An optical fiber sensor humidity measurement calibration device and method

A technology of optical fiber sensor and humidity measurement, which is applied in the field of optical fiber sensor humidity measurement calibration device and sensor measurement humidity calibration device using TDLAS technology, which can solve the problems of long time, low calibration efficiency, and inability to achieve environmental stability, etc., and achieve stable calibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

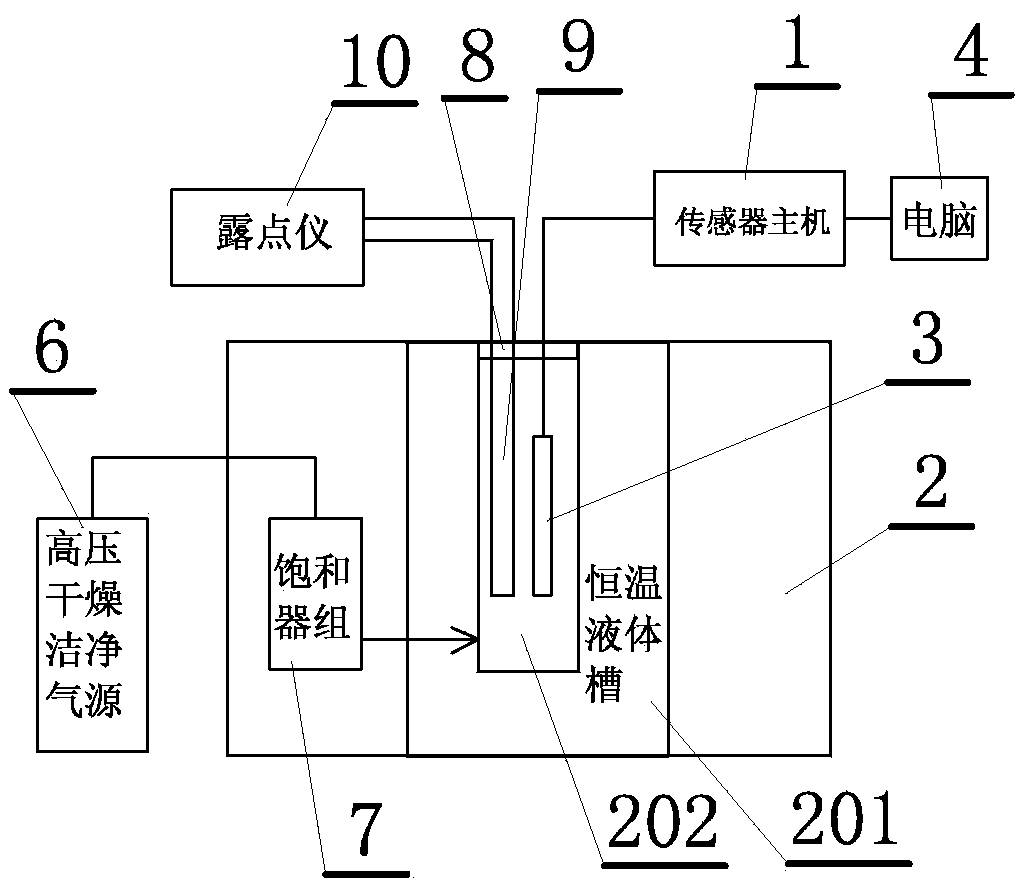

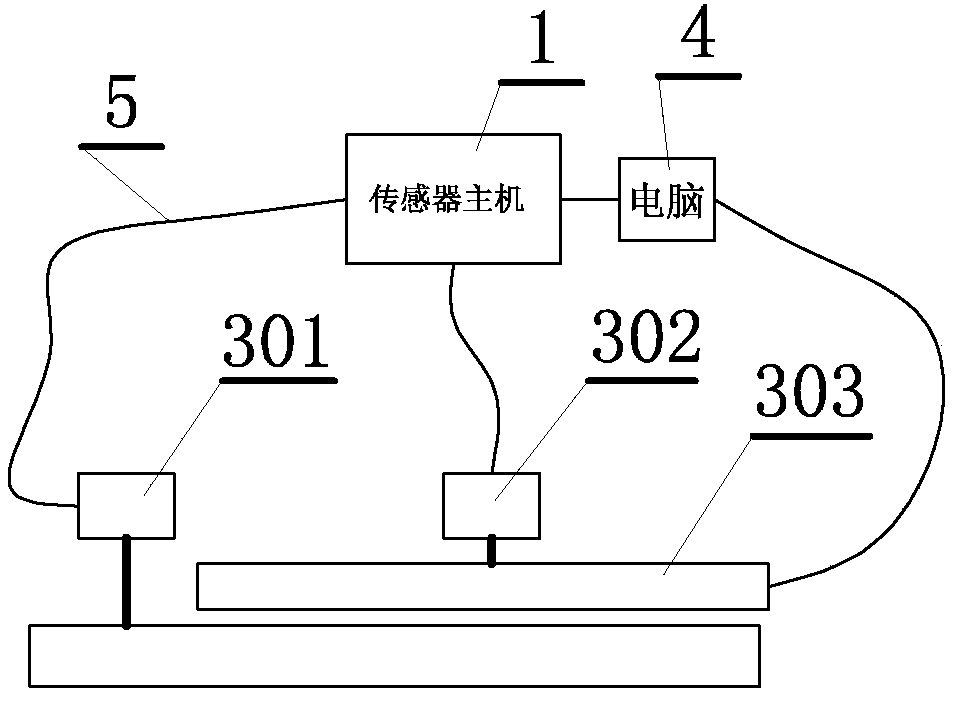

[0025] A kind of optical fiber sensor humidity measurement calibration device, such as figure 1 with figure 2 As shown, the device includes a calibrated optical fiber sensor humidity measurement host 1, a constant temperature and humidity box 2 and an optical coupler room 3, the optical fiber sensor humidity measurement host is connected to an analysis computer 4, and the analysis computer is used to calibrate the fiber optic sensor humidity measurement host Humidity compensation parameters, the optical coupler chamber is a prior art, the optical coupler chamber usually has a fiber collimator 301 and a PIN photodiode 302, the PIN photodiode is arranged on a horizontal rail 303, and the fiber collimator emits light , the PIN photodiode receives light and converts it into an electrical signal, and the fiber collimator and PIN photodiode are arranged on a horizontal rail to ensure that the collimator and the diode are coaxial; a controller controls the PIN photodiode to move hor...

Embodiment 2

[0032] A calibration method based on the optical fiber sensor humidity measurement calibration device in Embodiment 1, the content in Embodiment 1 should also be understood as the content in this embodiment, therefore, the device includes a calibrated optical fiber sensor humidity measurement host, Constant temperature and humidity chamber and optical coupler room, the fiber optic sensor humidity measurement host is connected to an analysis computer, the analysis computer is used to calibrate the humidity compensation parameters of the fiber optic sensor humidity measurement host, the optical coupler room is equipped with a fiber optic collimator and PIN photodiode, The PIN photodiode is set on a horizontal rail, the fiber collimator emits light, the PIN photodiode receives the light and converts it into an electrical signal, and a controller controls the PIN photodiode to move horizontally on the horizontal rail to adjust the PIN photodiode and fiber collimator The optical cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com