Hollow double spirally-wound plastic hose and production process thereof

A technology for plastic hoses and production processes, applied in the field of hoses, can solve problems such as cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

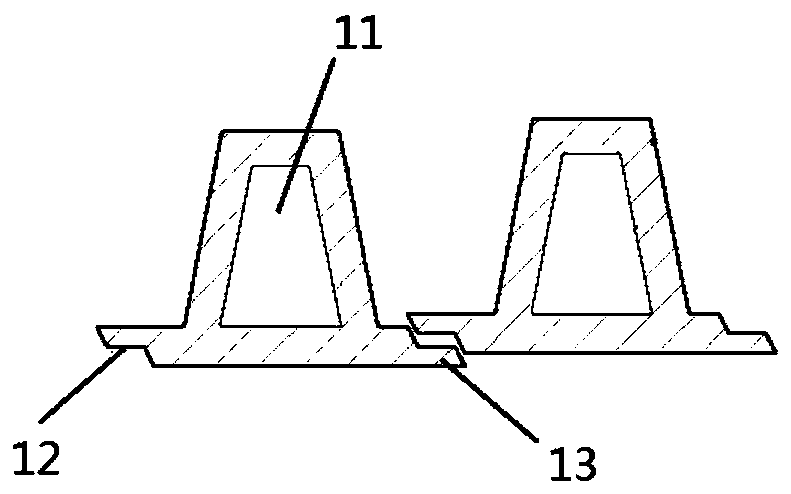

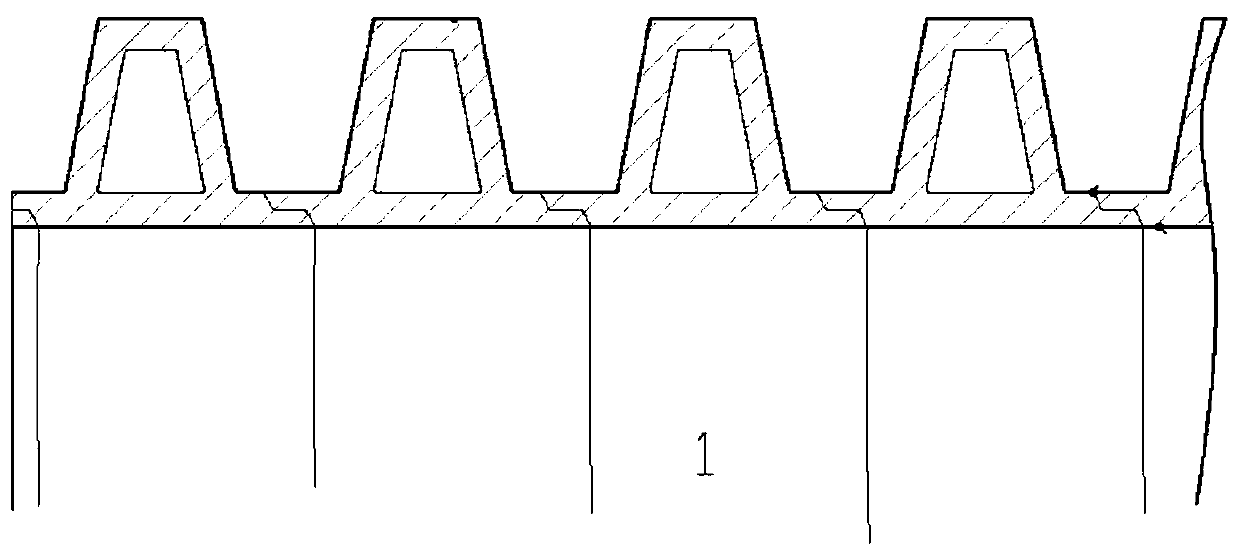

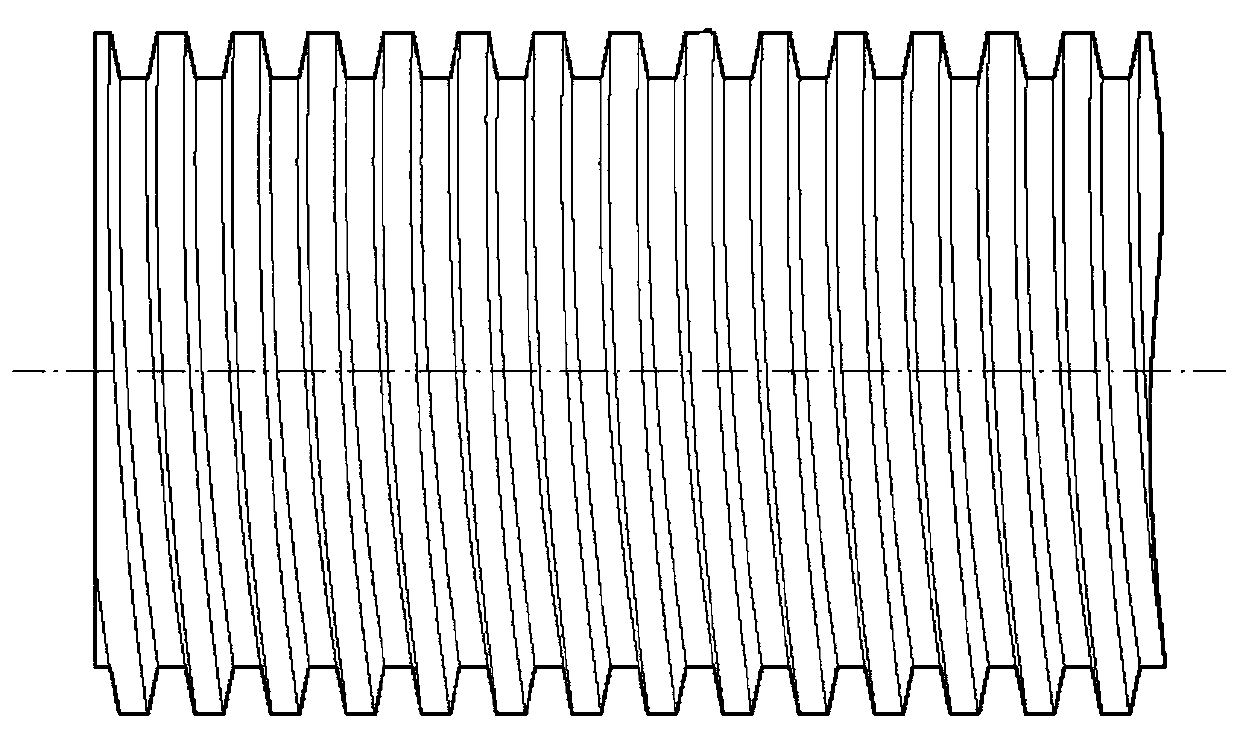

[0036] The invention provides a hollow double-helix wound plastic hose, which is composed of a base strip 1 and a reinforcement strip 2 . Seen from the cross-section, the basic strip 1 is composed of three parts, the middle part is a hollow trapezoidal winding unit 11, the front and rear flanks are connecting edges, and the rear flank 13 is provided with a stepped bonding section, The front side wing 12 is an adhesive section with an inverted step, and is adhesively fitted with the rear adhesive section. The reinforcing strip 2 is an upside-down embedded hollow regular trapezoid a or hollow hexagon b.

[0037] The production process of the hollow double-helix wound plastic hose of the present invention, the specific process steps are as follows:

[0038] First, the base tape 1 is extruded from the first extruder 31, and the base tape 1 is wound. At the same time, the second extruder 32 is used to extrude the reinforced strip 2; wherein, the process of the first extruder 31 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap