Multi-functional manipulator

A multi-functional manipulator and mechanical claw technology, applied in the field of machinery, can solve the problem of single function of the manipulator, and achieve the effect of eliminating manual oiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

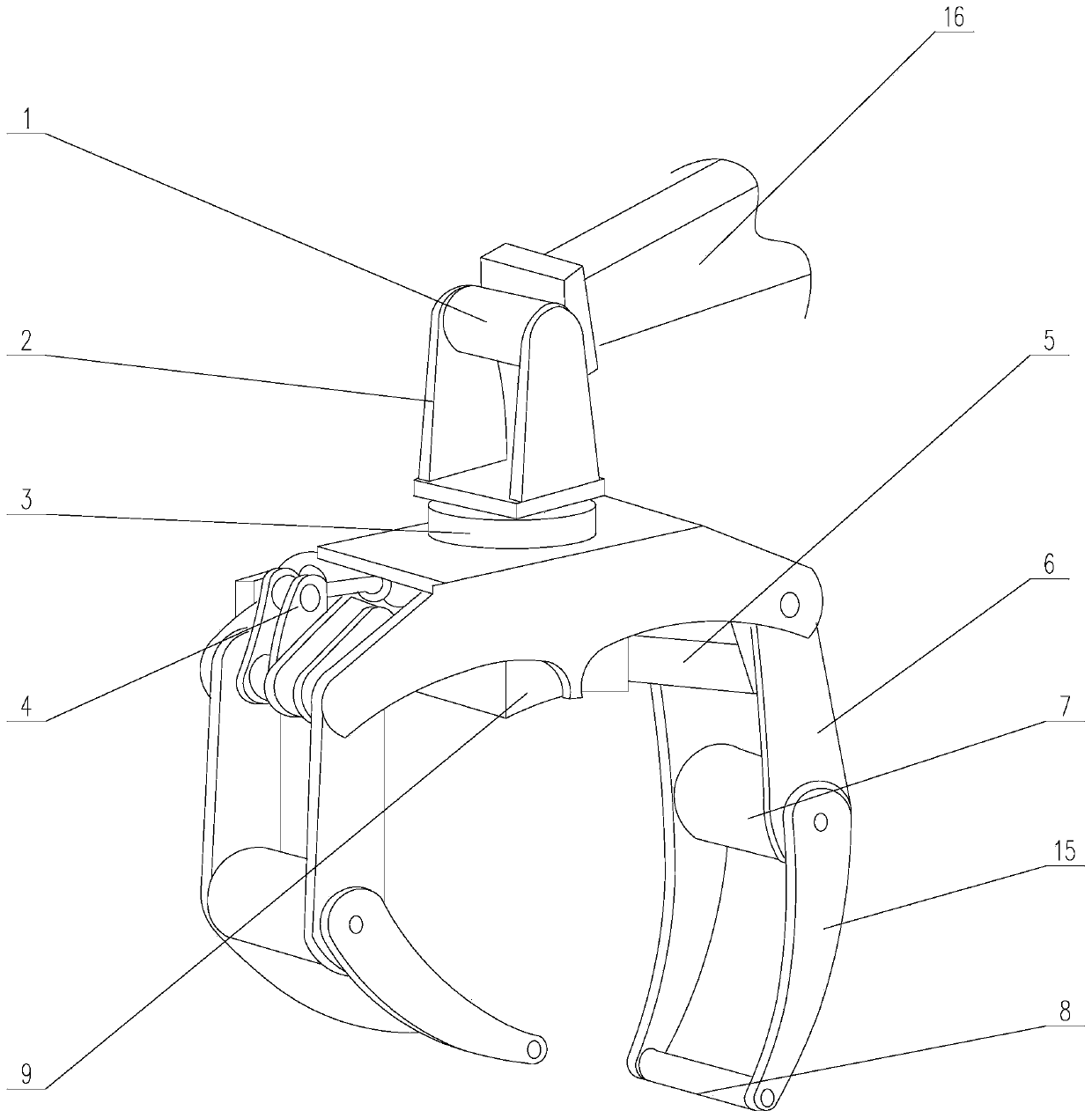

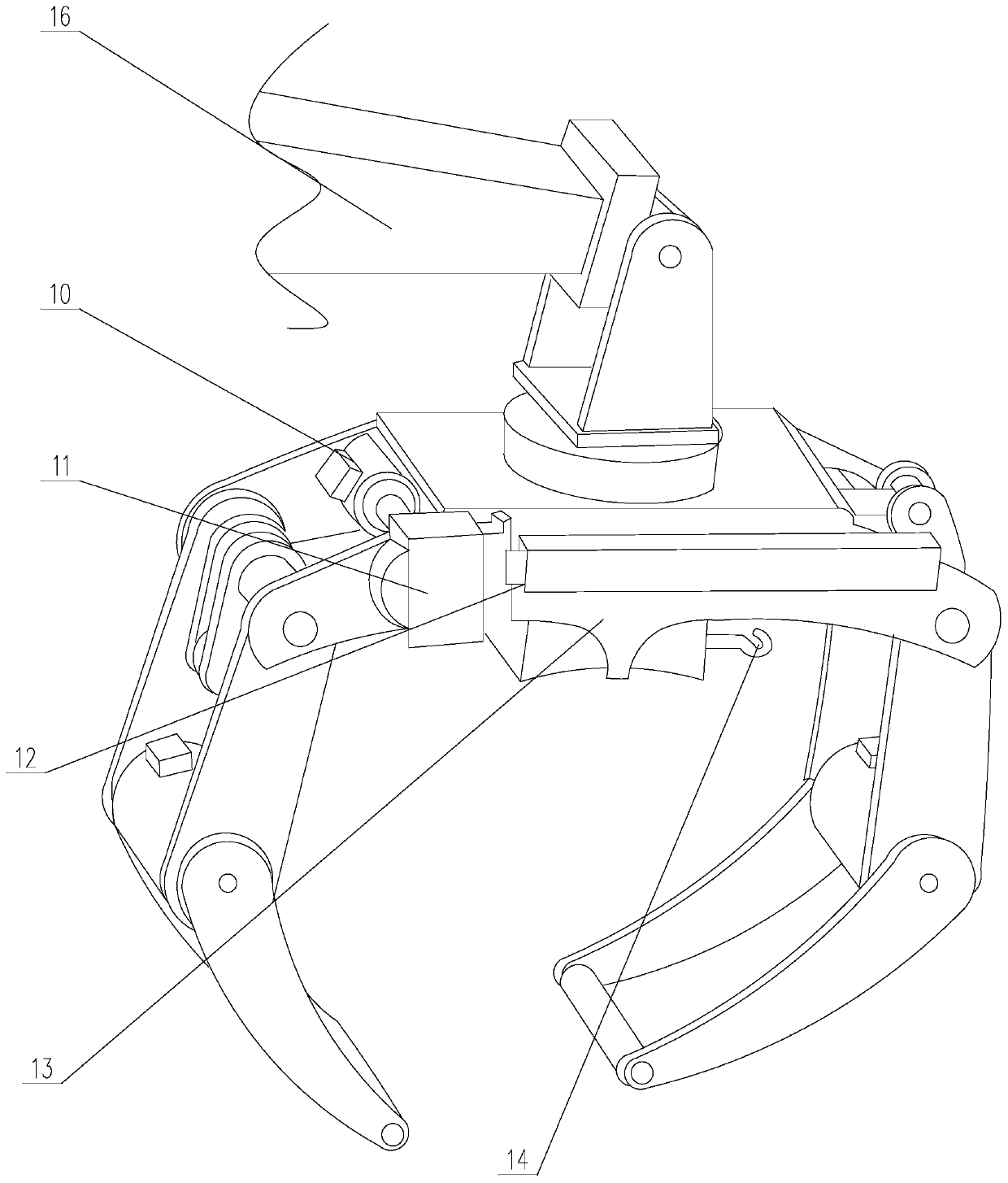

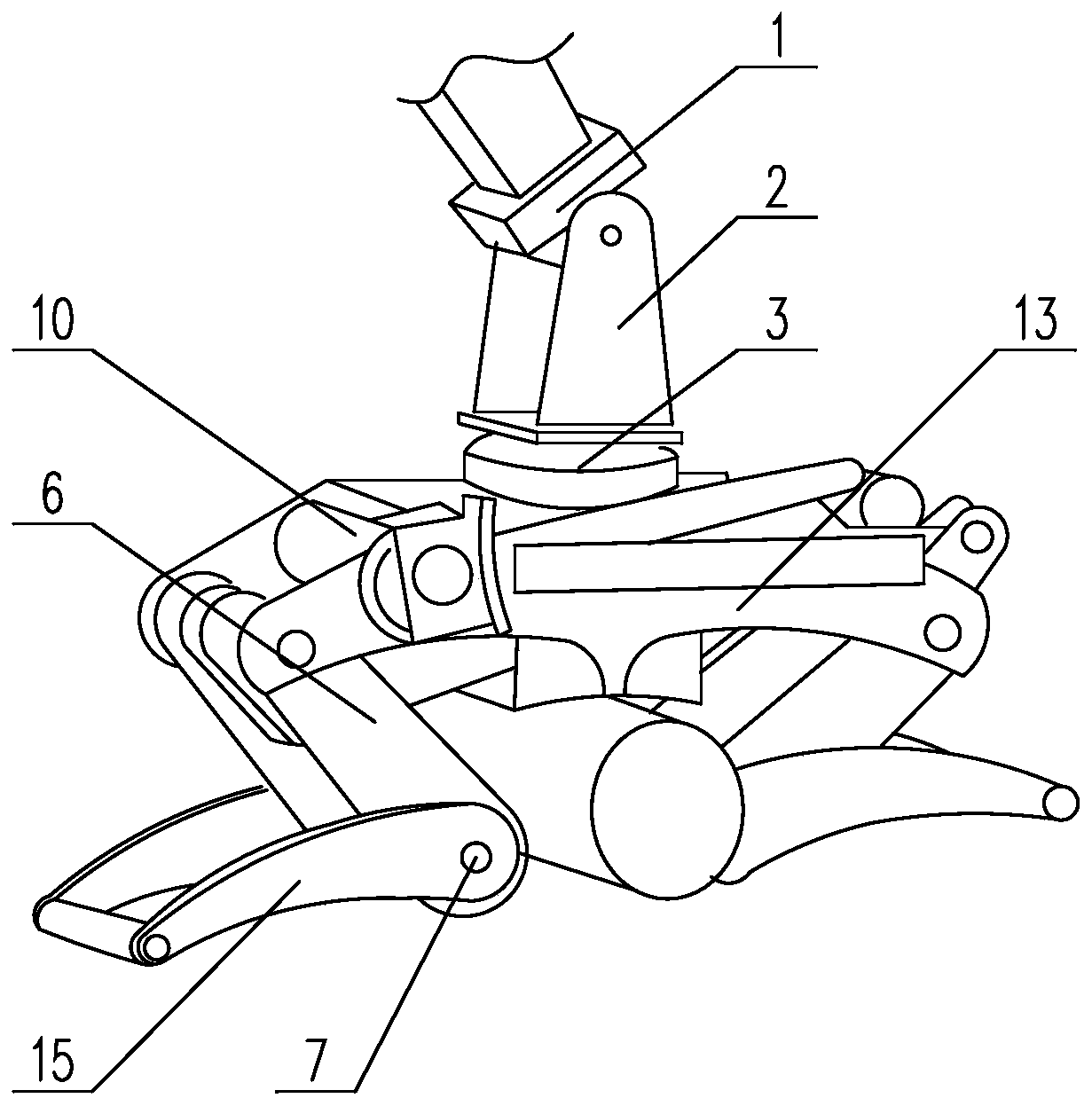

[0039] A multifunctional manipulator, comprising a folding arm 16, a rotary joint 1, an upper support 2, a rotary joint 3, a lower frame 13, a clamping oil cylinder 4, a clamping synchronous link mechanism 5, mechanical claws, a chain saw 12, and a chain Saw mount 11;

