Glass bonding primers containing aldimines

A technology of dialdimine and primer, applied in adhesive types, polyurea/polyurethane adhesives, adhesives, etc., which can solve problems such as loss of crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0018] The invention is further illustrated by the following non-limiting examples.

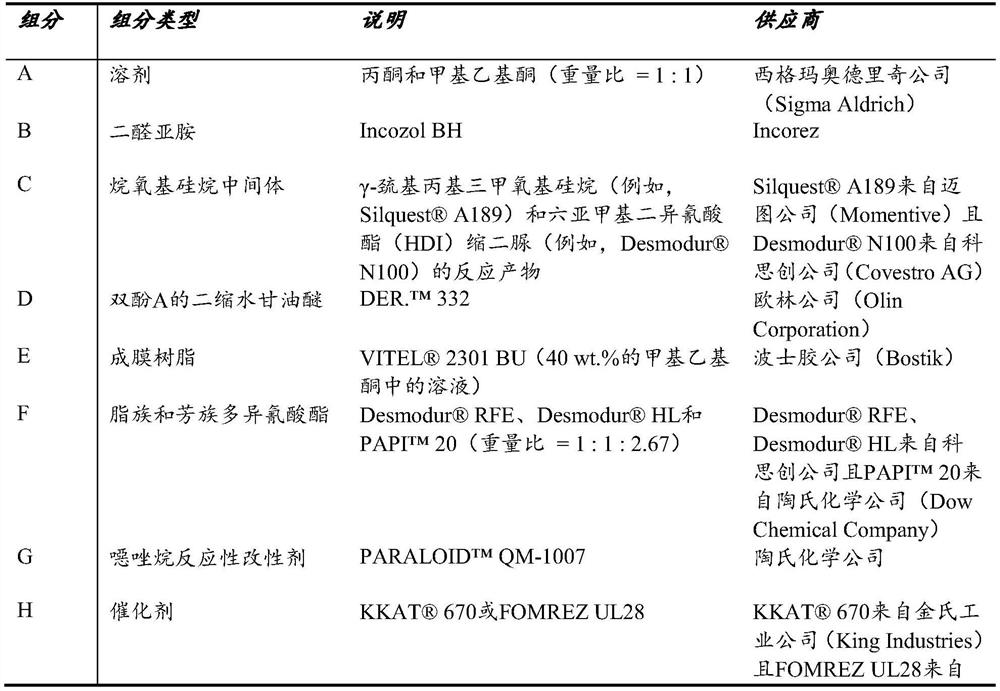

[0019] Table 1 shows the various feedstock components and their sources used in the preparation of the Examples illustrating the invention.

[0020] Components used in the present invention in table 1

[0021]

[0022]

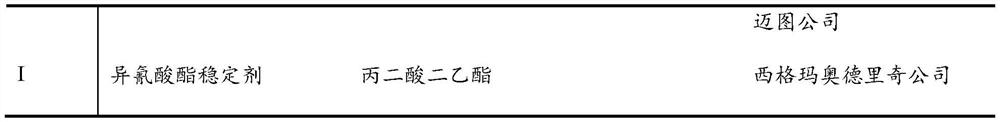

[0023] Table 2 summarizes various examples prepared to illustrate the invention. Examples 1 to 6 are samples according to the invention which contain aldimine, whereas examples 7 to 10 are comparative samples which do not contain aldimine.

[0024] Table 2 Contents of each example prepared.

[0025]

[0026] 1 Use Fomrez UL28 available from Momentive

[0027] 2 Using the KKAT 670 available from King's Industries

[0028] Additionally, two commercial black primers were used as comparative examples. The first primer, Example 11, is a commercial two-step glass bonding primer called BETASEAL TM 43520A, which is commercially available from The Dow Chemical Compan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com