A Tool Arbor Tailstock Clamped by Taper Set

A tool holder and tailstock technology, applied in the direction of tailstock/top, accessories of toolholders, turning equipment, etc., can solve problems such as inability to meet requirements, and achieve the effect of improving accuracy and rigidity, and improving accuracy and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

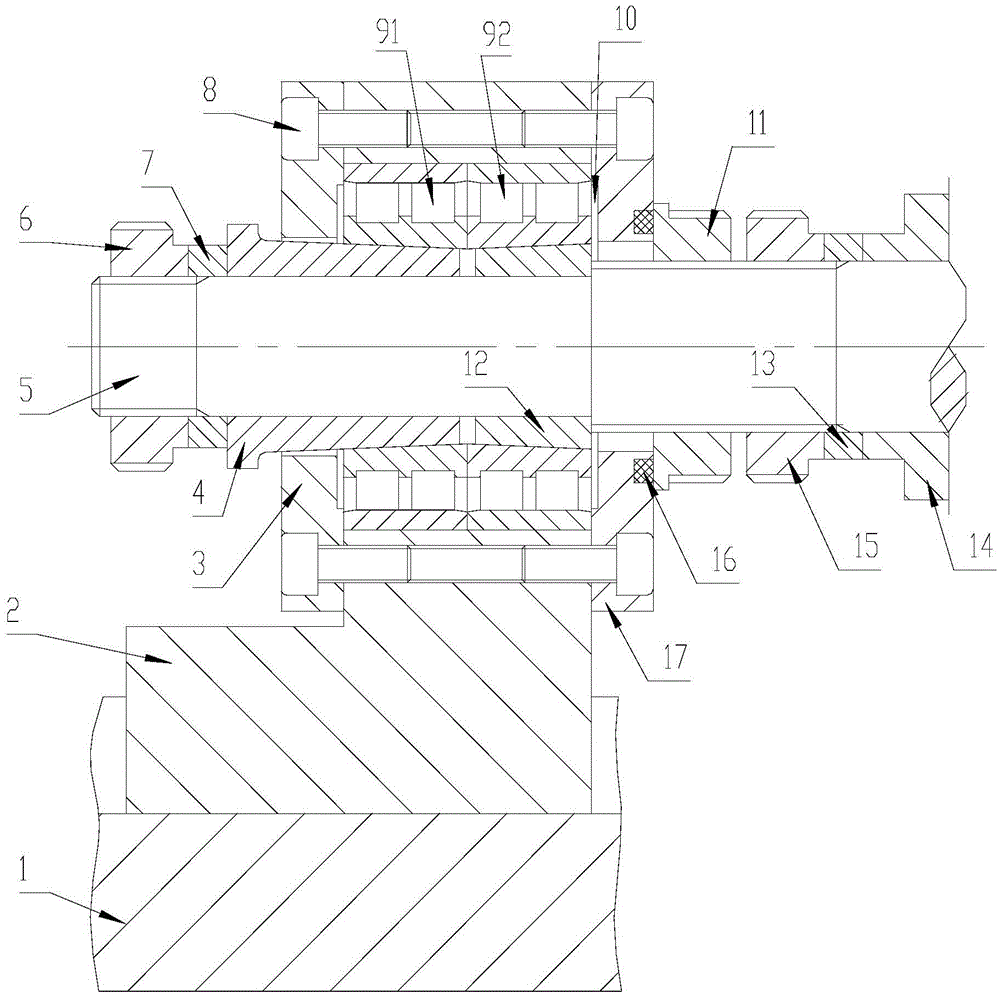

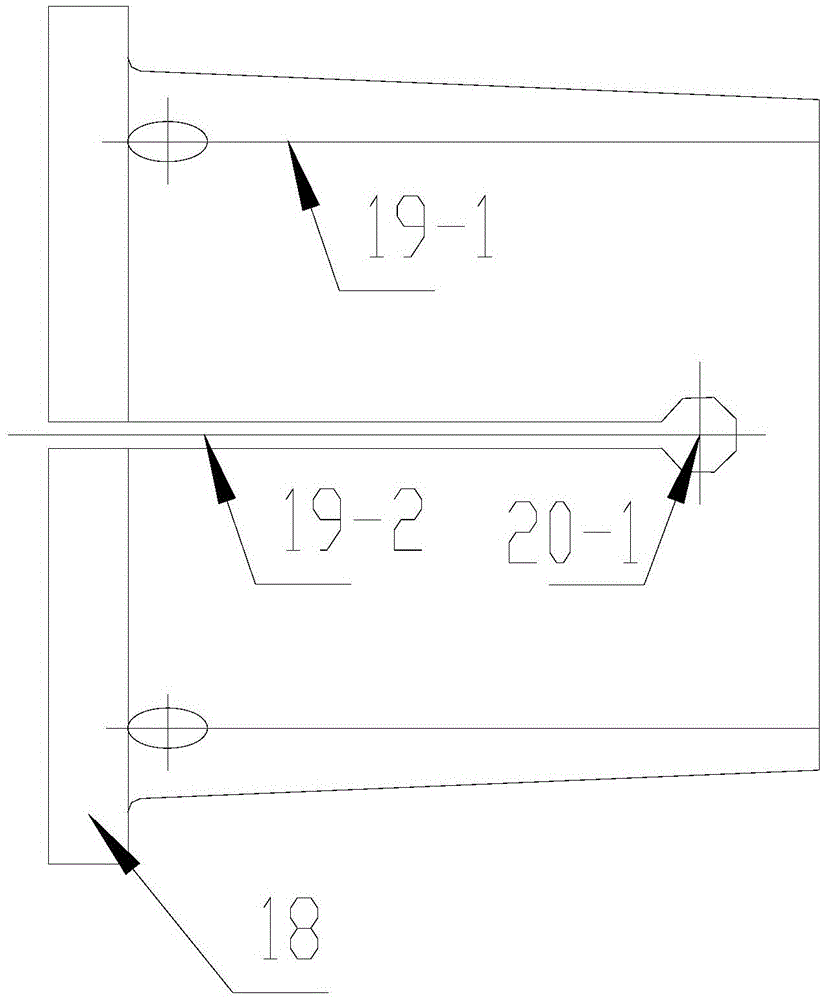

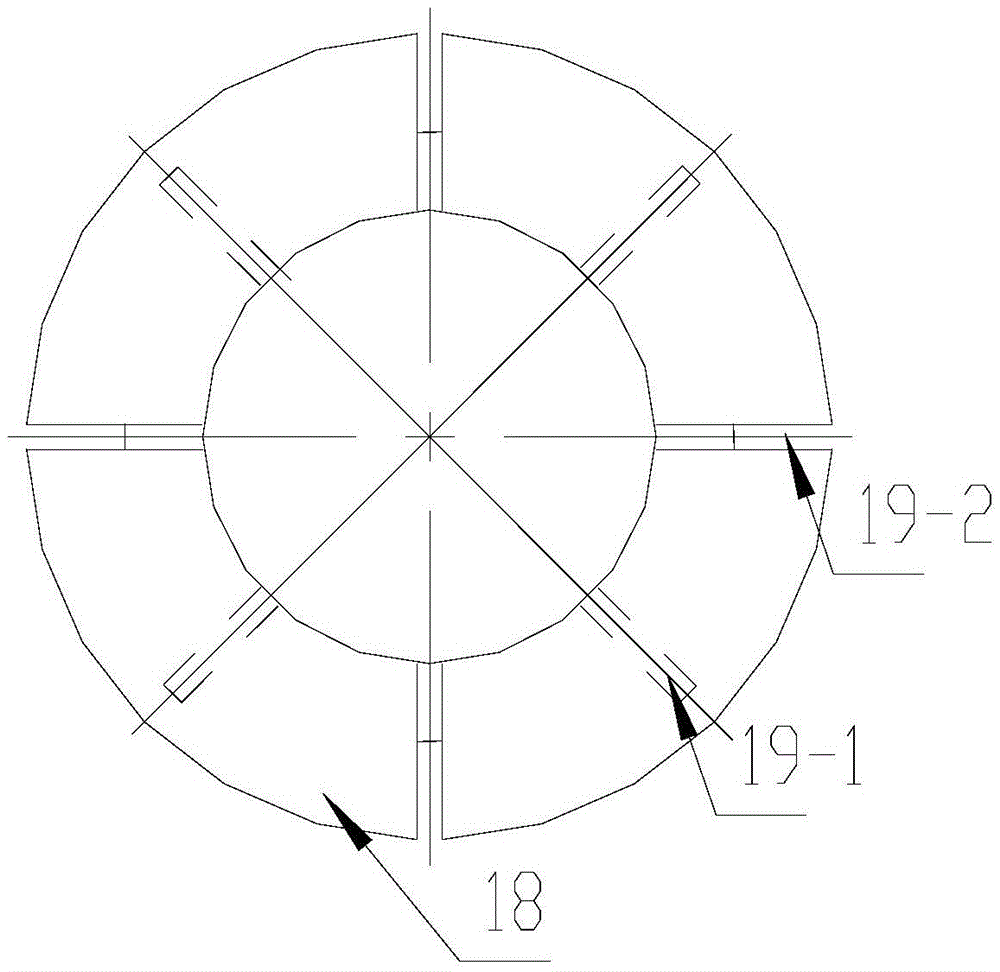

[0023] refer to Figure 1 to Figure 5 , the present invention provides a tool bar tailstock clamped with a cone sleeve, including a tailstock body 2 for supporting the tail end of the tool bar, and a tool bar 5 equipped with a tool 14, and a tailstock is provided on the tailstock body 2 body mounting hole, wherein, the first bearing 91 and the second bearing 92 whose inner hole is a tapered hole are installed in the tailstock body mounting hole, and the small diameter ends of the tapered holes of the first bearing 91 and the second bearing 92 face each other Installation, the rear end cover 3 that carries out axial positioning to the first bearing 91 and the front end cover 17 that the second bearing 92 is carried out axial positioning are respectively fixed at the two ends of the tailstock body mounting hole, in the first bearing 91 The first taper sleeve 4 is sleeved, and the second taper sleeve 12 is sleeved in the second bearing 92 (there is a gap between the opposite surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com