Protruding quantity process optimization method for bearing and device thereof

A technology of process optimization and protruding amount, applied in the field of bearing processing, can solve the problems of low efficiency and increased cost in the production process, and achieve the effect of effective and precise processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

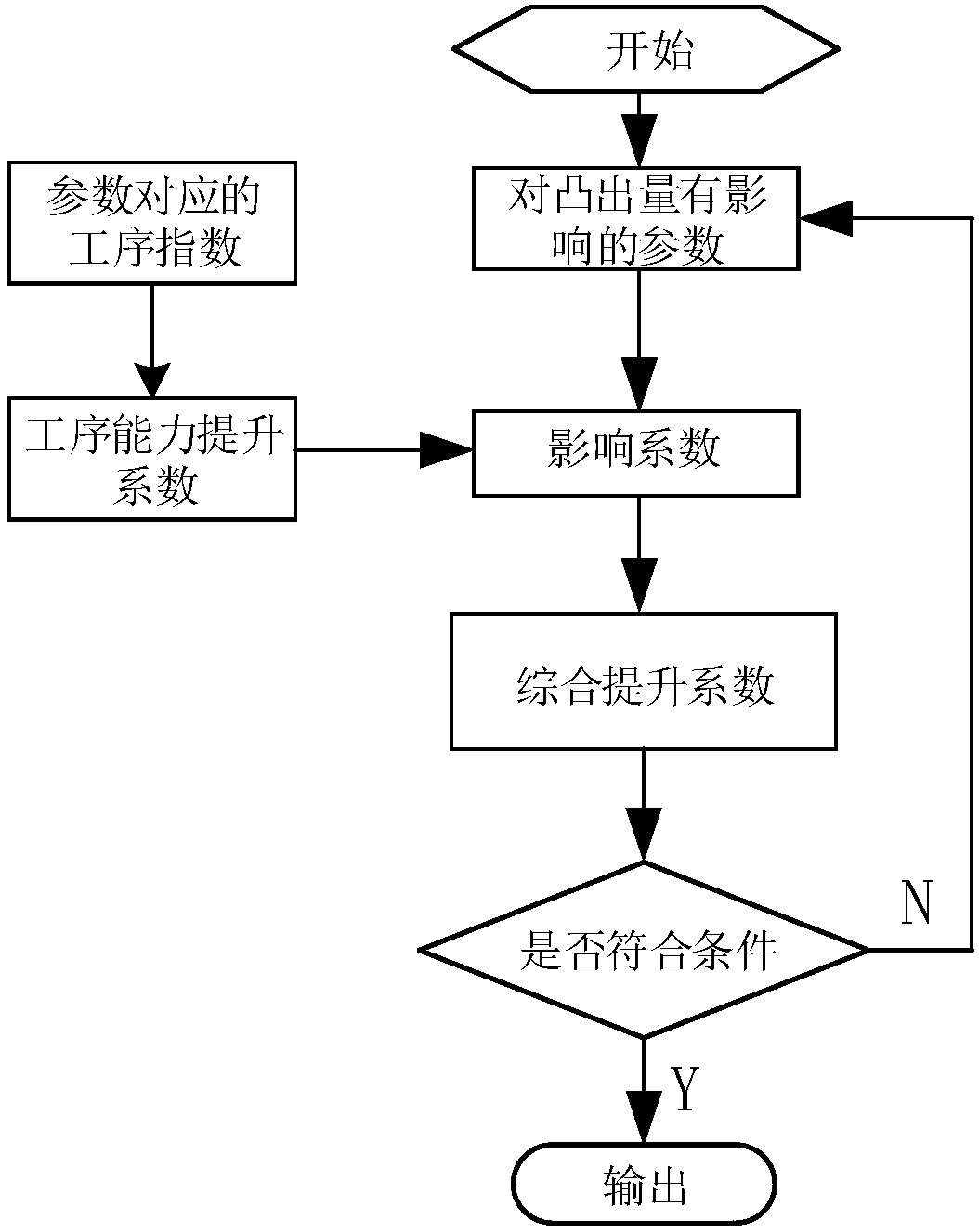

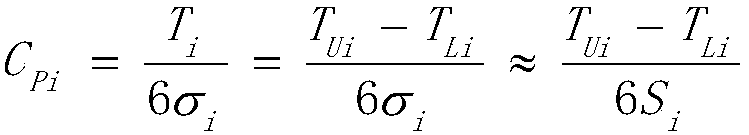

[0046] The present invention provides a process optimization method and device for a protrusion amount of a bearing. The process is optimized based on the processing capacity of the equipment, so as to quickly, economically and effectively realize the precise machining of bearings with different precision levels or special requirements. Firstly, the degree of influence of each parameter deviation on the bearing performance is calculated, and then the matching optimization is carried out according to the value of the equipment process capability index.

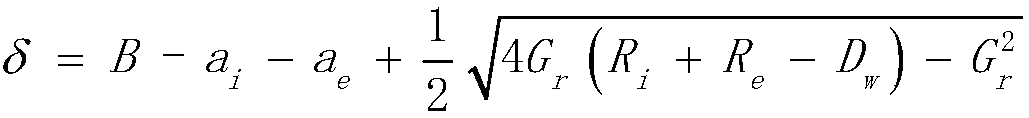

[0047] The present invention takes angular contact ball bearings as an example, and the flow chart of the technical solution adopted is as follows figure 1 As shown, customer customization requires that the protrusion amount is a very small value. Firstly, calculate the degree of influence of each parameter on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com