Robot power cable guiding device and system thereof

A power cable and guiding device technology, which is applied in the direction of manipulators, manufacturing tools, etc., can solve the problems that the cables are not easy to move freely, difficult to turn, etc., and achieve the effect of reducing surface scratches, reducing friction, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

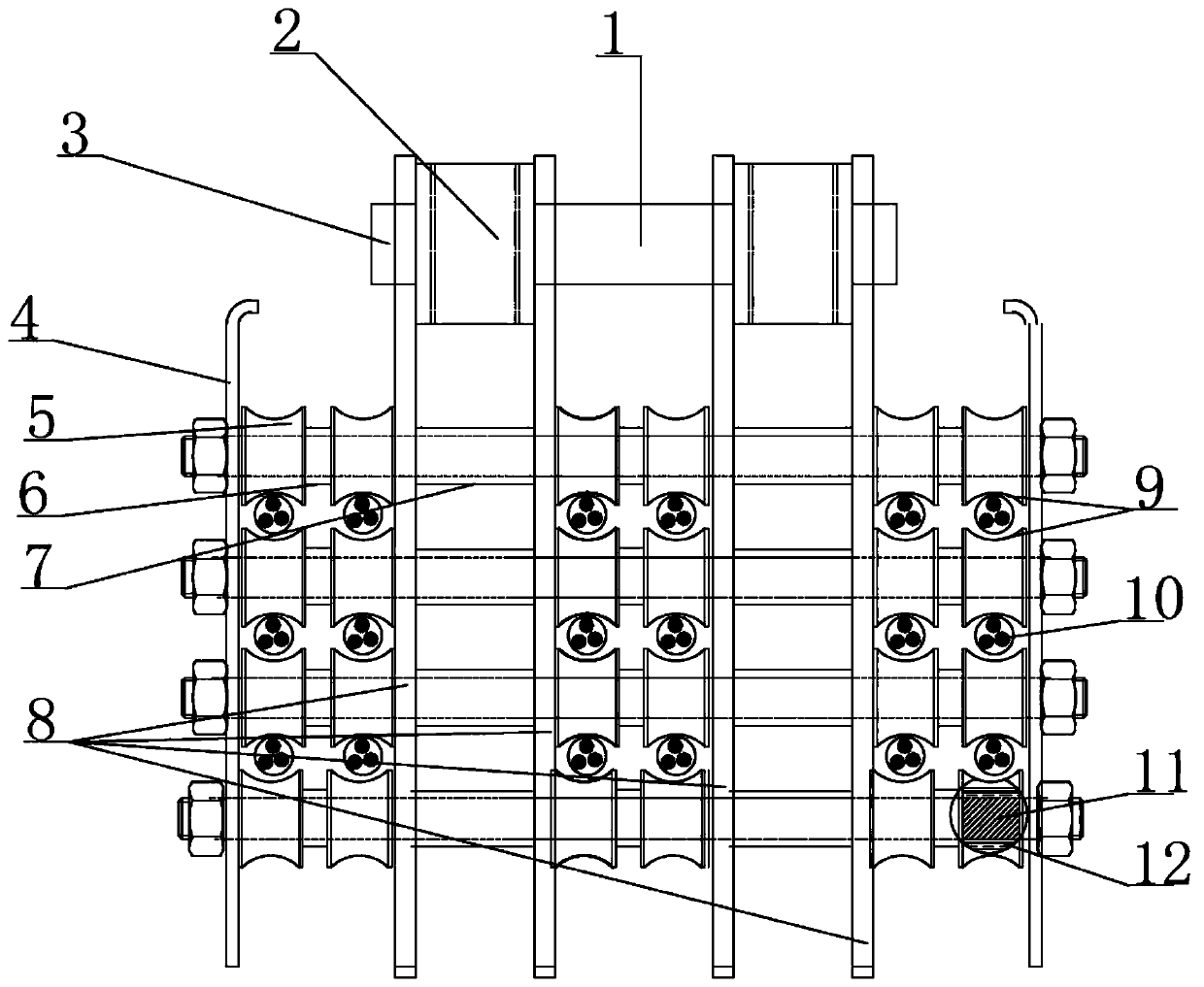

[0039] Implementation case 1: A guiding device for a robot power cable 10, including a body, the body includes four symmetrically arranged substrates 8, a first through hole is arranged on the upper side of the substrate 8, and a first rotating shaft 1 is arranged in the first through hole. The first rotating shaft 1 is provided with a first roller 3, the lower side of the base plate 8 is provided with a second through hole, and a second rotating shaft 11 is arranged in the second through hole, and a plurality of bearings 12 are arranged on the second rotating shaft 11, and the bearings 12 are put on A second roller 5 is provided.

[0040] Such as Figure 4 As shown, the second roller 5 is provided with an arc-shaped groove 9, and an arc-shaped surface is arranged in the arc-shaped groove 9. The arc-shaped design surface of the arc-shaped groove 9 is a good contact surface for cables, and is suitable for When the cable slides on the second roller 5, a grease hole 13 is provid...

