Liquid distributing structure of distillation equipment

A technology of distillation equipment and liquid distribution, which is applied in the field of liquid distribution structure of distillation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

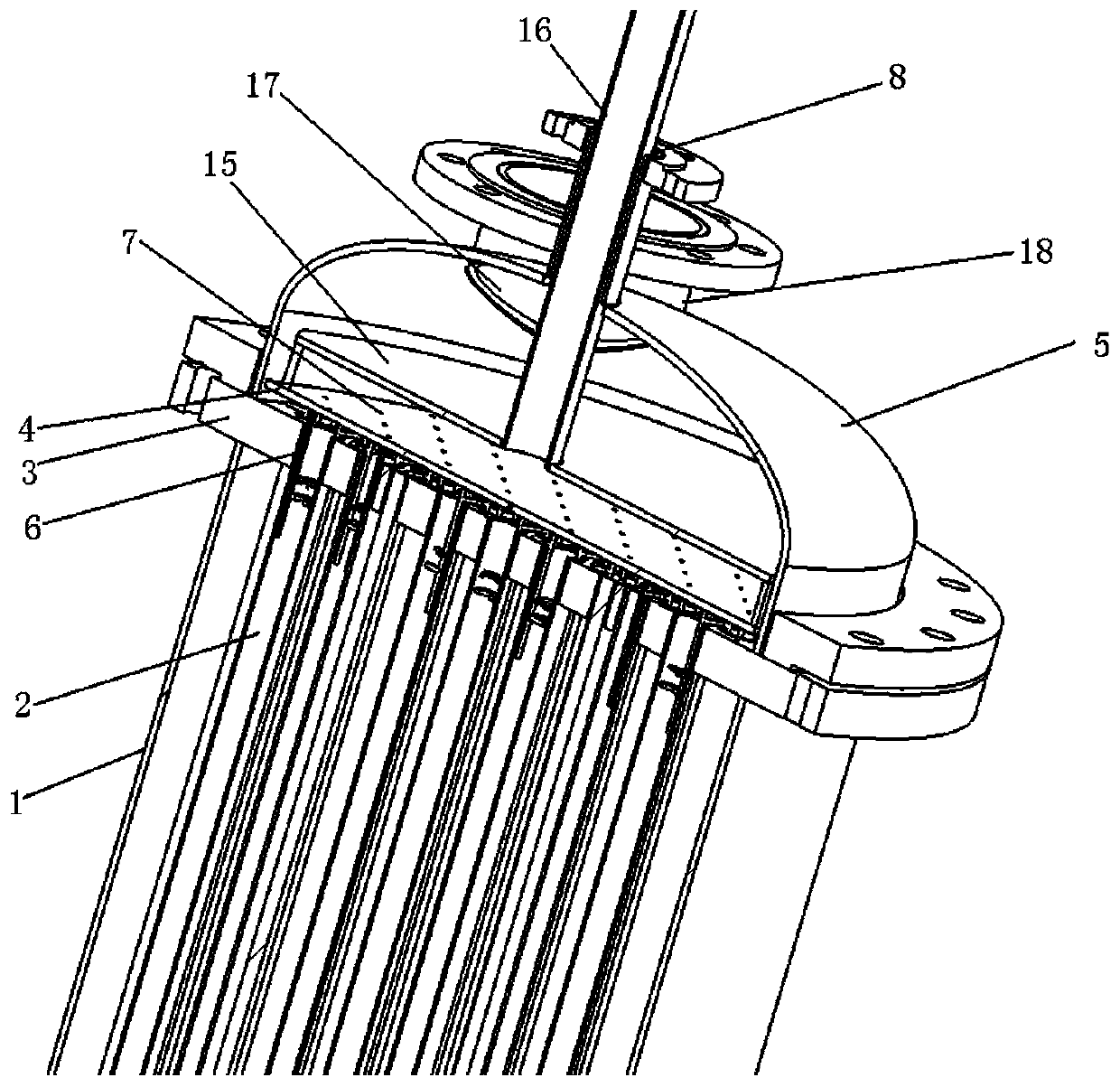

[0030] Combined with the manual Figure 1-2 , the invention discloses a liquid distribution structure of distillation equipment, which is used in the distillation equipment with housing 1 and heat exchange tubes 2, including: a liquid spray chamber and a liquid separation device; wherein the bottom plate of the liquid spray chamber is provided with multiple A porous plate 4 with a liquid separation hole 7, the liquid separation hole 7 is arranged corresponding to the heat exchange tube 2; the top of the liquid spray chamber is provided with a liquid inlet;

