Element analysis device and element analysis method

A technology of elemental analysis and quantitative analysis, applied in the direction of measuring devices, analysis materials, sampling devices, etc., to achieve the effect of stable calibration and high-precision analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

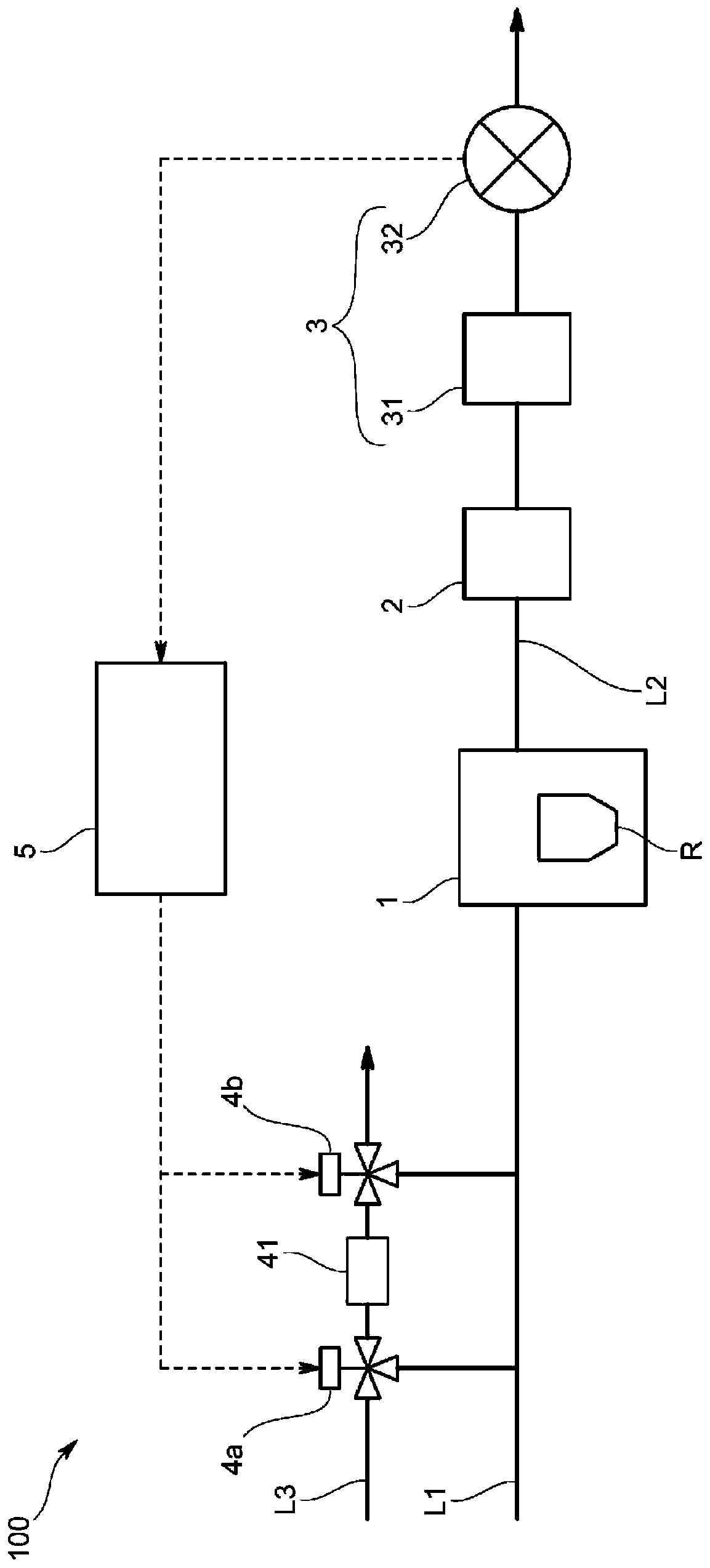

[0047] Next, an embodiment of the elemental analysis device of the present invention will be described with reference to the drawings.

[0048]

[0049] The elemental analysis device 100 of the present embodiment is used to analyze at least hydrogen contained in a metal material as a measurement sample. In the heating furnace 1, a graphite crucible R for accommodating the measurement sample is sandwiched by a pair of electrodes as a heating mechanism. By directly applying a voltage to the crucible R, the crucible R and the measurement sample in the crucible R are heated, the sample gas generated thereby is analyzed, and the hydrogen contained in the measurement sample is quantitatively analyzed.

[0050] In addition, the elemental analysis device 100 of this embodiment can be suitably used as a measurement sample if it is a steel material that needs to be evaluated at an extremely low hydrogen (H) concentration (for example, about several ppm) among metal materials.

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com