Embodiment example 2

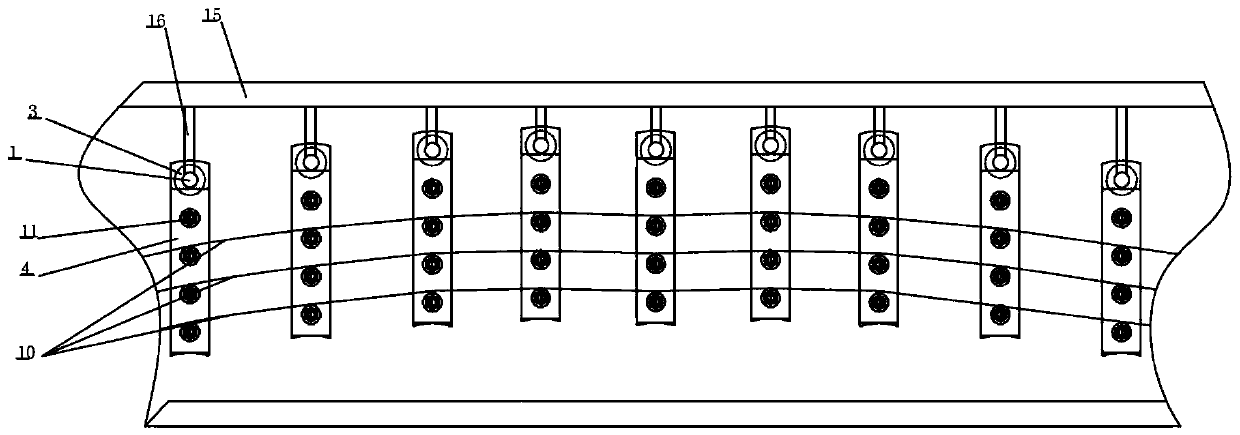

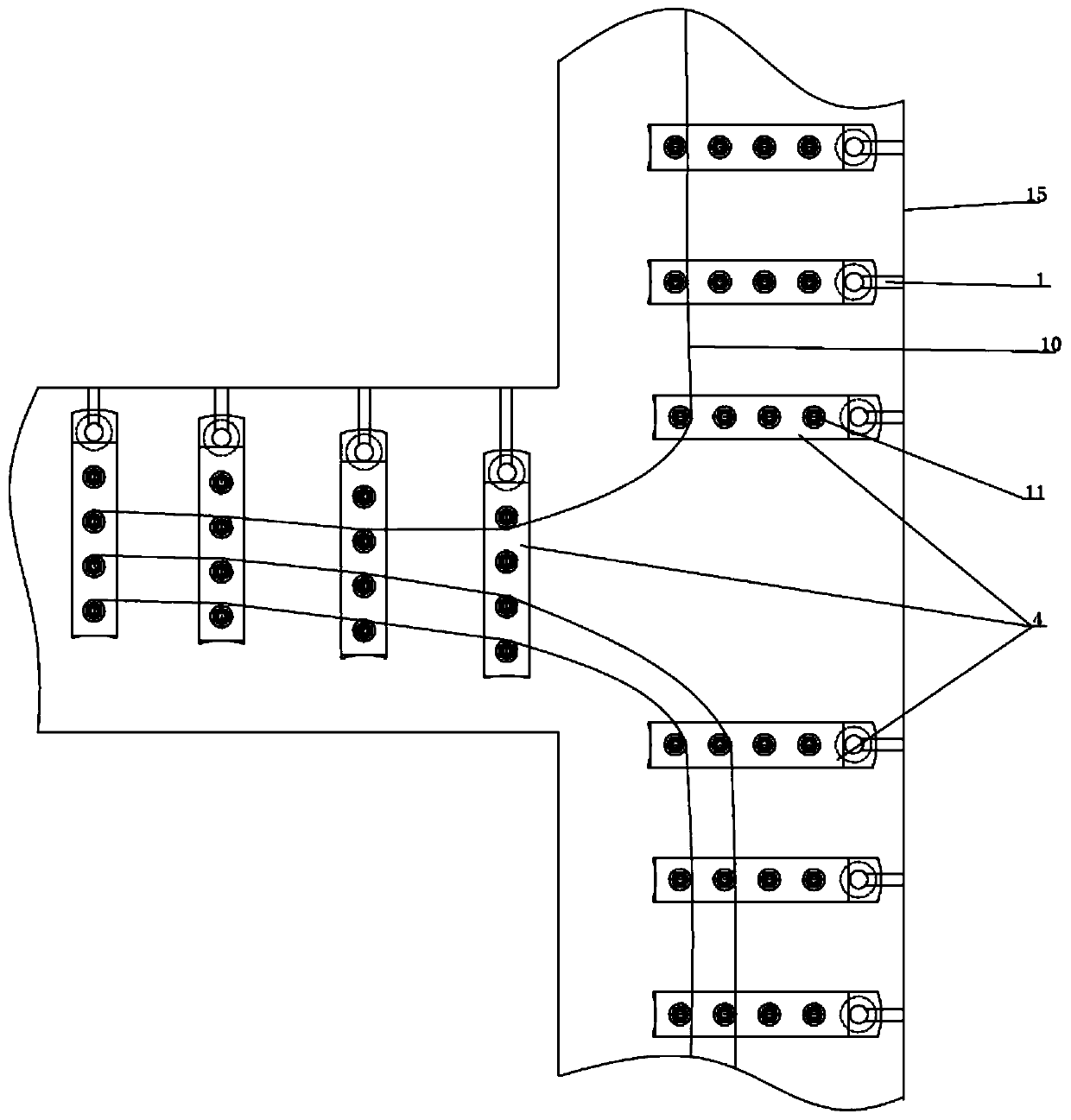

[0044] Implementation Case 2: If figure 1 , figure 2 and image 3 As shown, a robot power cable 10 guiding system includes a pipeline 15 and a power cable 10. The power cable 10 is arranged in the pipeline 15, and a plurality of guiding devices are arranged on the lower side of the pipeline 15. The guiding device includes a body, and the body includes Four symmetrically arranged substrates 8, the upper side of the substrate 8 is provided with a first through hole, the first through hole is provided with a first rotating shaft 1, the first rotating shaft 1 is provided with a first roller 3, and the lower side of the substrate 8 is provided with a first Two through holes, a second rotating shaft 11 is arranged in the second through hole, a plurality of bearings 12 are arranged on the second rotating shaft 11, and a second roller 5 is set on the bearing 12, and the cable passes through the second roller 5 adjacent up and down .

[0045] The size of the first roller 3 is large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com