A low-temperature gravity heat pipe using carbon dioxide as a working medium and its filling method

A technology of carbon dioxide and gravity heat pipes, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems that the advantages of low-temperature heat transfer have not been brought into play, the safety requirements of high-pressure equipment are high, and the sealing requirements of filling equipment are high. , to achieve good environmental friendliness, superior performance, simple and easy production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

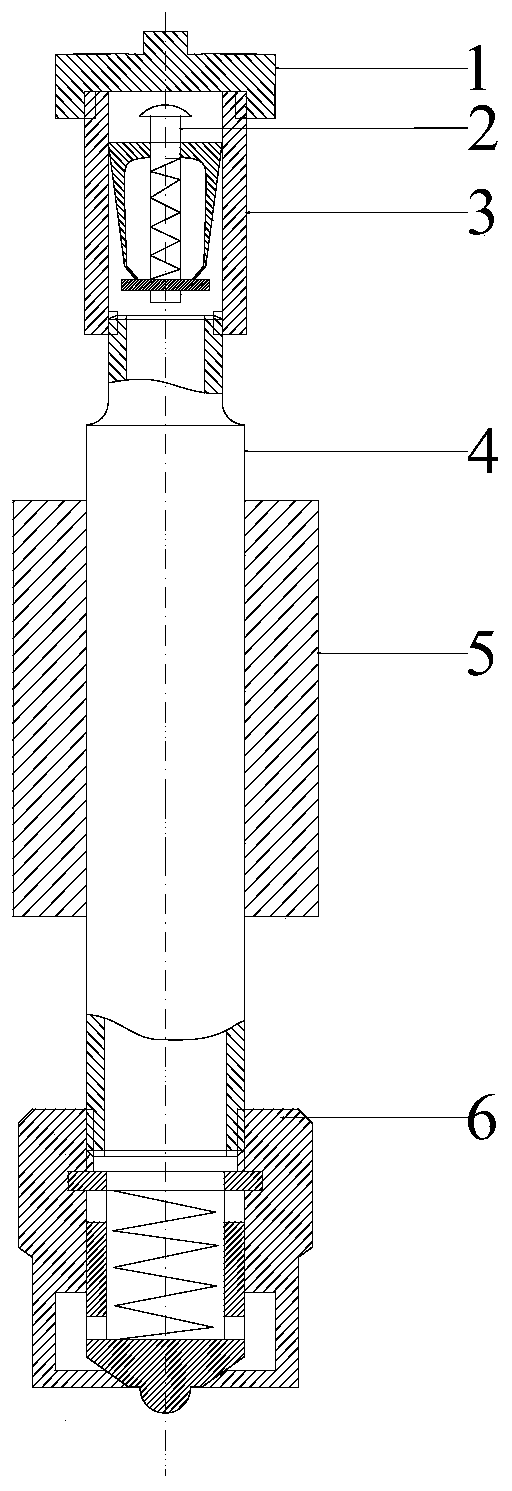

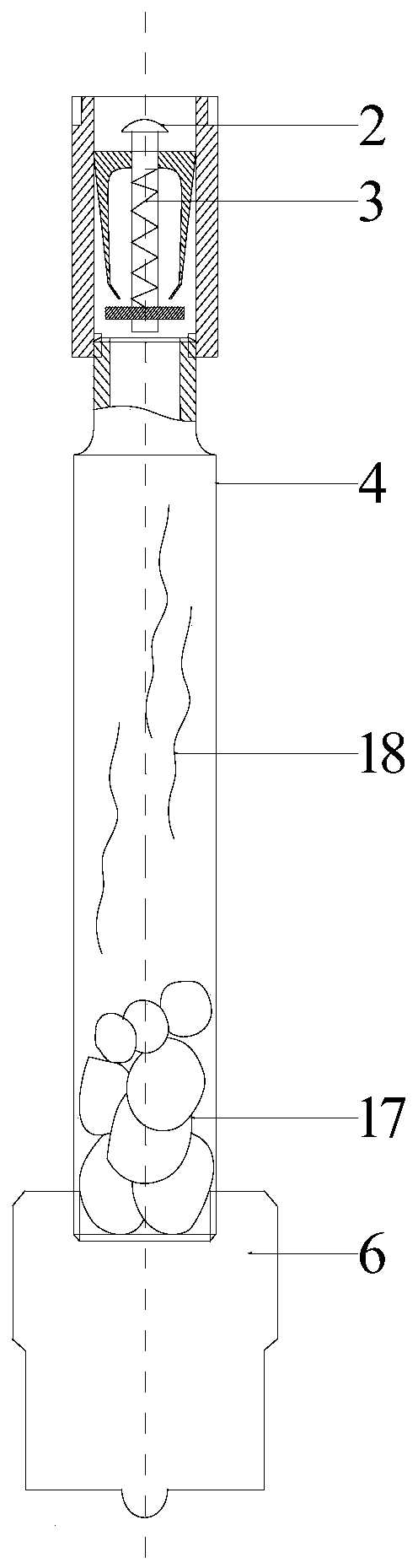

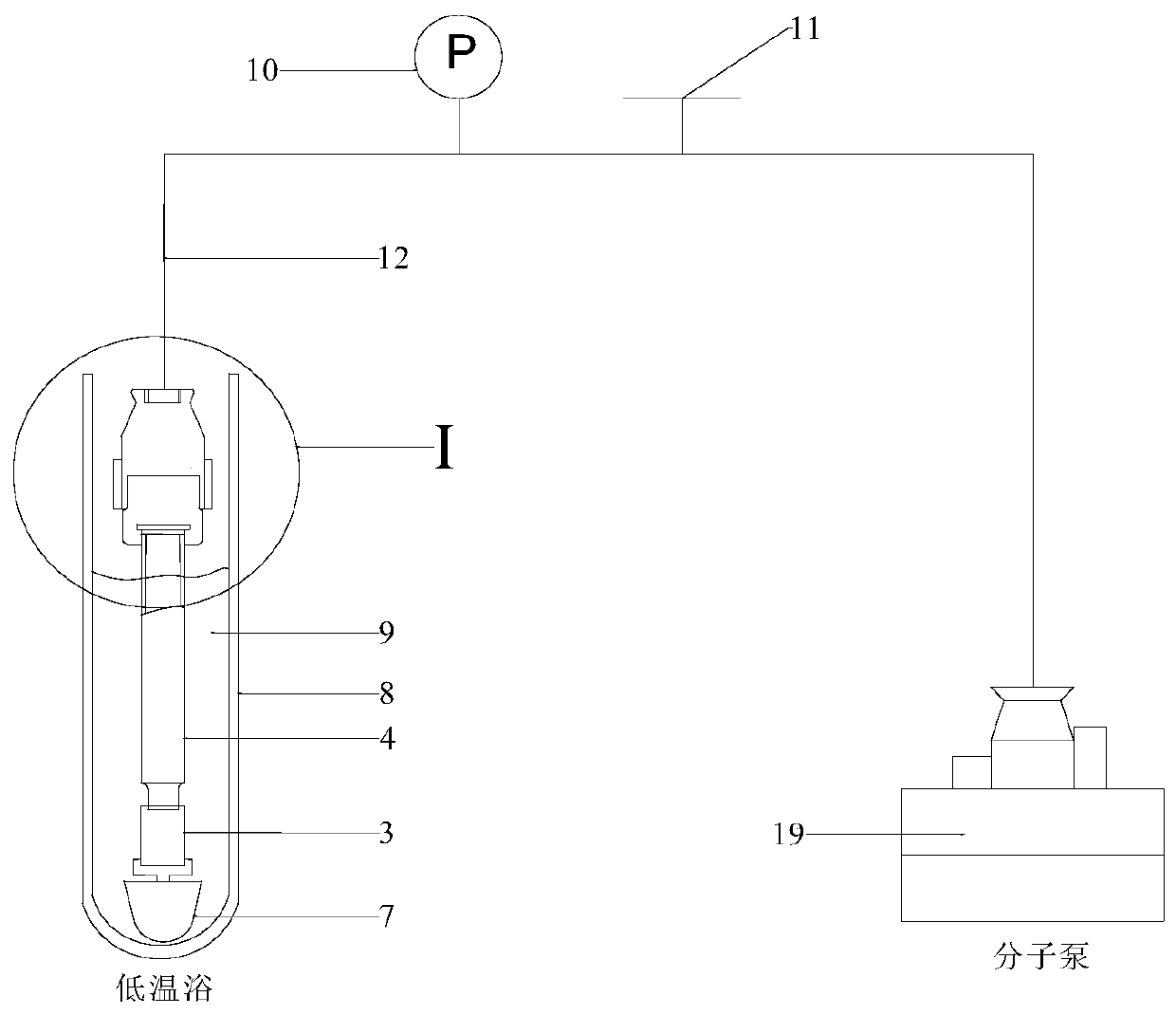

[0032]A low-temperature gravity heat pipe using carbon dioxide as a working medium of the present invention is mainly composed of a one-way needle valve 3, a pipe body 4 filled with dry ice 17, heat-insulating cotton 5, and a fast-installed one-way valve male head 6; The one-way needle valve 3 and the fast-installed one-way valve male head 6 are one-way flow parts, and the fluid can only flow in along the inlet, and cannot flow out; one end of the pipe body 4 is connected to the one-way needle valve 3, and the other end is connected to the fast The one-way valve male head 6 is installed, and the heat insulation cotton 5 is set on the outer wall of the pipe body 4; the one-way needle valve 3 is welded and fixedly connected with the pipe body 4, and the quick-installed one-way valve male head 6 It is threadedly connected with the pipe body 4, and the on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com