A kind of building formwork side rib structure and building formwork

A technology of building formwork and side ribs, which is applied in the field of building formwork structures, can solve the problems of difficulty in formwork removal and insufficient flexibility of staggered hole connections, and achieve the effects of short formwork removal stroke, flexible assembly, and reduced restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

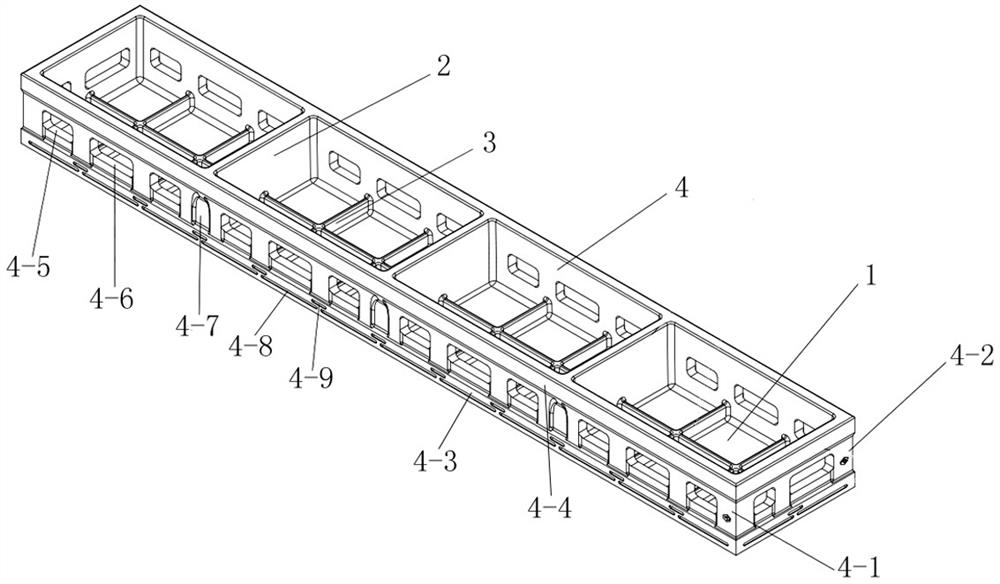

[0017] like figure 1 As shown, the building formwork of the present invention includes a panel 1, a central rib 2, a secondary rib 3 and a side rib 4, the side rib 4 is arranged on the peripheral edge of the panel 1 and is located on the back side of the panel 1, and the middle rib 2 and the secondary rib 3 are located on the On the back side of the panel 1, the middle rib 2 and the side rib 4 are connected to each other, and the top surface of the middle rib 2 is flush with the top surface of the side rib 4, and the back side of the panel 1 is divided into several large rectangular areas, and in each large rectangular area, a There is a secondary rib 3, which is connected with the middle rib 2, the height of the secondary rib 3 is smaller than that of the middle rib 2, and the secondary rib 3 divides the large rectangular area into several small rectangular areas. The side ribs 4 are used to be attached to the surface of other formworks when the building formwork is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com