Stiffening framework and manufacturing method thereof, equipment and structural strengthening body

A skeleton and reinforcing rib technology, applied in the direction of structural elements, building reinforcements, building components, etc., can solve the problems of poor structural design and complex structure of prefabricated integrated buildings, and achieve uniform three-dimensional structure, good structural strength, and good combination. The effect of strength or tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solutions and advantages of the present application clearer, the present application will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

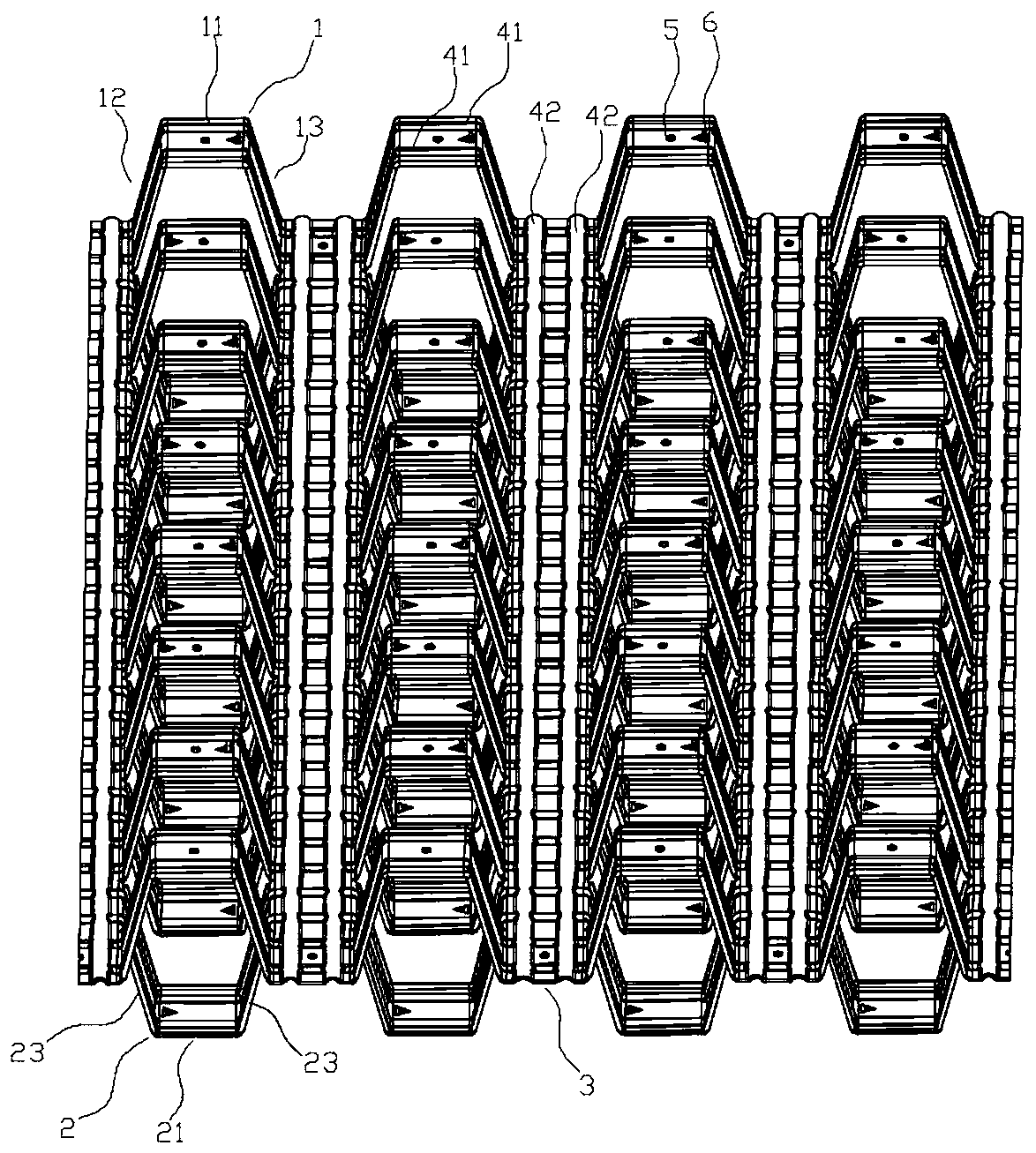

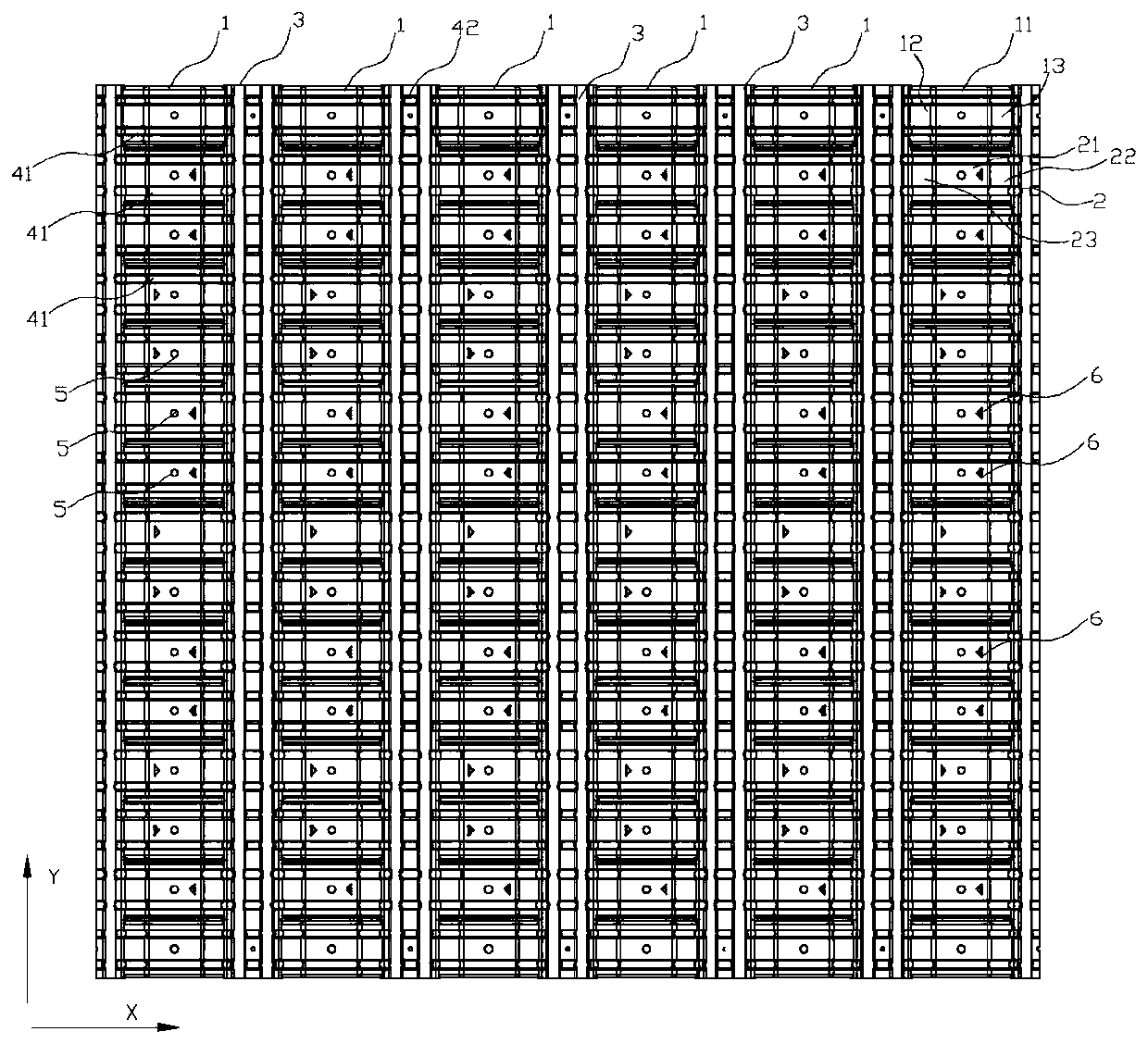

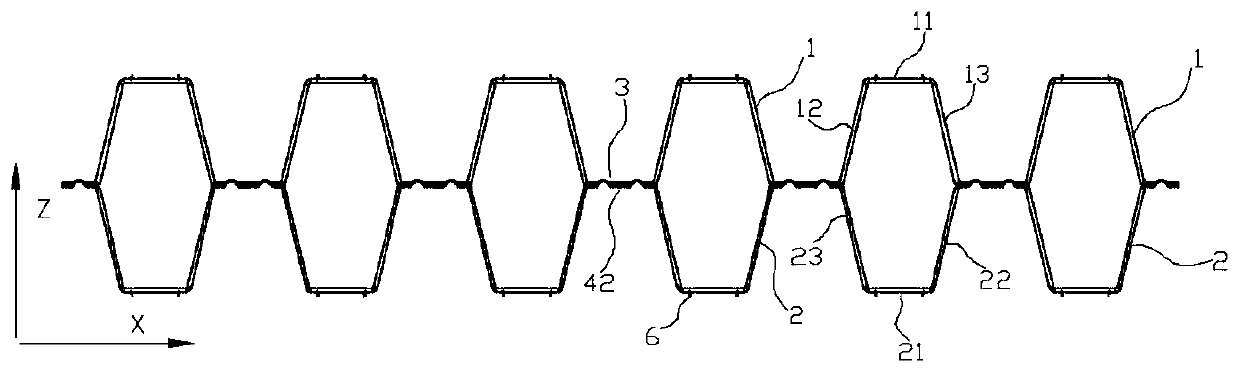

[0027] On the one hand, the present invention provides a stiffening frame, the stiffening frame is in the shape of a metal sheet and is integrally arranged, including several stiffening units,

[0028] The stiffening unit includes a first bending part 1 and a second bending part 2 arranged longitudinally, the first bending part 1 and the second bending part 2 have the same physical length, the first bending part 1 and the second bending part 2 The bending length direction X is the same, the first bending part 1 and the second bending part 2 are arranged front and rear in the bending width direction Y of the first bending part 1; the first bending part 1 and the second bending part 2 The projections in the bending wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com