Combustion control method of gas water heater

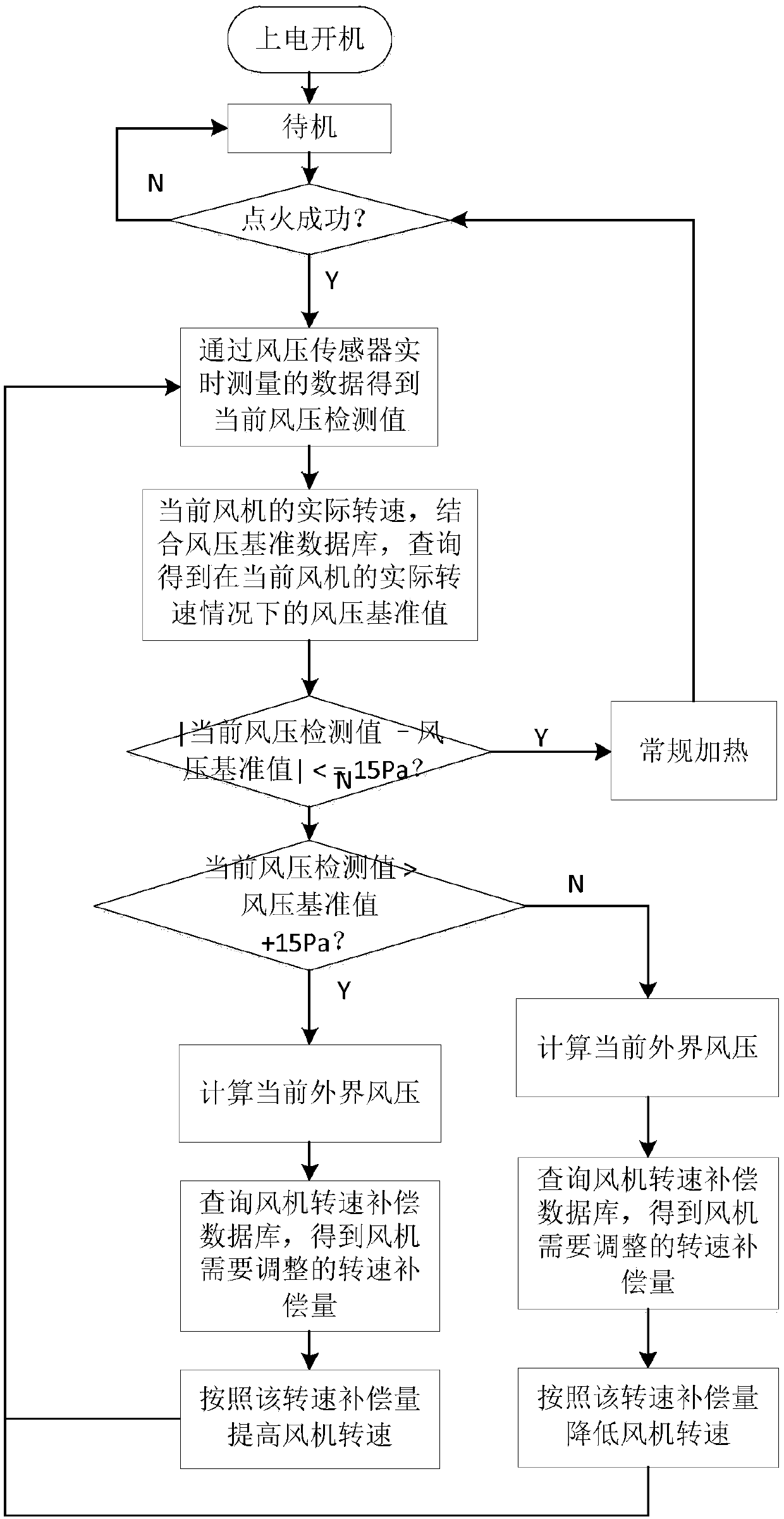

A technology of gas water heater and control method, which is applied to fluid heaters, lighting and heating equipment, etc., can solve problems such as inaccurate control methods, and achieve the effect of avoiding the influence of the detection value of a wind pressure sensor and making the control method accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

