Marking and processing integrated device for cabinet door processing

A cabinet door and marking machine technology, applied in metal processing equipment, manufacturing tools, other manufacturing equipment/tools, etc., can solve problems affecting door panel processing and installation, a large amount of manpower input, low production efficiency, etc., to overcome processing operations The effect of low efficiency, improvement of machining accuracy, and improvement of machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

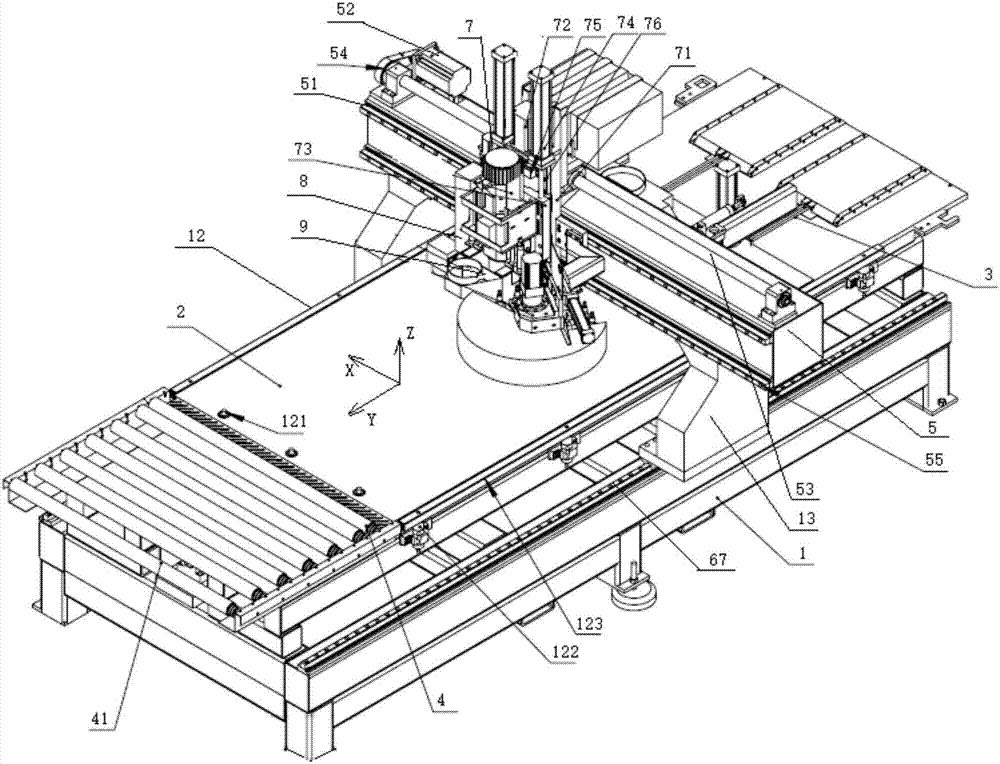

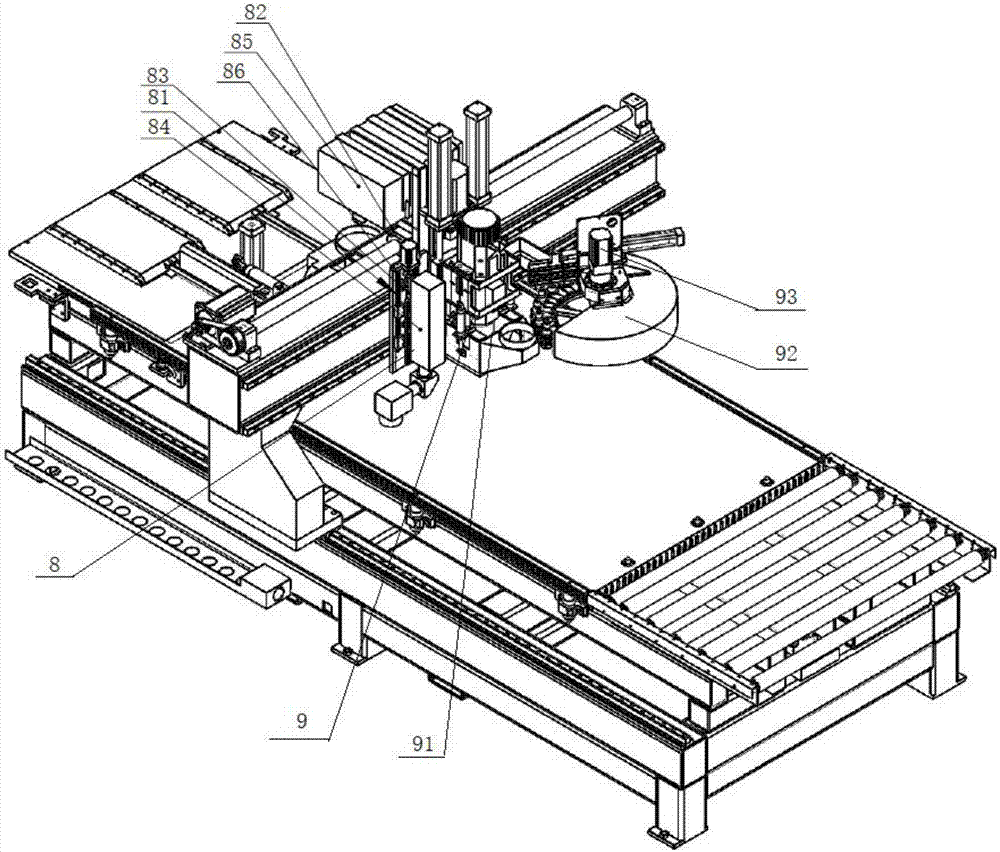

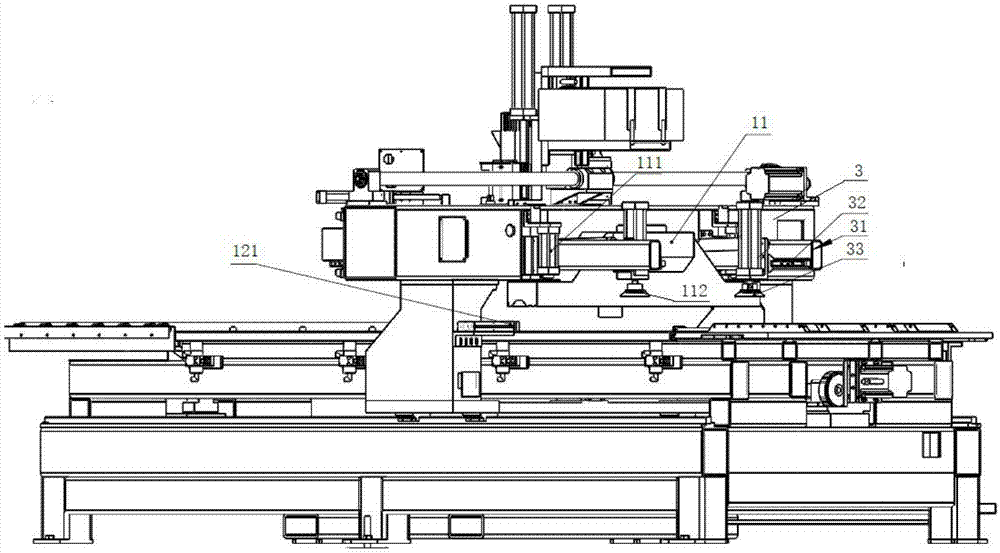

[0032] Embodiment 1: An integrated marking and processing device for cabinet door processing, including a frame 1, a processing platform 2 is provided on the frame, a feeding device 3 is provided at the front end of the processing platform 2, and a discharge device is provided at the tail end Device 4, an integrated marking and processing device fixed above the processing platform 2;

[0033] The integrated marking and processing device includes an X-direction driving device 5, a Y-direction driving device 6 and a Z-direction driving device 7. The Y-direction driving device 6 is set on the frame 1, and the X-direction drive device 5 is set on the The Y-direction drive device 6 and the Z-direction drive device 7 are built on the X-direction drive device 5, and the Z-direction drive device 7 is fixed with a marking mechanism 8 and a door panel processing mechanism 9, which are controlled by a central control system X-direction drive device 5, Y-direction drive device 6, Z-direct...

Embodiment 2

[0048] Embodiment 2: The structure of this embodiment is basically the same as that in Embodiment 1. The difference is that the Y-direction drive motor is a stepping motor, the Y-direction transmission rod is a gear rod, and the Y-direction drive motor drives the Y-direction drive through a worm gear reducer. The rack runs.

[0049] The X-direction drive motor is a stepper motor, the X-direction transmission rod is a gear rod, and the X-direction drive motor drives the X-direction transmission gear rod to run through the planetary reducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com