Artificial tooth body having vertical type bone beam structure

An artificial tooth, upright technology, used in dentistry, dental implants, dental prosthetics, etc., can solve the problems of incomplete bone fusion, unable to withstand occlusal force, low bone fusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

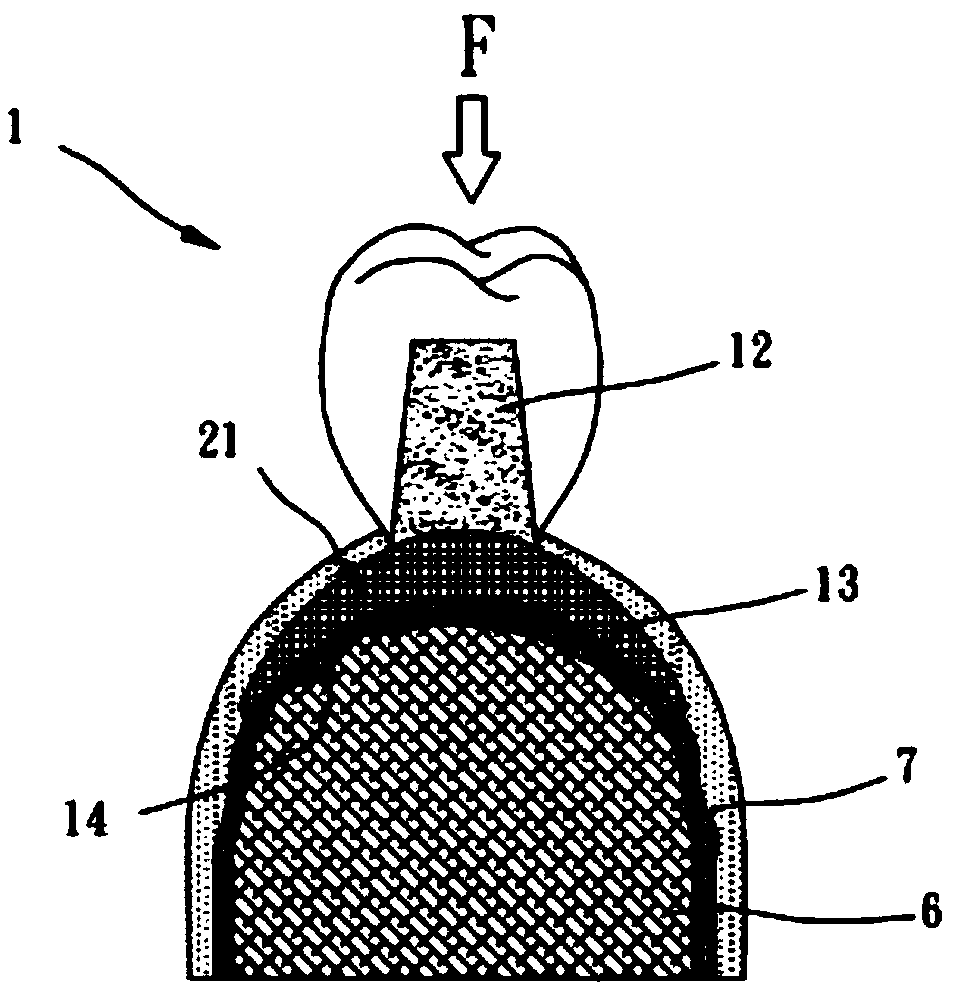

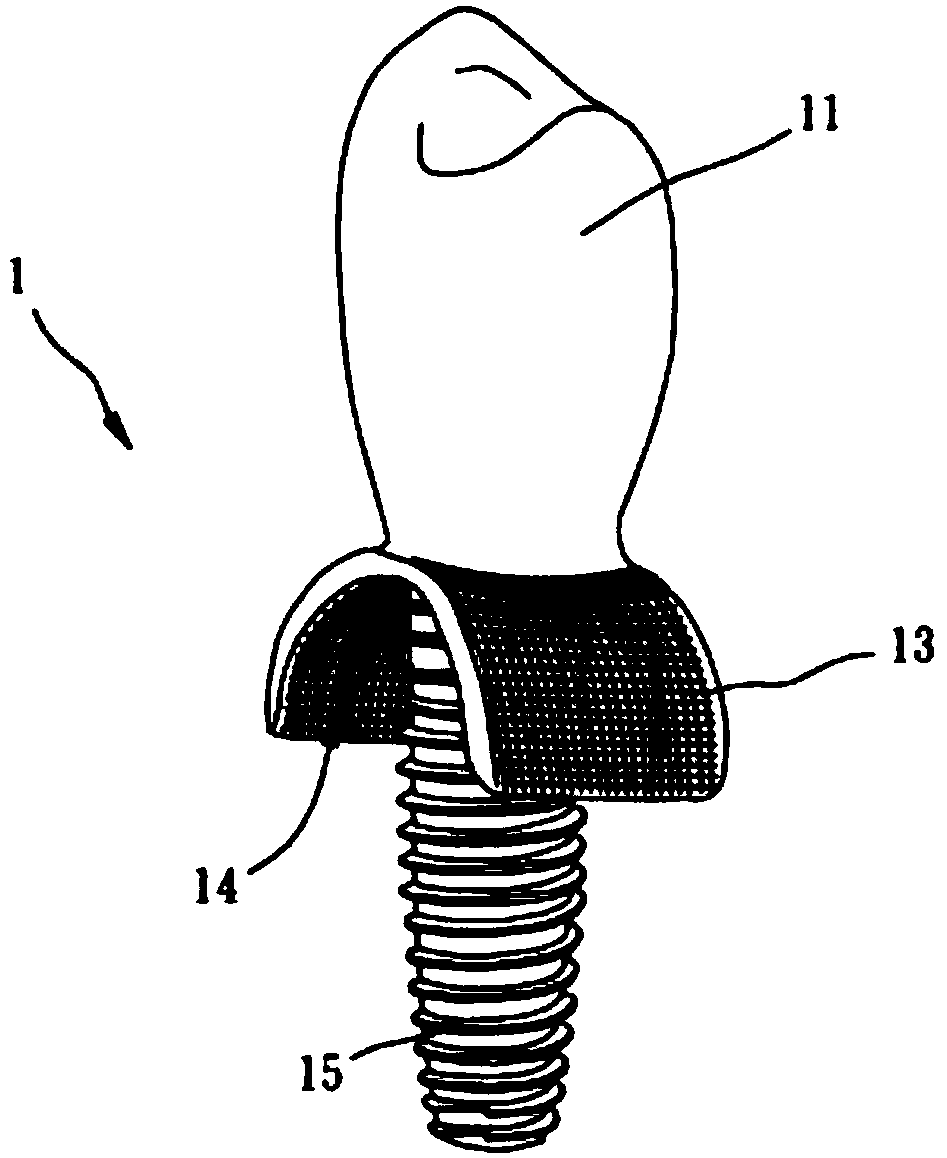

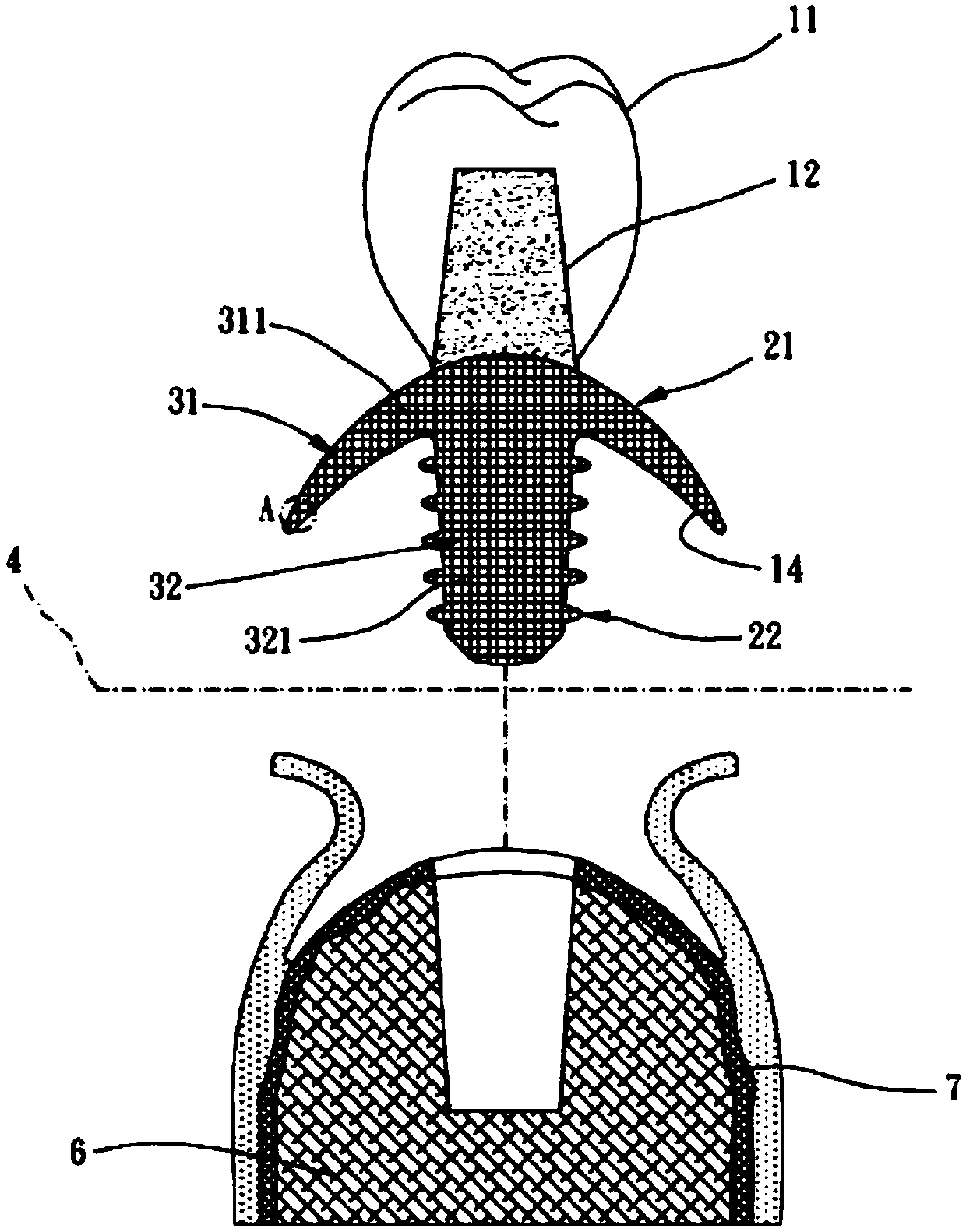

[0039] Please refer to figure 1 , which shows a first embodiment of the present invention, an artificial tooth 1 with a vertical bone beam structure of the present invention, which includes an abutment 12 and an artificial gum 13, the abutment 12 is connected to the artificial tooth 13 An artificial tooth crown 11 is connected to the upper part, and the artificial gum bed 13 is constructed by a plurality of first bone beams 21 . Define the occlusal force direction towards the alveolar bone 6 as a reference direction 5, and define a virtual plane 4 for being located above the alveolar bone 6, and the extension direction of the reference direction 5 is perpendicular to the virtual plane 4 (please refer to image 3 shown); each of the first bone beams 21 includes an upright support column 211 extending along the reference direction 5 and perpendicular to the virtual plane 4, wherein each of the first bone beams 21 further includes a plurality of strengthening beams 212 , the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com