Size-adjustable sucker set

A technology of size and suction cup, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of slow production cycle, repeated disassembly and replacement time, and inability to realize common handling structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

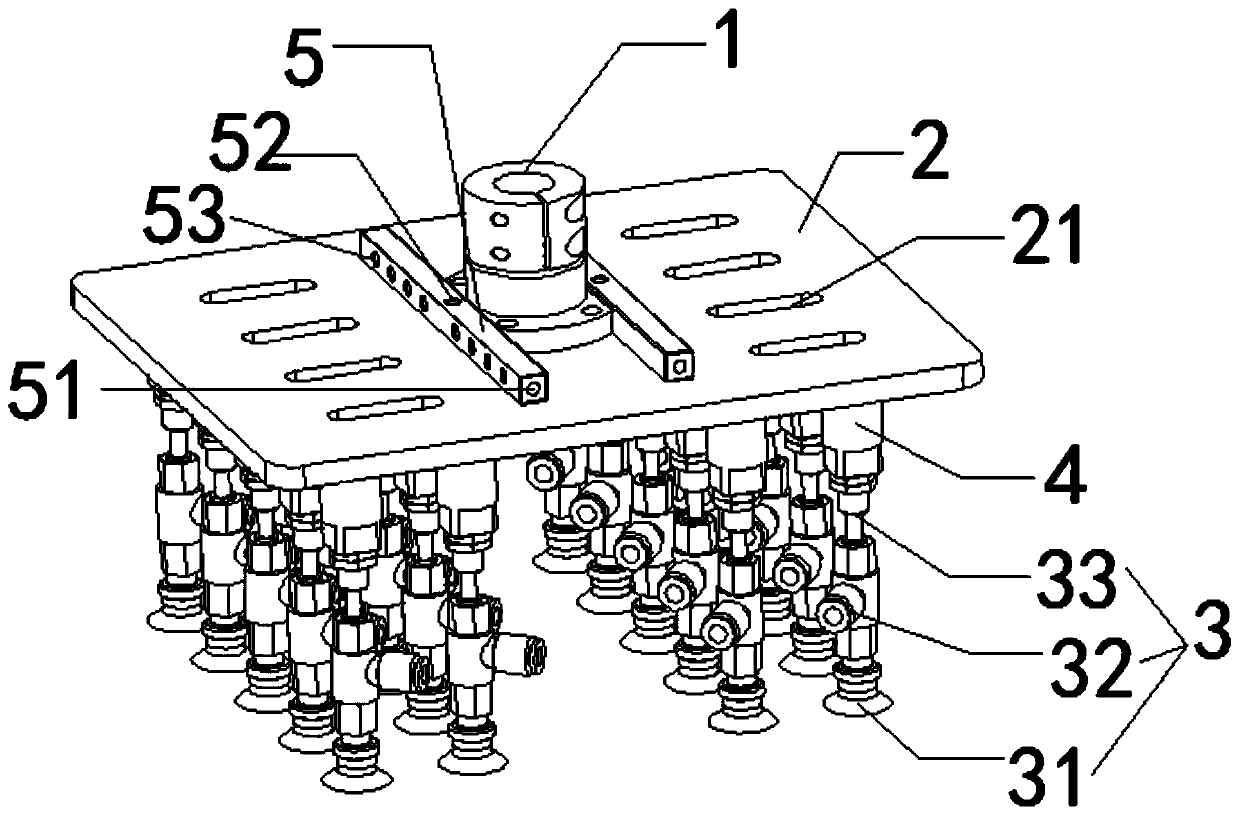

[0029] A size-adjustable suction cup set, comprising: a clamping fixed seat 1 for fixing a mechanical arm, a connecting plate 2, a vacuum suction cup assembly 3, a magnetic adsorption assembly 4, the base of the clamping fixed seat 1 and the connecting plate 2 The board surface is fixed by screws, and the vacuum chuck assembly 3 is fixed on the lower end surface of the connection board 2 through the magnetic adsorption assembly 4 .