[0040] One end of the folding arm 16 is connected to the upper support 2 through the rotary joint 1, the upper support 2 is connected to the lower frame 13 through the rotary joint 3, the clamping cylinder 4 is installed on the lower frame 13, and the clamping cylinder 4 Cooperating with mechanical claws, the chain saw joint 10 is installed on the side of the lower frame 13, the chain saw 12 is connected with the chain saw joint 10 through the chain saw mounting seat 11, and a lifting hook 14 is arranged on the side of the lower frame 13 close to the ground ;

[0041] There are two mechanical claws, and the two mechanical claws are installed on the left and right ends of the lower frame 13 respectively. One me...

Embodiment 2

[0045] Such as Figure 4 As shown, the operator turns the chain saw 12 to the opposite side of the spare tire close to the side of the bin to ensure that the chain saw 12 will not collide with the side of the bin when the spare tire is grasped. Combining actions of the chain saw joint 10 , the rotary joint 1 and the rotary joint 3 further expands the working space range of the chain saw and improves its cutting capacity to meet the operating requirements in different environments.

Embodiment 3

[0047] Such as image 3As shown, the operator can combine various clamping operation modes by manipulating the rotary joint 1, the rotary joint 3, the finger joint 7 and the clamping cylinder 4, etc., to realize the clamping operation of trees and the like. According to the limitation of space size, the maximum diameter of the multi-functional manipulator holding clamp is 1500mm, and the minimum diameter is 25mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com