Cargo picking module

A module and cargo basket technology, which is applied to instruments, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. Items and other problems, to achieve the effect of reducing docking terminals, simple structure and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

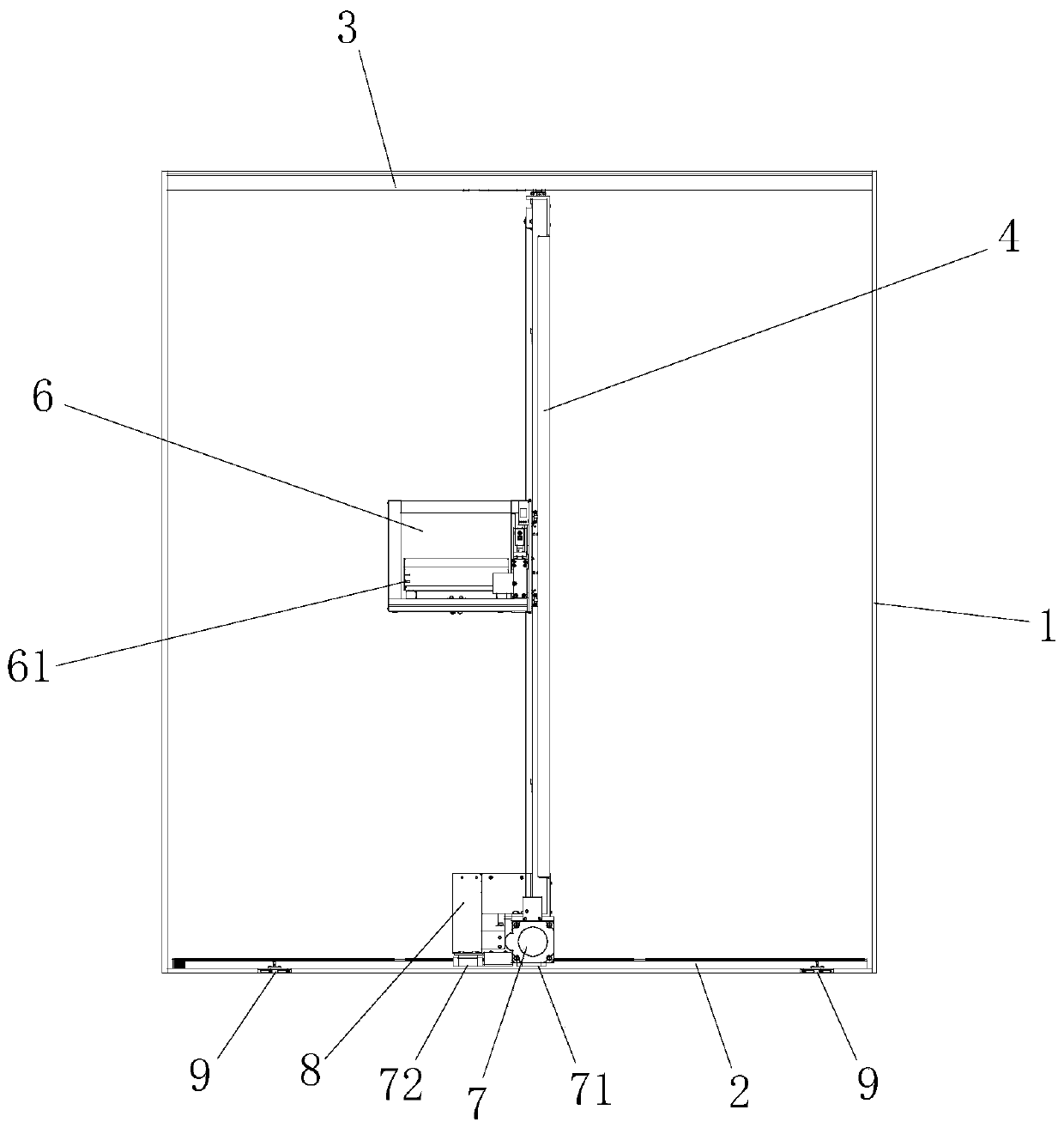

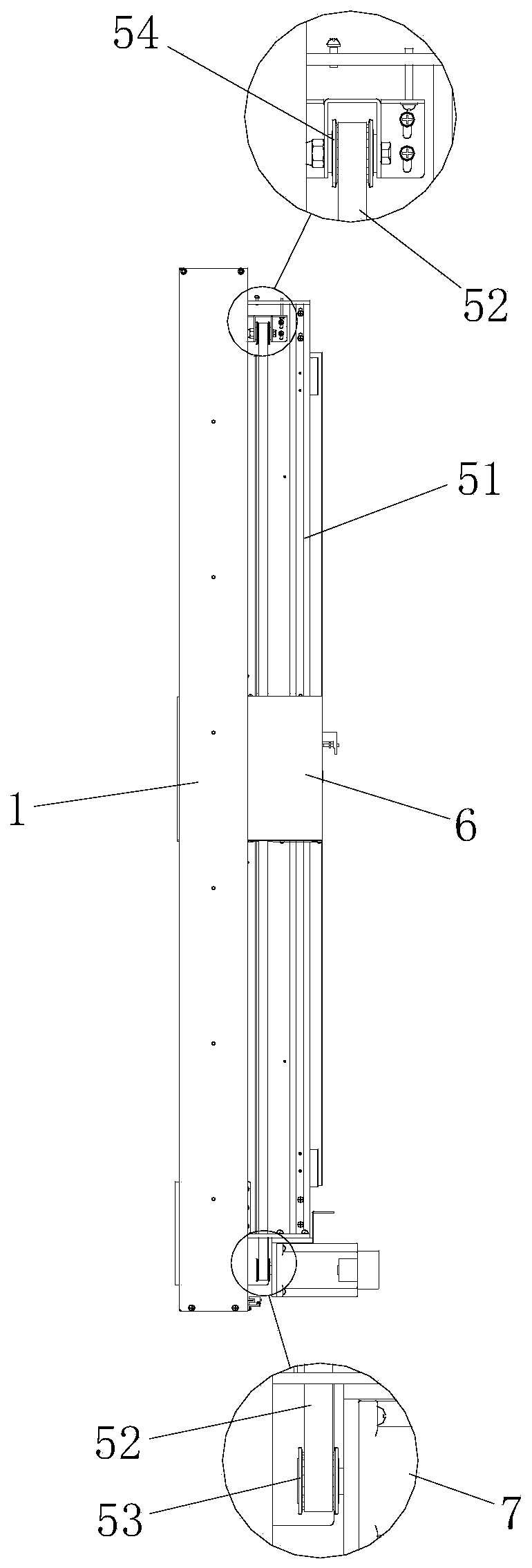

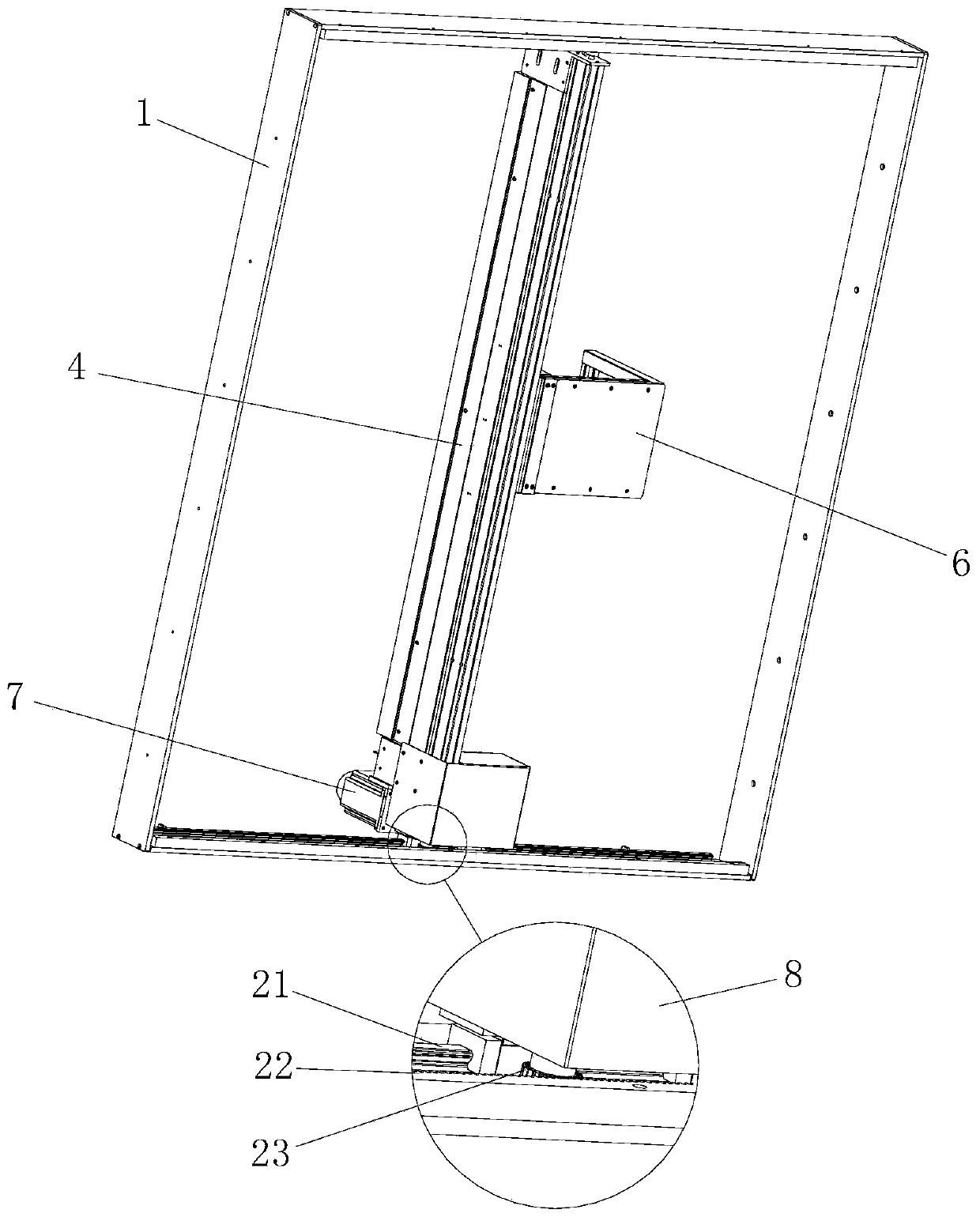

[0025] see Figure 1~3 , this embodiment provides a pick-up module, including a frame 1, the front and rear inner sides of the frame 1 are respectively provided with a first rail guide mechanism 2 and a second rail guide mechanism 3, and the first rail guide mechanism 2 and the second rail guide mechanism A mobile frame 4 is movable between the two guide rail guide mechanisms 3, and one side of the mobile frame 4 is provided with a guide rail transmission mechanism, and a cargo basket assembly 6 is movable on the guide rail transmission mechanism. There is a position for placing goods, and one end of the guide rail transmission mechanism is provided with a power assembly 7, and the power assembly 7 is fixed on the moving frame 4 through a motor mounting frame 8, and the moving frame 4 adopts an aluminum profile frame. The first power output end of the power assembly 7 is in transmission connection with the guide rail transmission mechanism, the second power output end of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com