Digital three-dimensional part virtual assembly method based on assembly points

A technology of virtual assembly and parts, applied in the field of virtual assembly, can solve the problems of cumbersome control, invisibility of the virtual assembly process, and high technical ability requirements of virtual assemblers, so as to expand the scope of application, strengthen the intuitiveness, and improve the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples will further illustrate the present invention in conjunction with the accompanying drawings.

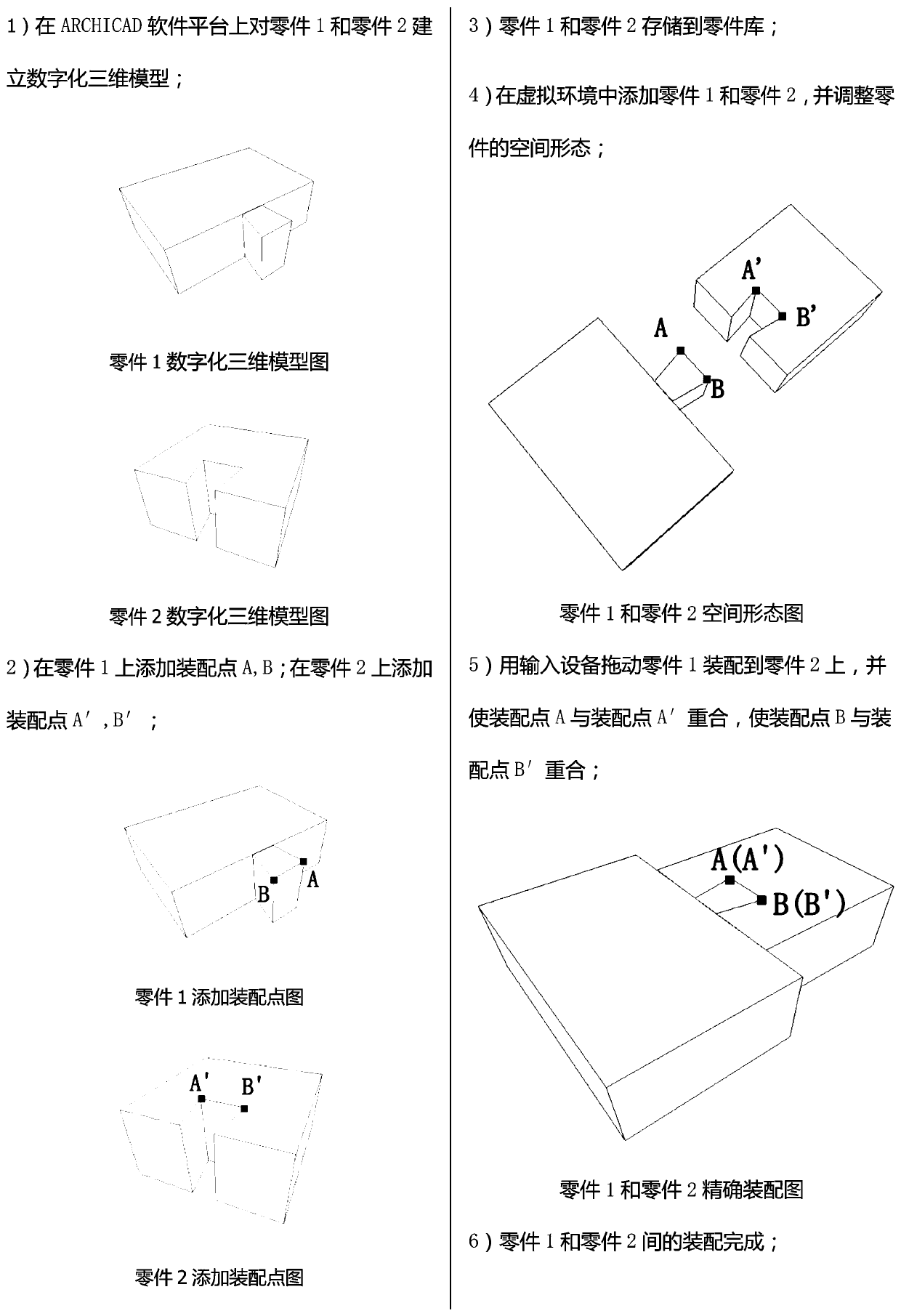

[0022] see figure 2 , a virtual assembly method for digital 3D components based on assembly points:

[0023] 1) Establish a digital three-dimensional model of part 1 and part 2 on the ARCHICAD software platform;

[0024] 2) Add assembly points A and B on part 1; add assembly points A' and B' on part 2;

[0025] 3) Store part 1 and part 2 in the parts library;

[0026] 4) Add part 1 and part 2 in the virtual environment of the computer, and adjust the spatial form of the parts;

[0027] 5) Use the mouse to accurately capture the assembly point A on part 1, use point A as the base point to move part 1 to the vicinity of point A' on part 2, use the mouse to accurately capture the assembly point A' and place part 1, assembly point A It can coincide with the assembly point A', and the assembly point B and the assembly point B' can also coincide;

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com