Reversing operation mechanism

A technology of operating mechanism and joystick, which is applied to mechanical equipment, components with teeth, belts/chains/gears, etc., which can solve the problems of easy wear and labor-intensive operation, and achieve strong operability, avoid labor-intensive operation, and control light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the understanding of those skilled in the art, the structural principle of the present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

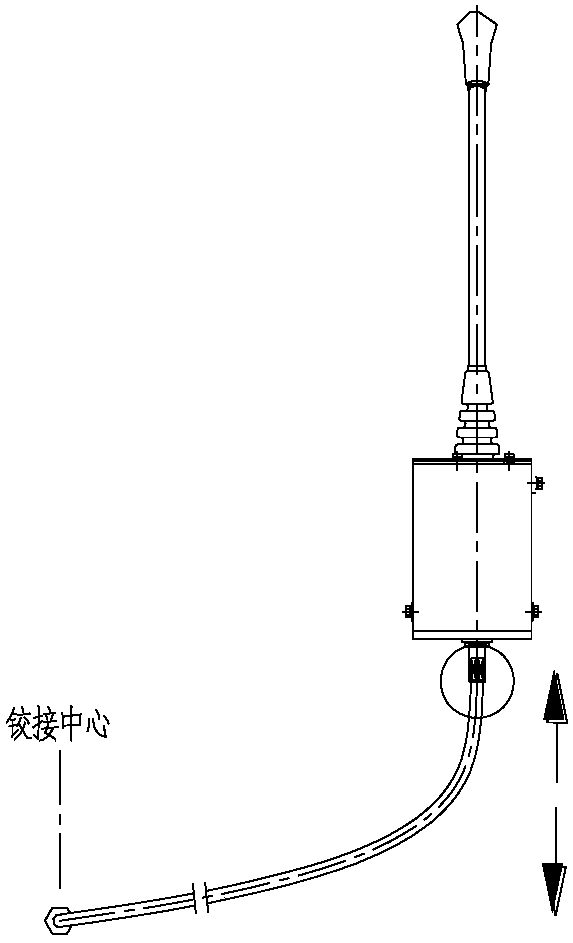

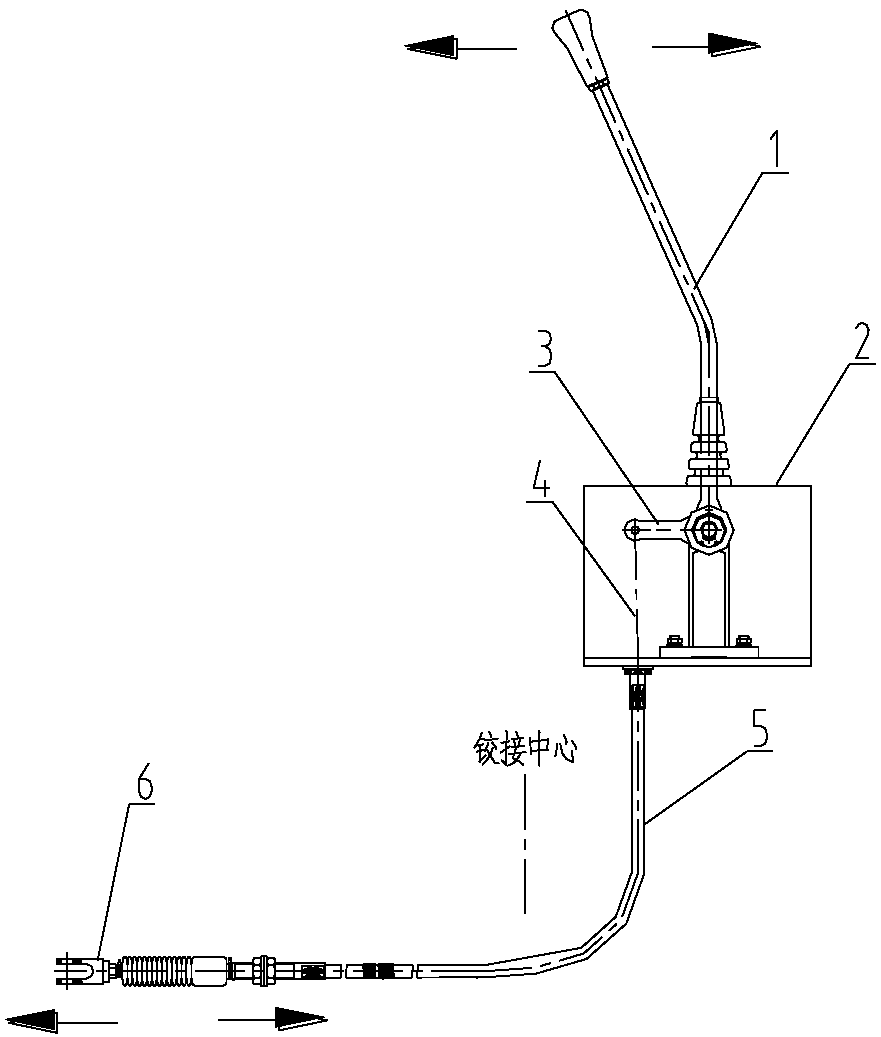

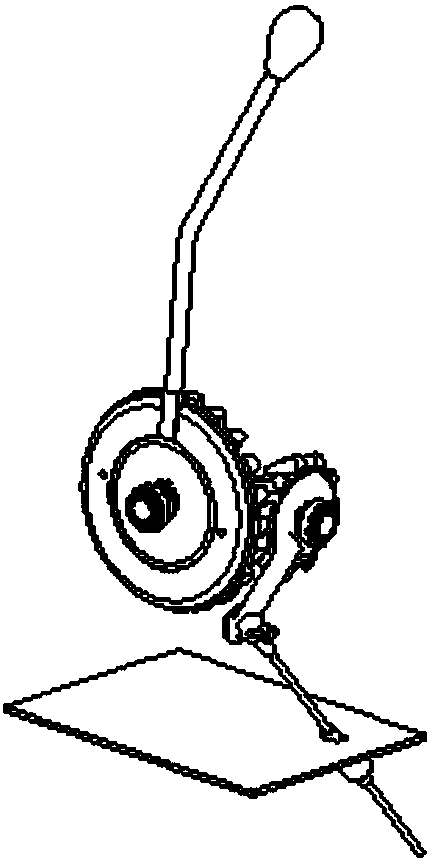

[0018] like figure 1 and 2 As shown, the schematic diagram of the overall structure of the central flexible shaft reversing operating mechanism in the prior art. Taking a loader as an example, the reversing mechanism usually passes through the hinge center and then leads to the front frame. The flexible shaft type reversing operating mechanism includes a joystick 1, a manipulation box 2 and a hinge center, wherein the manipulation box 2 includes a rocker 3 connected with the joystick 1, a flexible shaft 4, a flexible shaft sheath 5, and a The connecting fork 6 connected to the hinge center; the direction of the flexible shaft 4 at the bottom of the cab is to the left first ( figure 1 ) to the hinge center, after the hinge center and then for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com