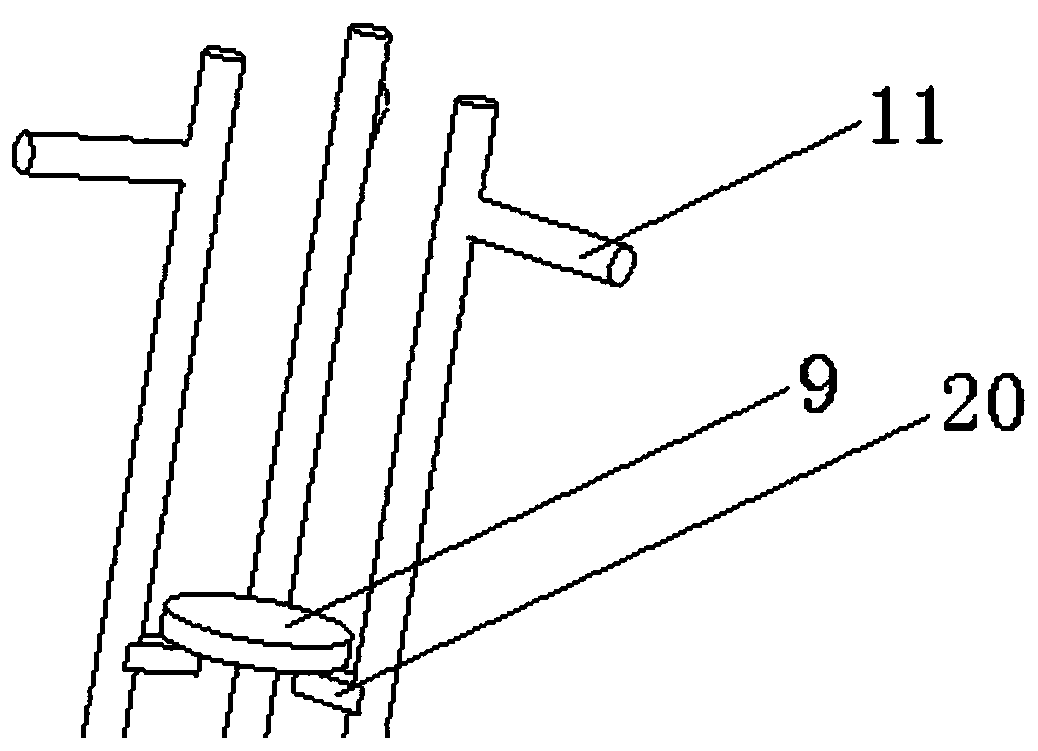

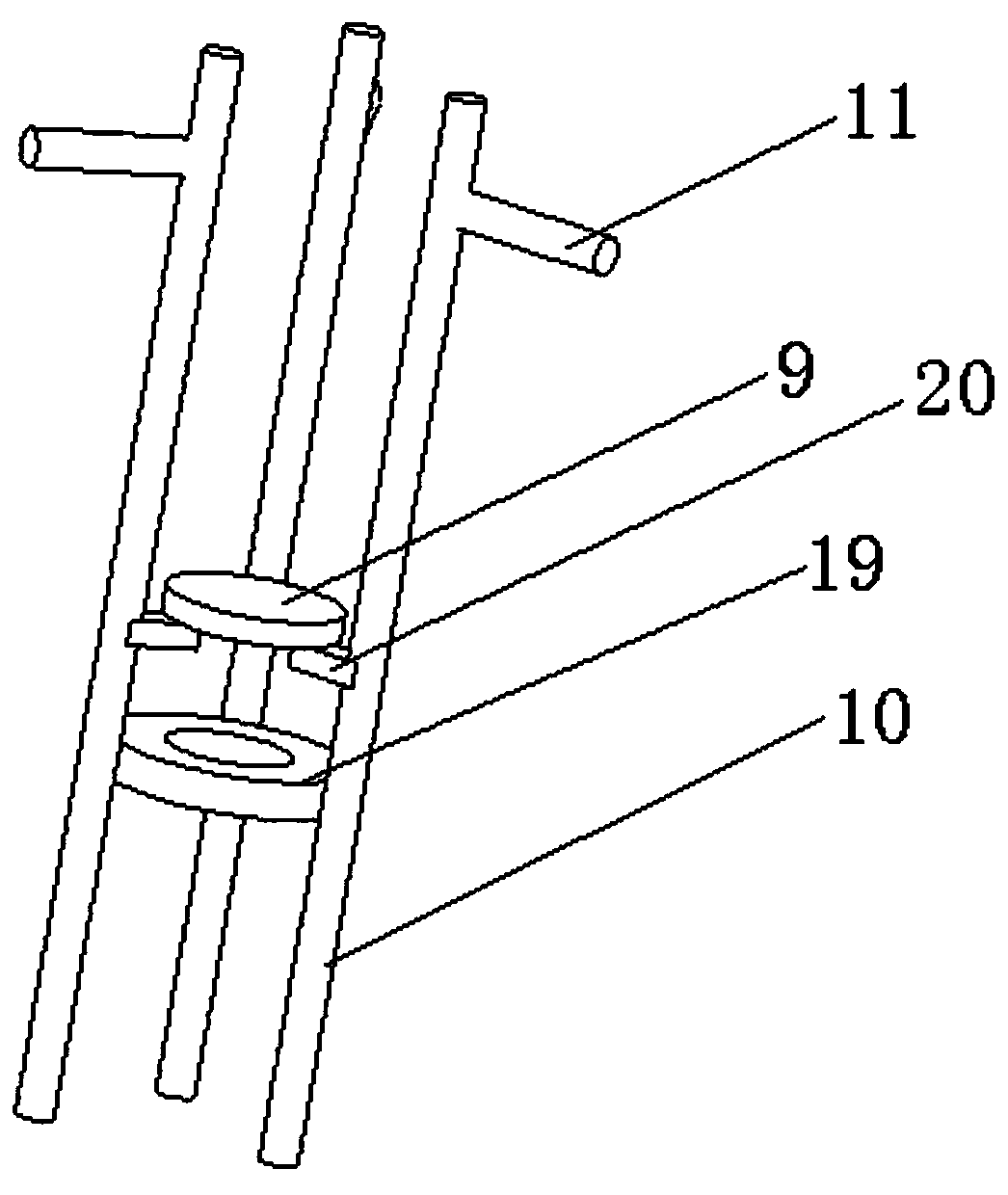

[0031] The liquid separation device includes a liquid separation sheet bracket 10 and a liquid separation sheet 9; the liquid separation sheet 9 is fixed in the heat exchange tube 2 through the liquid separation sheet support 10, and the liquid separation sheet 9 is perpendicular to the axis of the heat exchange tube or the included angle is greater than 45 degrees Set, there is a gap between the edge of the liquid separat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap