Automatic debonding machine

A combined and automatic technology, applied in microstructure devices, microstructure technology, etc., can solve the problems of substrate fragmentation and inability to complete substrate separation, and achieve the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings and embodiments.

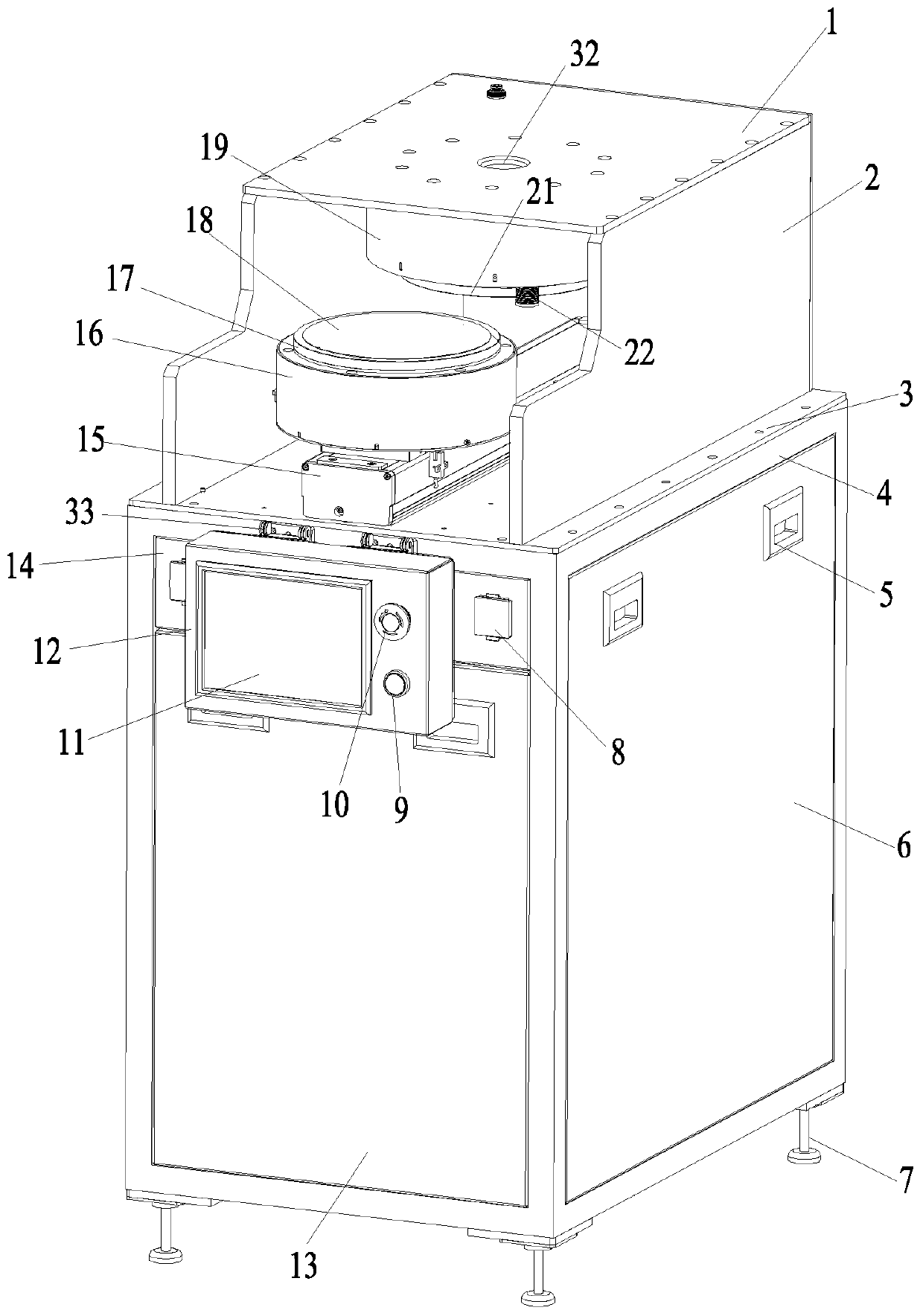

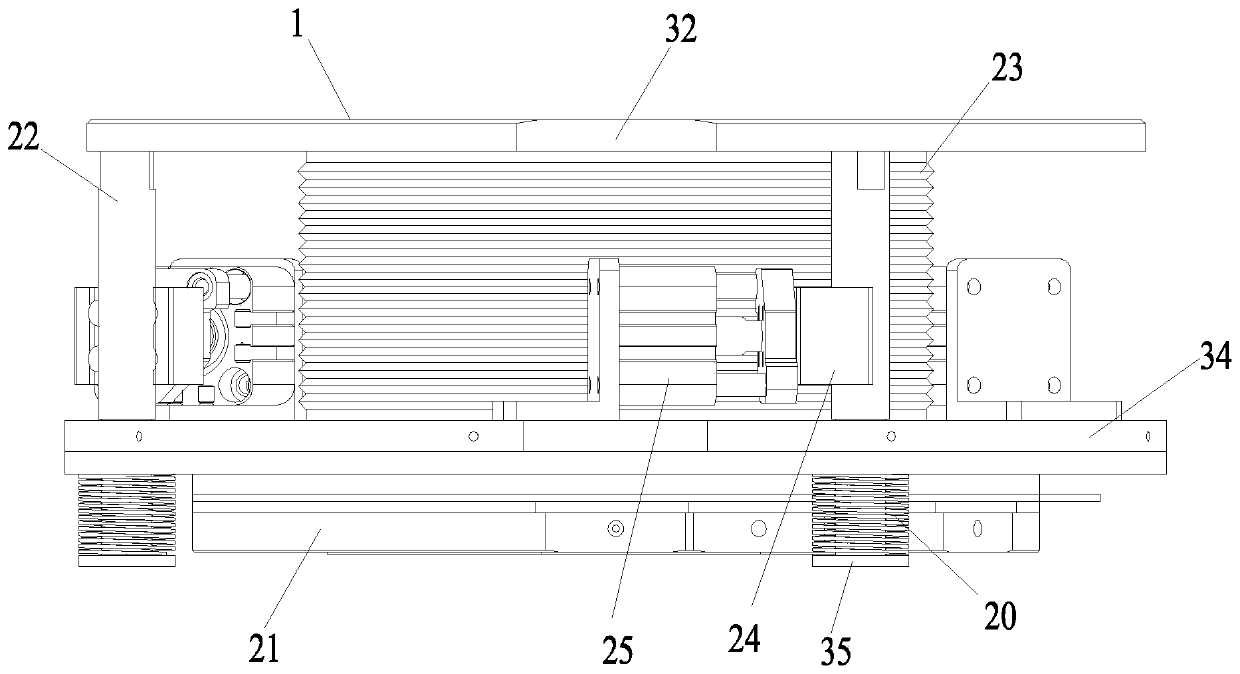

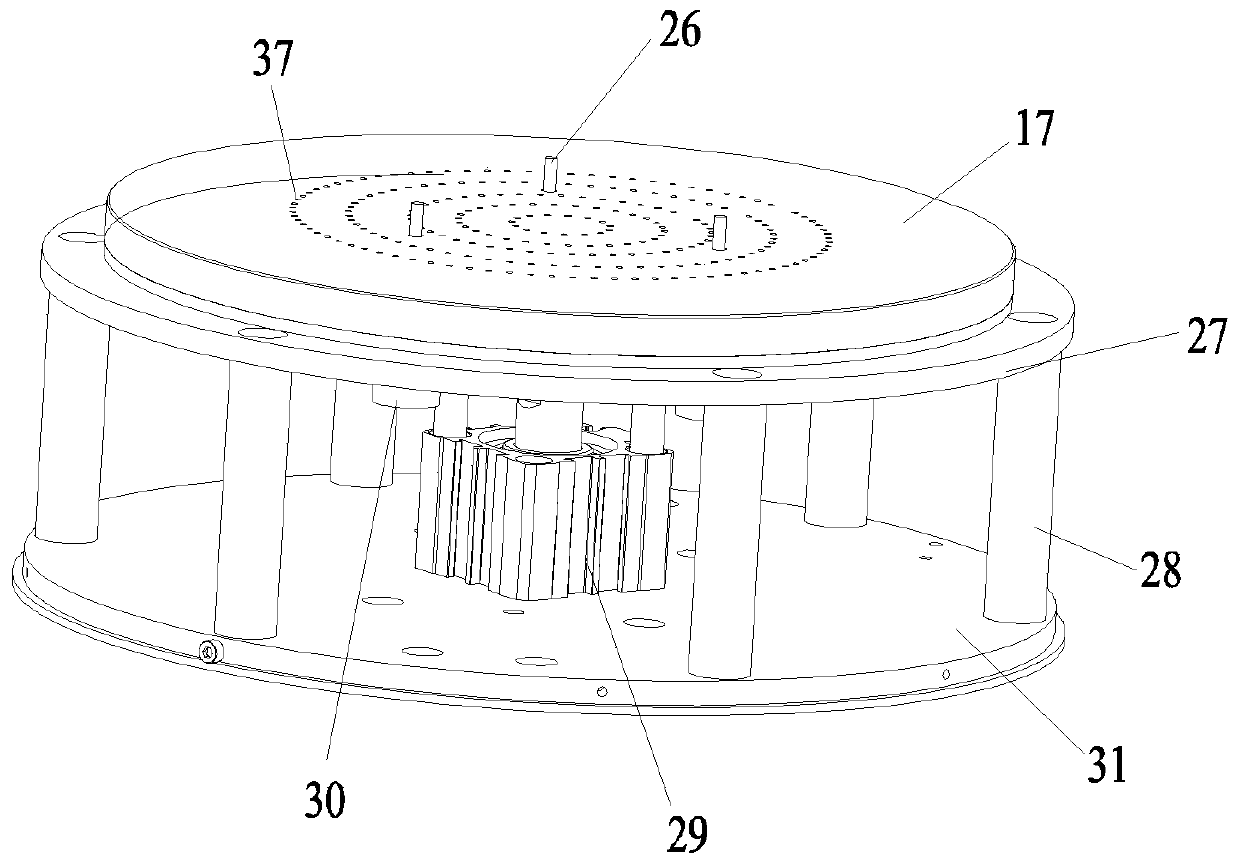

[0025] Such as figure 1 , figure 2 with image 3 As shown: in order to effectively ensure the parallelism between the upper vacuum chuck 21 and the lower vacuum chuck 17 during the debonding process and improve the success rate of debonding, the present invention includes a casing, and a bonding substrate group 18 capable of absorbing bonding is arranged in the casing The substrate adsorption and fixing top sheet device 16 and the substrate adsorption heating device 19 capable of heating the bonded substrate group 18, the substrate adsorption heating device 19 is located at the upper part of the casing, and the substrate adsorption and fixing top sheet device 16 is installed in the lower part of the casing through the manipulator 15, and the substrate adsorption and fixed top sheet device 16 can move to the right below the substrate adsorption heating device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com