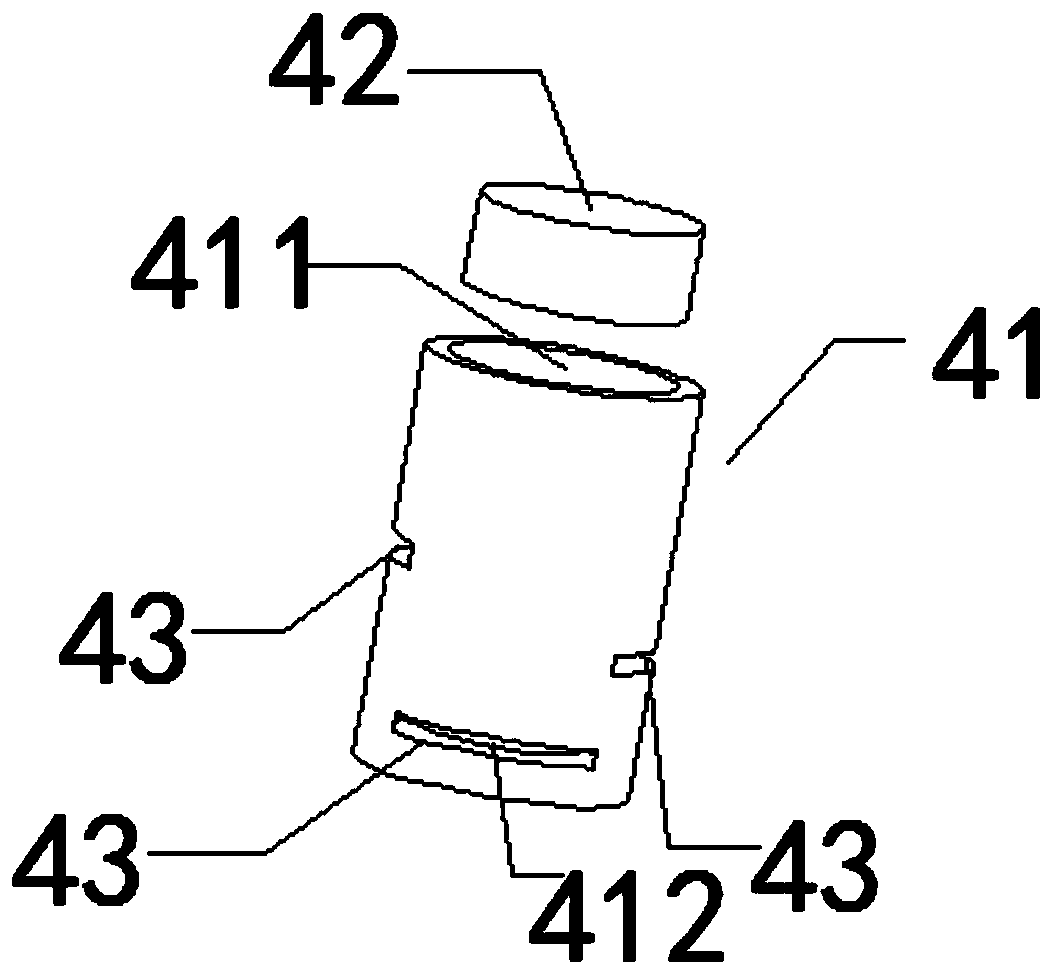

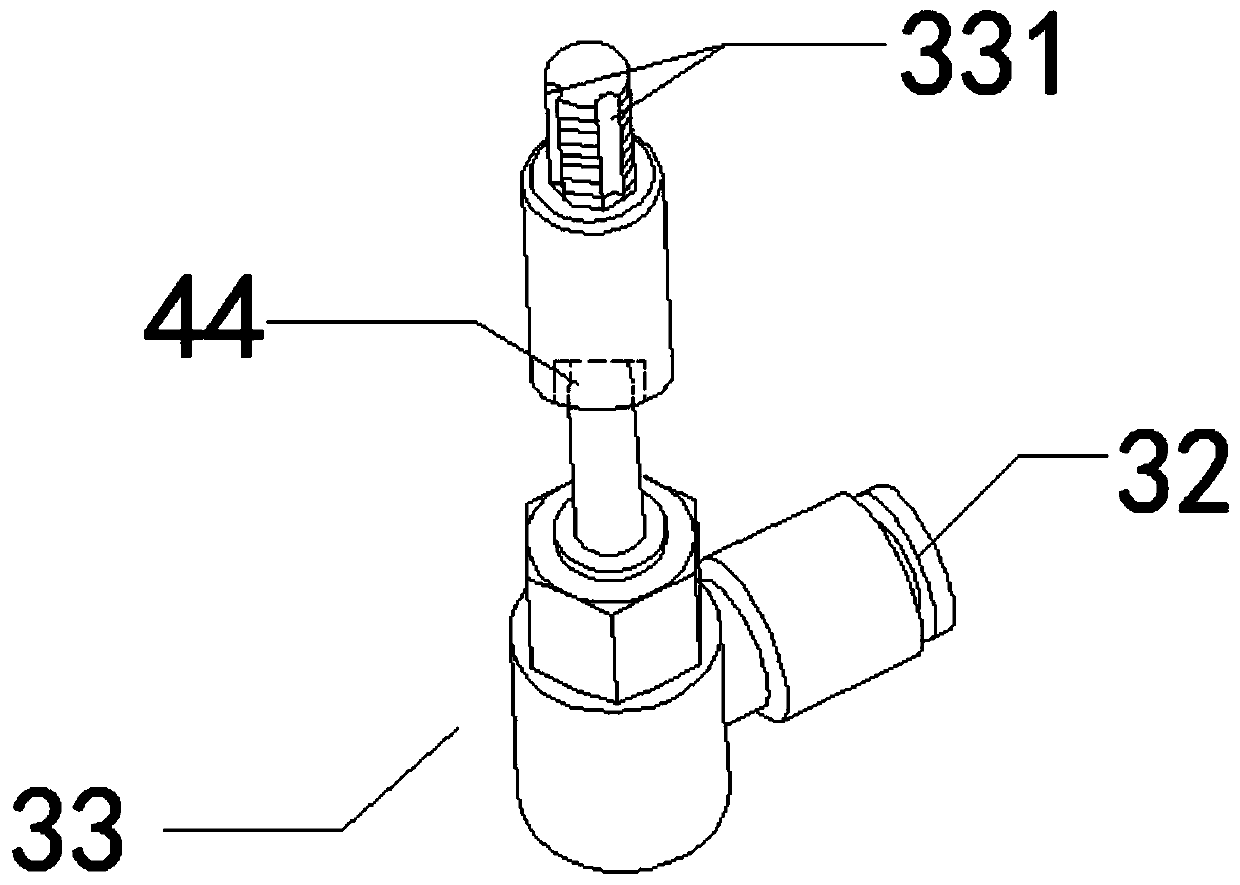

[0030] Wherein, the magnetic adsorption assembly 4 includes a fixed post 41 and a magnetic sheet 42. The upper end of the fixed post 41 is processed with a magnetic sheet accommodating groove 411, and the lower end is processed with a threaded blind hole 412. The magnetic sheet 42 is fixed in the magnetic sheet accommodating groove 411. The vacuum chuck assembly 3 includes a vacuum nozzle 31, an air valve 32, and an air nozzle fixed shaft 33 processed with a central ventilation blind hole, wherein the vacuum suction nozzle 31 is fixed on the lower ...

specific Embodiment example 2

[0035] A size-adjustable suction cup set, comprising: a clamping fixed seat 1 for fixing a mechanical arm, a connecting plate 2, a vacuum suction cup assembly 3, a magnetic adsorption assembly 4, the base of the clamping fixed seat 1 and the connecting plate 2 The board surface is fixed by screws, and the vacuum chuck assembly 3 is fixed on the lower end surface of the connection board 2 through the magnetic adsorption assembly 4 . Wherein, the magnetic adsorption assembly 4 includes a fixed post 41 and a magnetic sheet 42. The upper end of the fixed post 41 is processed with a magnetic sheet accommodating groove 411, and the lower end is processed with a threaded blind hole 412. The