Novel automobile mold

An automobile mold, a new type of technology, applied in the direction of forming tools, manufacturing tools, cleaning methods and utensils, etc., can solve the problems of consuming a lot of manpower and financial resources, affecting the stability of parts, and many processes, achieving easy cleaning, convenient connection, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

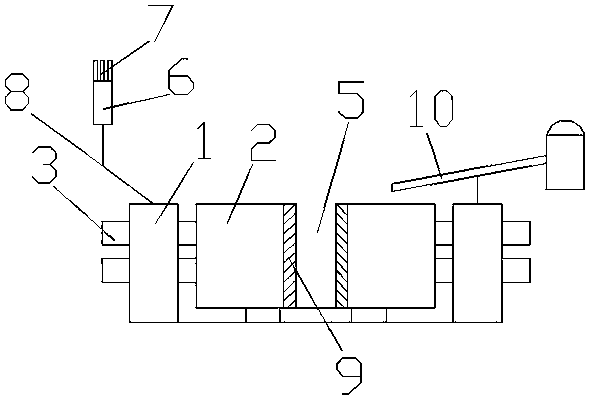

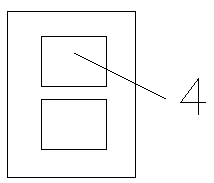

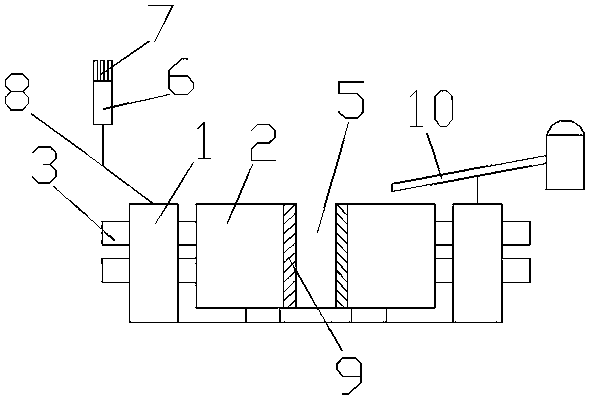

[0013] A new type of automobile mould, which is provided with an outer mold 1 and an inner mold 2, an inner mold 2 is arranged on the inner side of the outer mold 1, a connecting device 3 is arranged between the outer mold 1 and the inner mold 2, and the outer wall of the inner mold 2 is arranged There is a connecting groove 4, a stamping chamber 5 is arranged inside the inner mold 2, and a cleaning device 6 is arranged beside the stamping chamber 5.

[0014] The connecting device 3 is a connecting rod, and the connecting rod passes through the outer mold and is connected into the connecting groove 4 on the outer wall of the inner mold 2 .

[0015] The cleaning device 6 is provided with a cleaning brush 7 , and a traction rope 8 is arranged under the cleaning brush 7 .

[0016] The traction rope 8 is a flexible rubber traction rope, and the traction rope 8 is fixed on the outside of the cleaning device.

Embodiment 2

[0018] A new type of automobile mould, which is provided with an outer mold 1 and an inner mold 2, an inner mold 2 is arranged on the inner side of the outer mold 1, a connecting device 3 is arranged between the outer mold 1 and the inner mold 2, and the outer wall of the inner mold 2 is arranged There is a connecting groove 4, a stamping chamber 5 is arranged inside the inner mold 2, and a cleaning device 6 is arranged beside the stamping chamber 5.

[0019] The connecting device 3 is a connecting rod, and the connecting rod passes through the outer mold and is connected into the connecting groove 4 on the outer wall of the inner mold 2 .

[0020] The cleaning device 6 is provided with a cleaning brush 7 , and a traction rope 8 is arranged under the cleaning brush 7 .

[0021] The traction rope 8 is a flexible rubber traction rope, and the traction rope 8 is fixed on the outside of the cleaning device.

[0022] Stamping plates 9 are arranged on both sides of the stamping cha...

Embodiment 3

[0024] A new type of automobile mould, which is provided with an outer mold 1 and an inner mold 2, an inner mold 2 is arranged on the inner side of the outer mold 1, a connecting device 3 is arranged between the outer mold 1 and the inner mold 2, and the outer wall of the inner mold 2 is arranged There is a connecting groove 4, a stamping chamber 5 is arranged inside the inner mold 2, and a cleaning device 6 is arranged beside the stamping chamber 5.

[0025] The connecting device 3 is a connecting rod, and the connecting rod passes through the outer mold and is connected into the connecting groove 4 on the outer wall of the inner mold 2 .

[0026] The cleaning device 6 is provided with a cleaning brush 7 , and a traction rope 8 is arranged under the cleaning brush 7 .

[0027] The traction rope 8 is a flexible rubber traction rope, and the traction rope 8 is fixed on the outside of the cleaning device.

[0028] Stamping plates 9 are arranged on both sides of the stamping cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com