A Refrigeration System for Improving the Uniformity of Refrigerant Distribution at the Inlet of Multi-channel Evaporator

A refrigerant distribution and refrigeration system technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of high flow rate of gaseous refrigerant, compressor suction with liquid, loss of cooling capacity, etc., to improve Evaporating temperature, reducing dryness, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

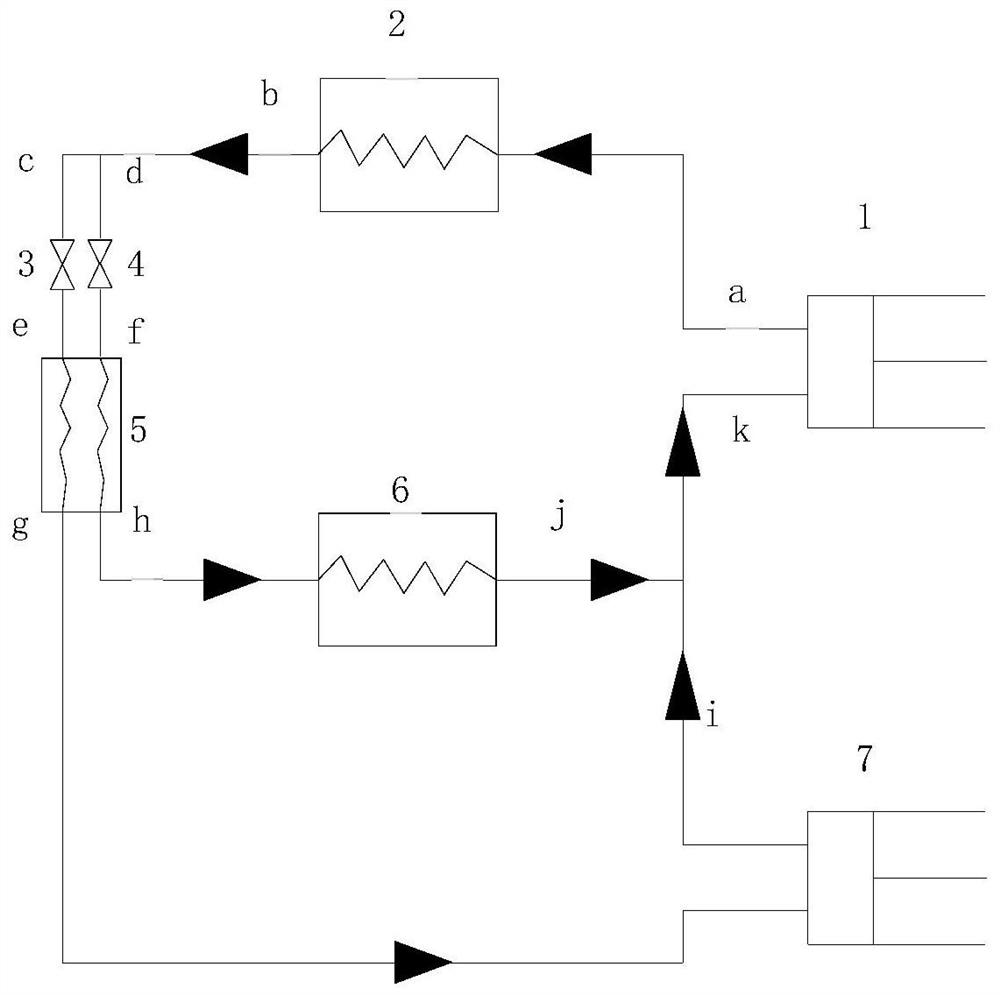

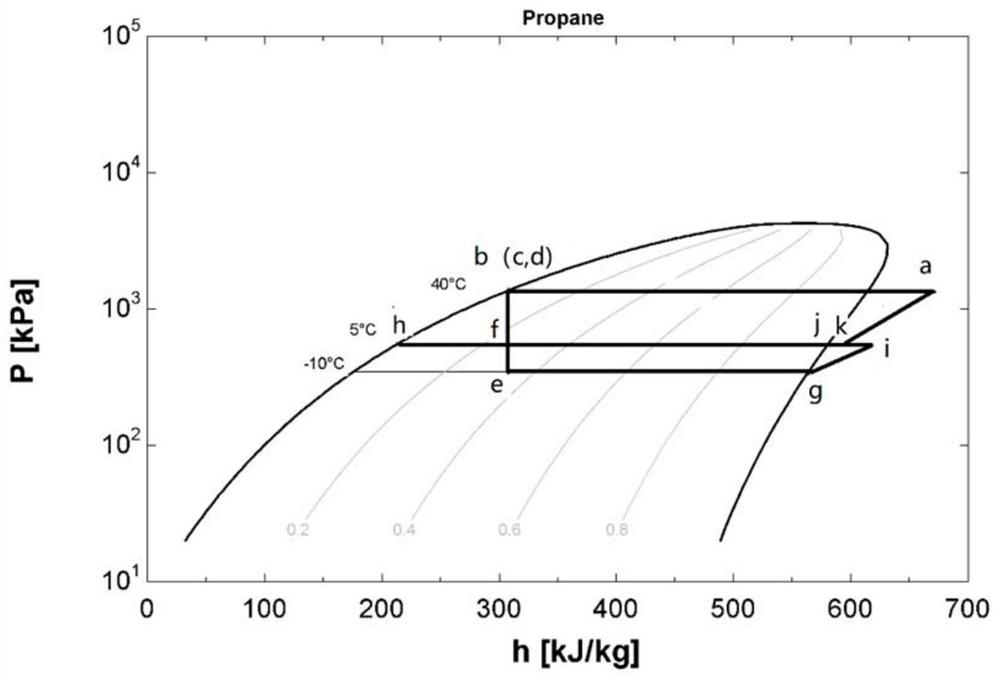

[0021] Attached below figure 1 Examples of the present invention will be described in detail, but the present invention is not limited to the following embodiments.

[0022] like figure 1 As shown, the refrigeration system using a dry evaporator according to the present invention includes a compressor 1, a condenser 2, an evaporator liquefier 5, a dry evaporator 6 and a second compressor 7, and the condenser 2 and the evaporator liquefier 5, a first throttling valve 3 and a second throttling valve 4 are arranged side by side, and the compressor 1, condenser 2, first throttling valve 3, evaporator liquefier 5, and second compressor 7 form the first throttling valve in sequence. In the first circuit, the compressor 1, condenser 2, second throttle valve 4, evaporator liquefier 5, and dry evaporator 6 sequentially form a second circuit; in the evaporator liquefier 5, the refrigeration in the first circuit The refrigerant exchanges heat with the refrigerant in the second circuit,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com