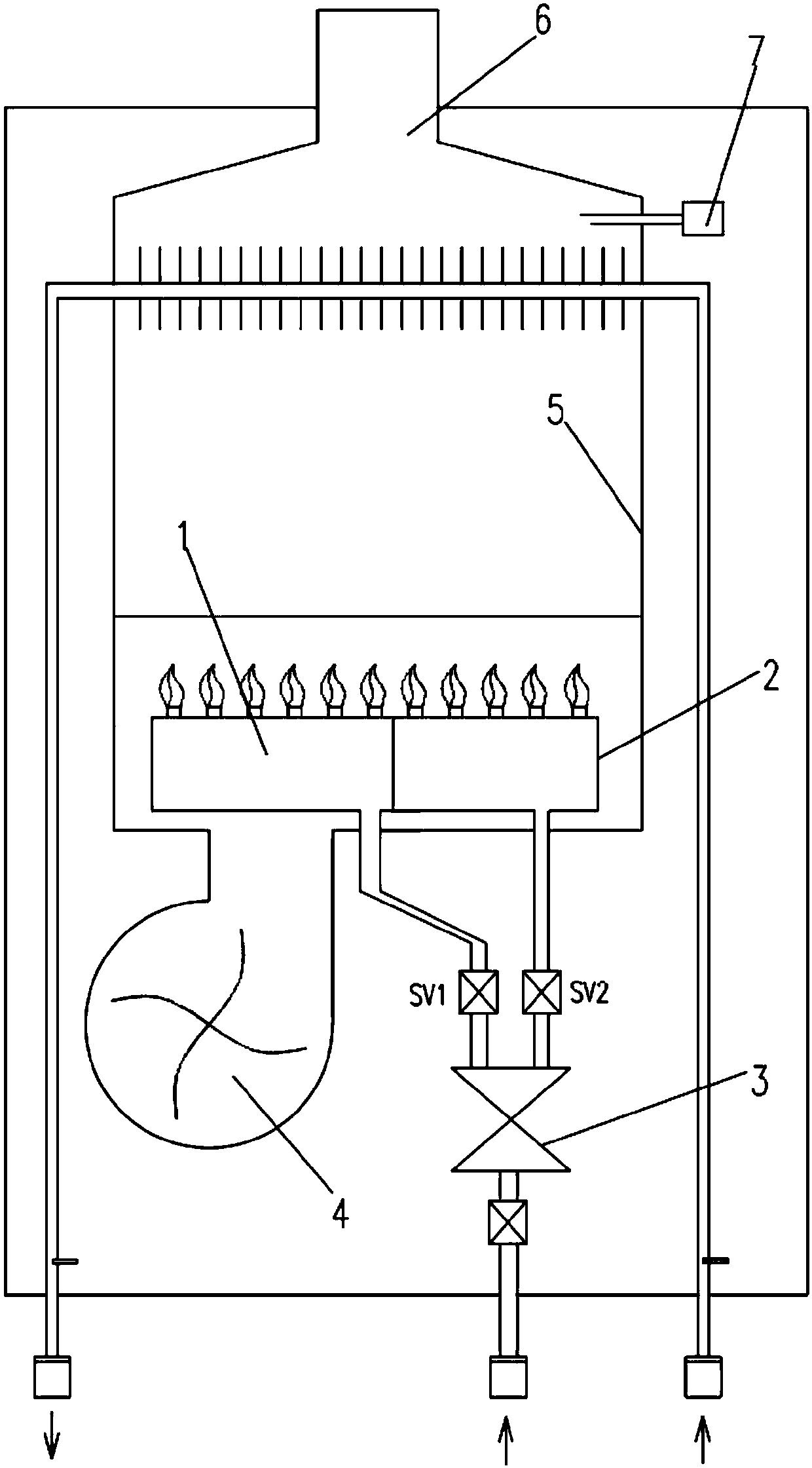

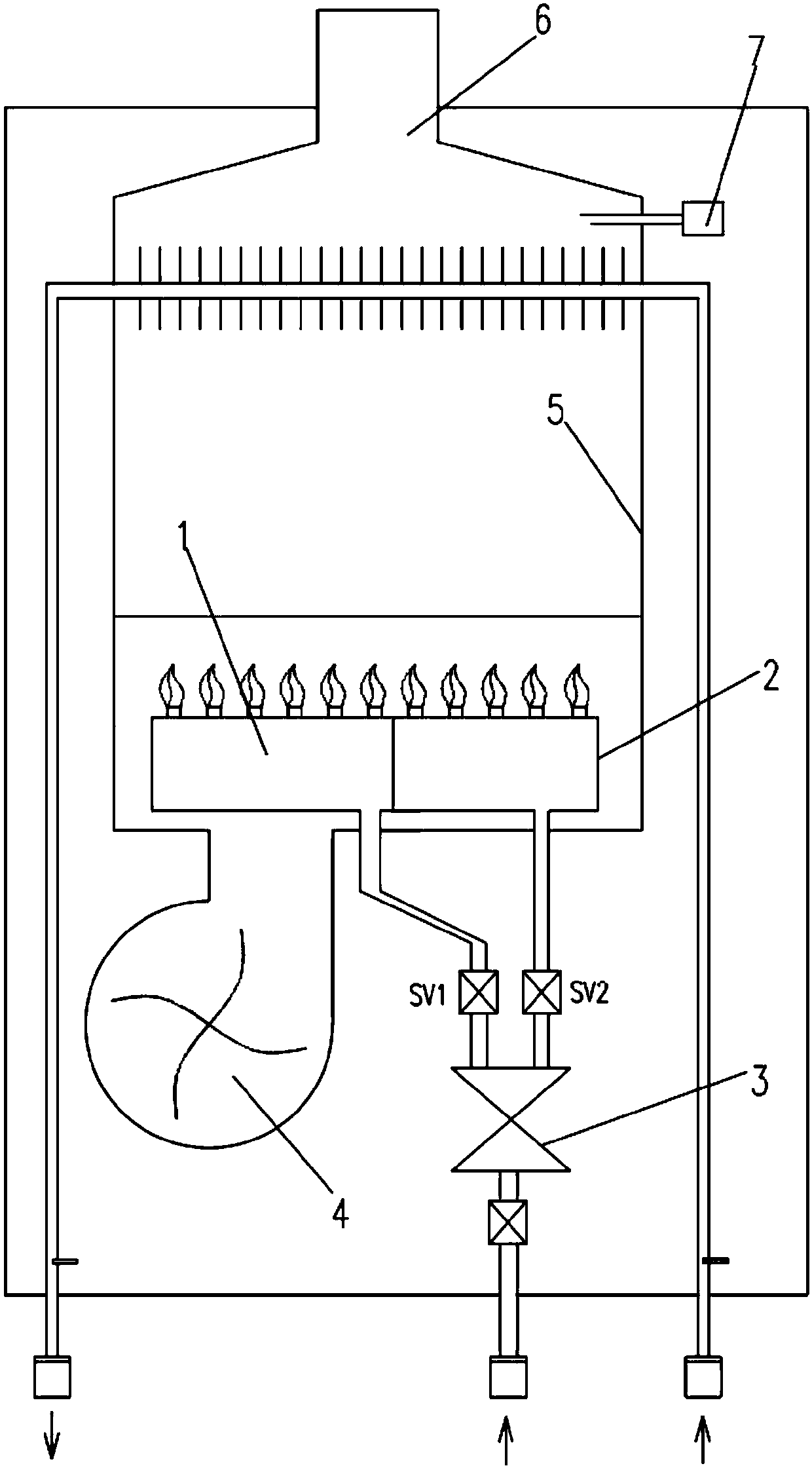

[0017] Such as figure 1 The gas water heater includes a burner 2 with a combustion chamber 1, a proportional valve 3 for controlling the amount of combustion gas entering the combustion chamber of the burner, and an air outlet connected to the combustion chamber for blowing air into the combustion chamber and The fan 4 that controls how much air is blown in, the controller (not shown) connected with the proportional valve 3 and the fan 4, the gas collection hood 5 with the exhaust port above the burner, the exhaust port of the gas collection hood 6. It communicates with the outside world. The exhaust port of the gas collecting hood is the exhaust port of the gas water heater. A wind pressure sensor 7 is arranged at or near the exhaust port, and the wind pressure sensor is also connected to the controller.

[0018] The wind pressure reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com