Wet type granulator

A technology of wet granulator and material cylinder, which is applied in chemical instruments and methods, methods for granulating raw materials, granulation in standing tanks/troughs, etc., which can solve the problem of easy opening of the cylinder lid door and short mixing time of dry powder , poor locking stability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

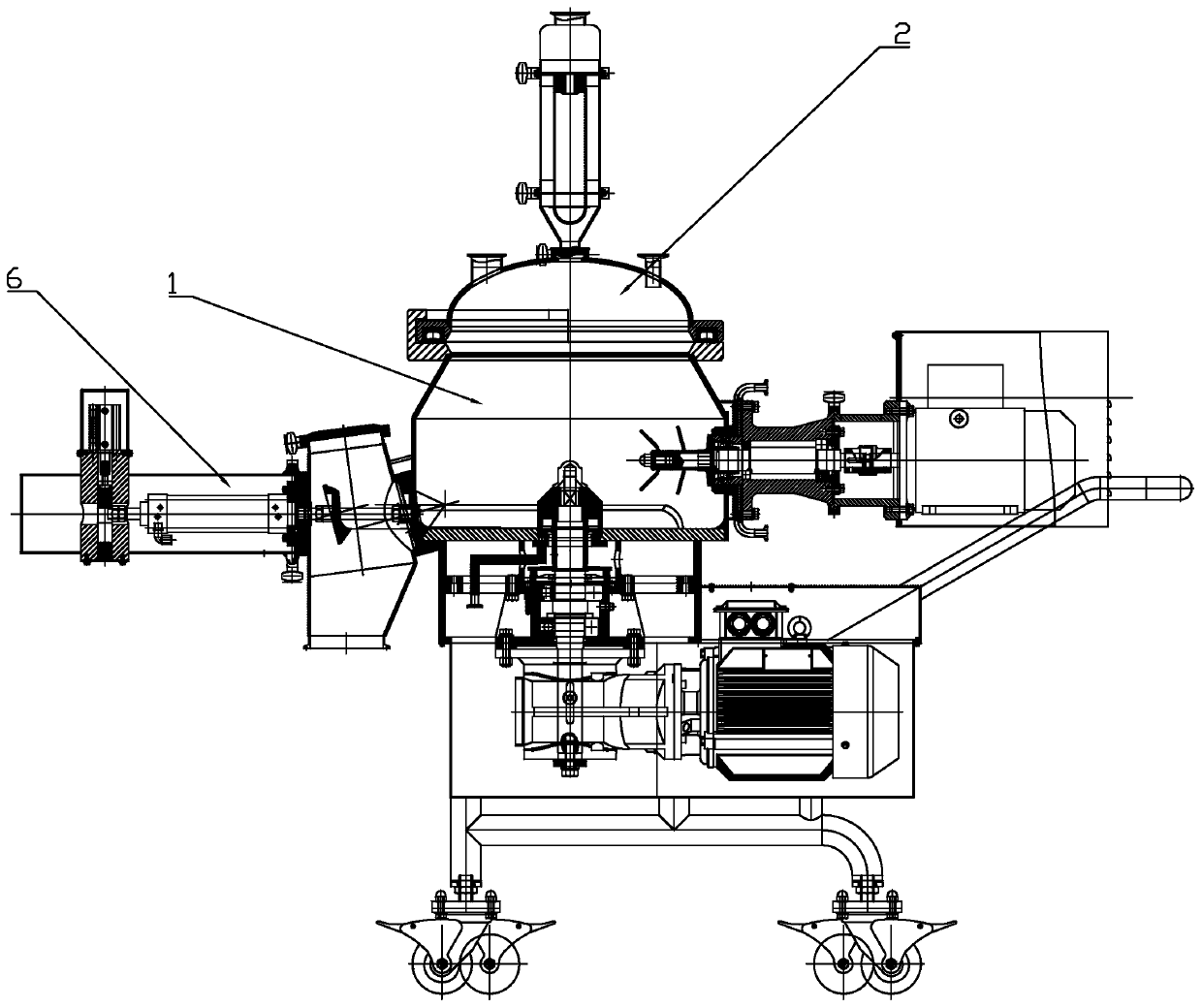

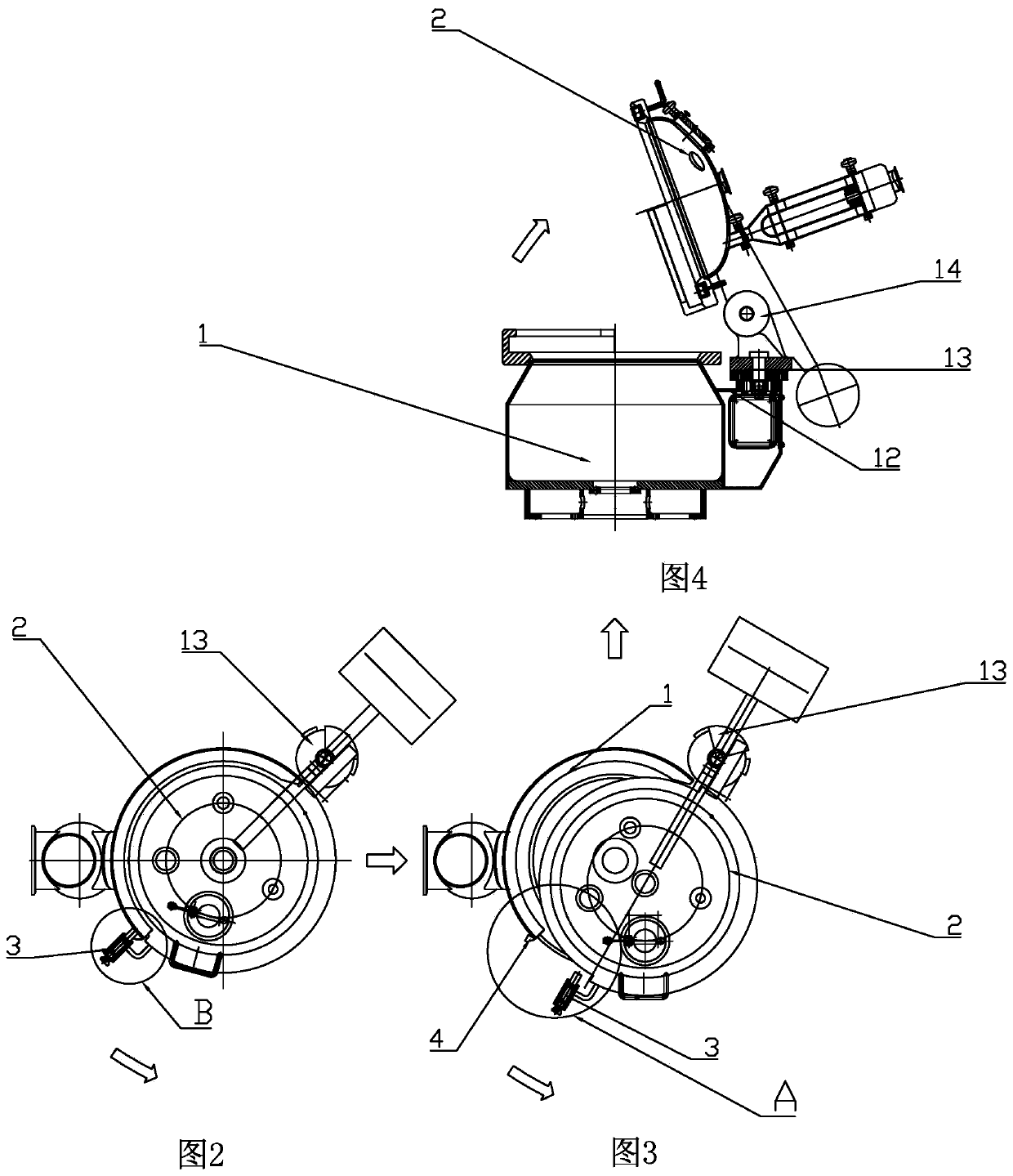

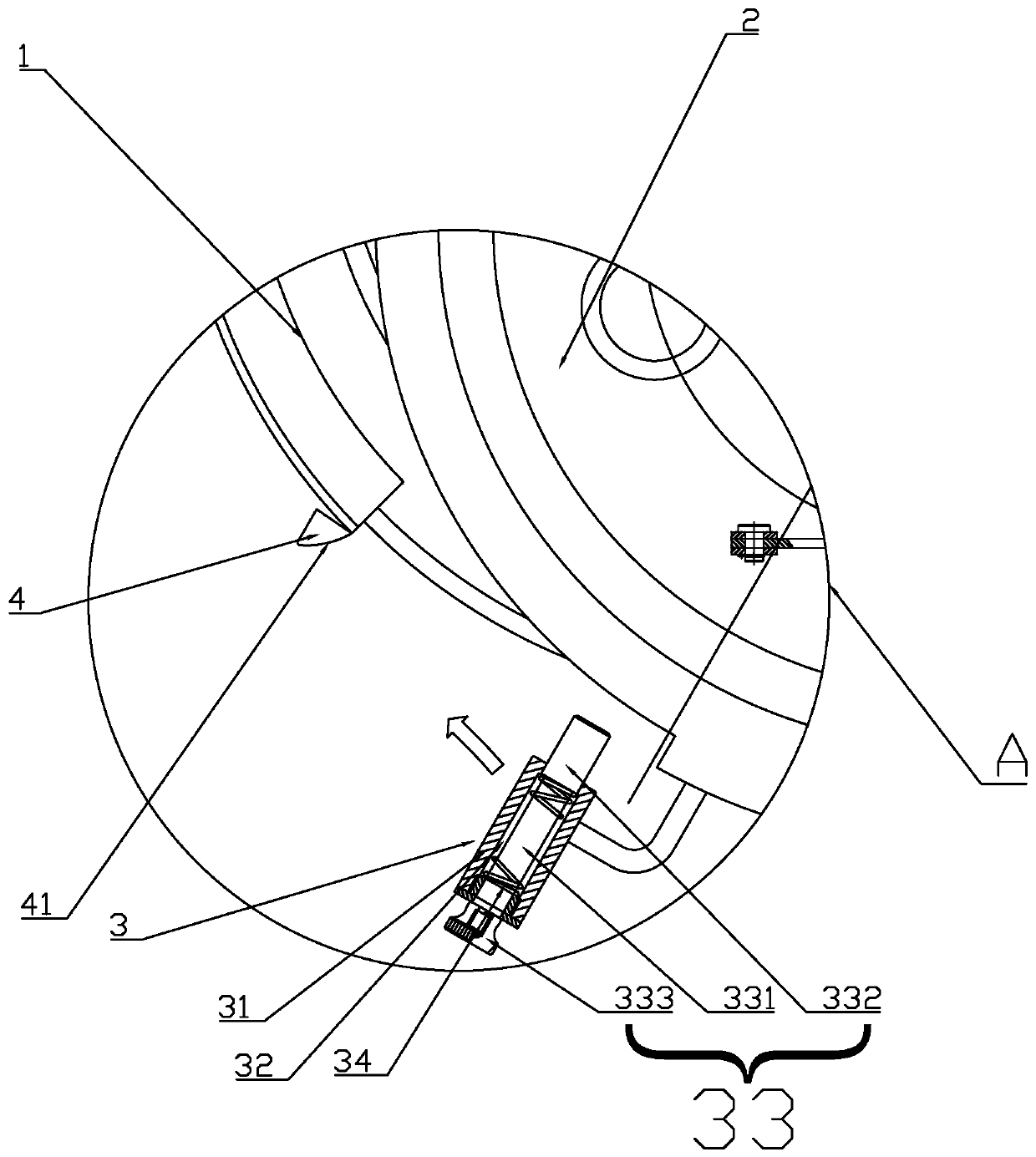

[0026] Depend on Figure 1 to Figure 10It can be seen that the present invention discloses a wet granulator, including a material tank 1, a cylinder cover 2 is rotated at the opening of the material tank 1, and a locking member 3 is arranged on the cylinder cover 2, and the lock The component 3 includes a lock case 31, the lock case 31 is provided with a first through groove 32, and a lock pin 33 is slidably arranged in the first through groove 32, and the lock pin 33 includes an intermediate rod 331 and a conflict rod 332, One end of the collision rod 332 is connected with one end of the middle rod 331 to form a collision platform 3321, and the other end protrudes from the first through groove 32. A through groove 32 is provided, and one end of the middle rod 331 protruding from the first through groove 32 is provided with a pin head 333, the diameter of the pin head 333 is set larger than the diameter of the first through groove 32, and the middle rod 331 is sleeved There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com