magnetic sheet 42 is fixed in the magnetic sheet accommodating groove 411. The vacuum chuck assembly 3 includes a vacuum nozzle 31, an air valve 32, and an air nozzle fixed shaft 33 processed with a central ventilation blind hole, wherein the vacuum suction nozzle 31 is fixed on the lower end of th...

specific Embodiment example 3

[0039] A size-adjustable suction cup set, comprising: a clamping fixed seat 1 for fixing a mechanical arm, a connecting plate 2, a vacuum suction cup assembly 3, a magnetic adsorption assembly 4, the base of the clamping fixed seat 1 and the connecting plate 2 The board surface is fixed by screws, and the vacuum chuck assembly 3 is fixed on the lower end surface of the connection board 2 through the magnetic adsorption assembly 4 . Wherein, the magnetic adsorption assembly 4 includes a fixed post 41 and a magnetic sheet 42. The upper end of the fixed post 41 is processed with a magnetic sheet accommodating groove 411, and the lower end is processed with a threaded blind hole 412. The magnetic sheet 42 is fixed in the magnetic sheet accommodating groove 411. The vacuum chuck assembly 3 includes a vacuum nozzle 31, an air valve 32, and an air nozzle fixed shaft 33 processed with a central ventilation blind hole, wherein the vacuum suction nozzle 31 is fixed on the lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com