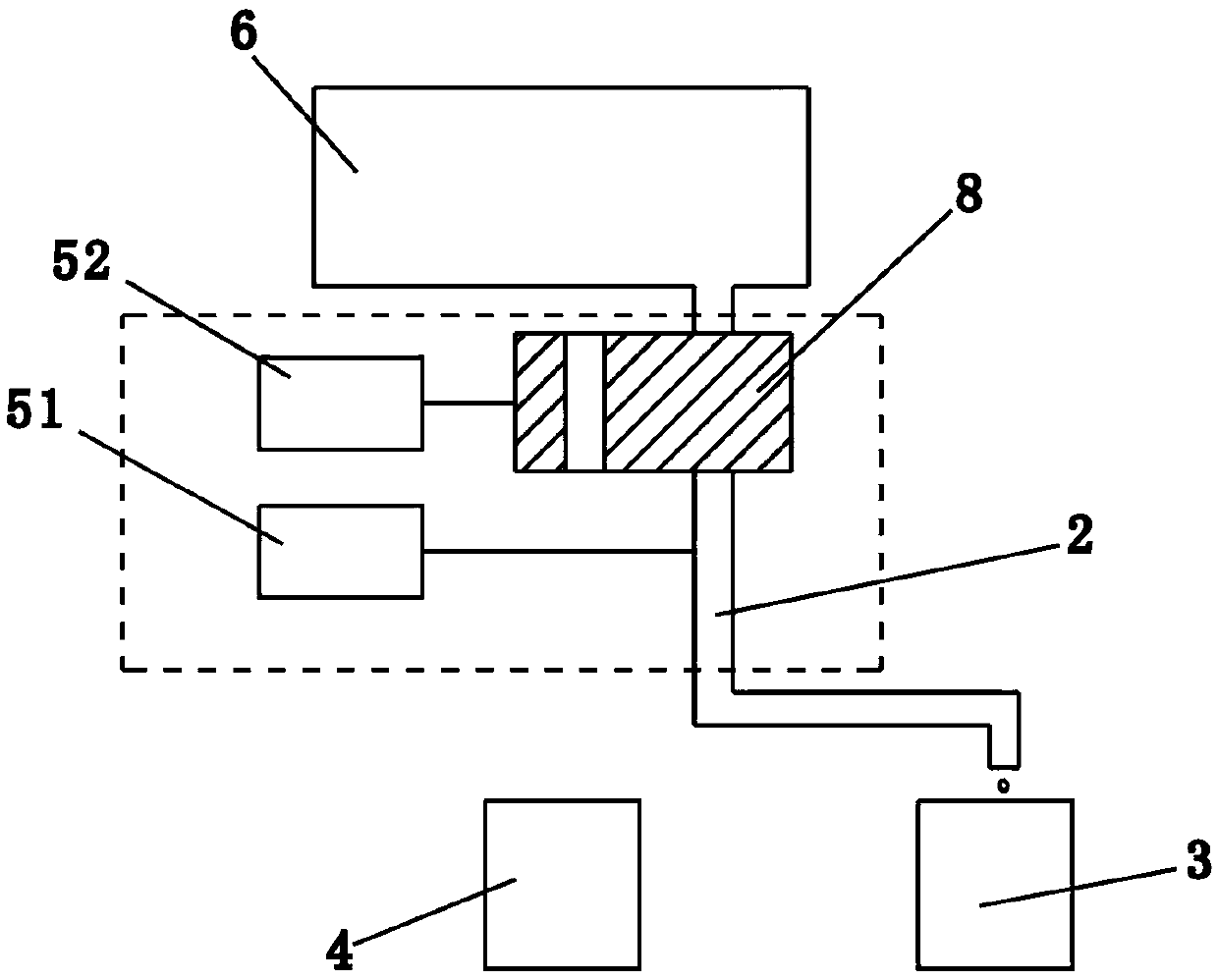

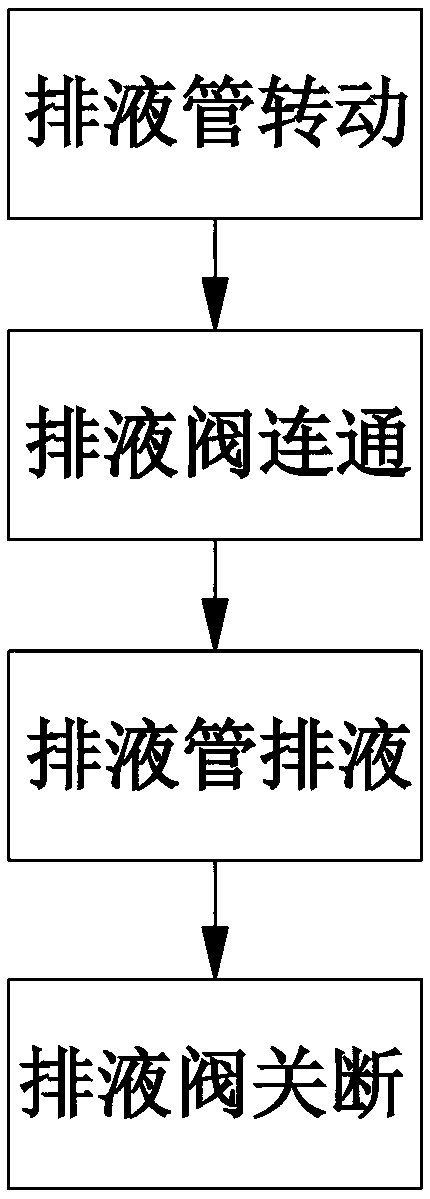

[0044] In this embodiment, the liquid discharge valve assembly further includes a driven assembly 7 that drives the liquid discharge pipe 2 to rotate, and the driven assembly 7 includes an intermediate gear 71 and a driven gear 72, wherein the intermediate gear 71 is driven by the first driving device 51 , the driven gear 72 is driven to rotate by the intermediate gear 71, and the drain pipe 2 passes through the driven gear 72 and is connected with the driven gear 72 as a whole, and the drain pipe 2 rotates following the rotation of the driven gear 72. The liquid discharge valve 8 includes a valve core with a communication hole 80, and the valve core is driven by the second driving device 52, and the communication hole 80 is used for the valve core to communicate with the pulping container and the...

Embodiment 2

[0060] Such as Figure 7 , Figure 8 As shown, it is a structural schematic diagram of the second embodiment of the food processor drain valve assembly of the present invention. In this embodiment, the first driving device 51 and the second driving device 52 are driven by the same motor 50 to run. The difference between this embodiment and the first embodiment is that the first driving device 51 is a first incomplete gear, the second driving device 52 is a second complete gear, and the planar movable valve plate 81 is driven by the second complete gear, and the planar movable valve plate 81 is driven by the second complete gear. There is only one communication hole 80 on the valve plate 81, and the discharge pipe 2 is connected to the communication hole 80. Wherein, while the first incomplete gear drives the driven assembly, the second complete gear also synchronously drives the planar movable valve plate 81 to work. , when the first incomplete gear rotates to disengage from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com