Agricultural straw recovery fermentation device for environmental protection and installation method

The technology of a fermentation device and installation method is applied in the field of agricultural environmental protection straw recovery fermentation device, which can solve the problems of poor heat preservation effect and slow fermentation, and achieve good heat preservation effect and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

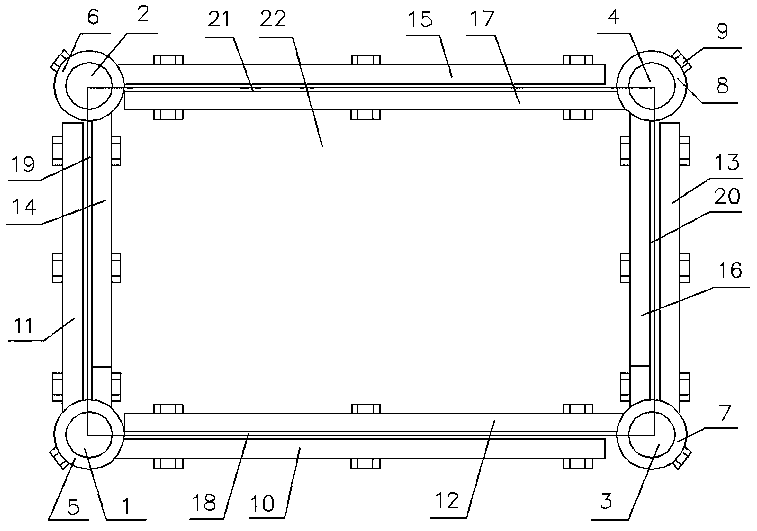

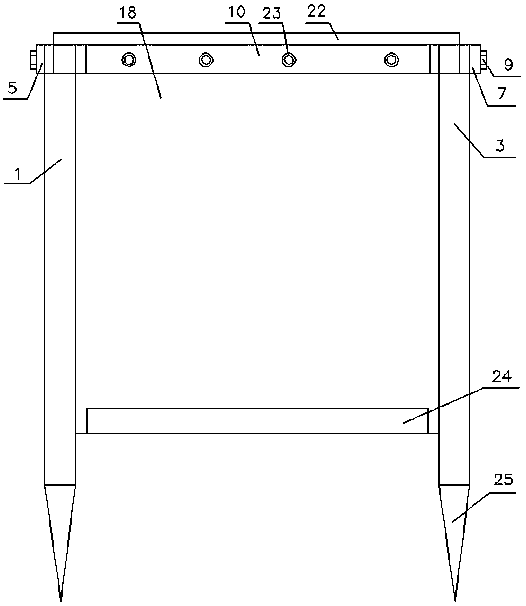

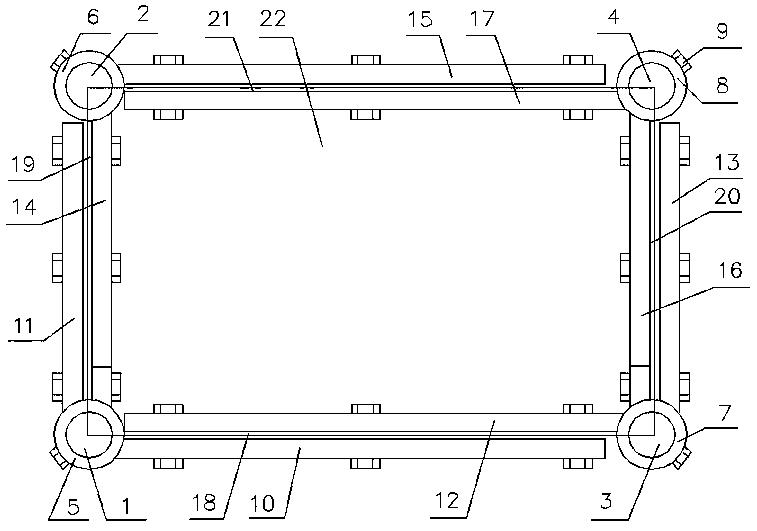

[0024] A straw recovery and fermentation device for agricultural environmental protection, which consists of: a vertical bar, the vertical bar includes a left front vertical bar 1, a left rear vertical bar 2, a right front vertical bar 3, and a right rear vertical bar 4, and the left front vertical bar The rod is connected to the left front fixed sleeve 5 and fixed by screws, the left rear vertical rod is connected to the left rear fixed sleeve 6 and fixed by screws, the right front vertical rod is connected to the right front fixed sleeve 7 and fixed by screws, the described The right rear vertical rod is connected to the right rear fixing sleeve 8 and fixed by screws 9. The left front fixing sleeve is welded to the front outer splint 10 and the left outer splint 11, and the right front fixing sleeve is welded to the front inner splint 12 and the right outer splint 13. The left rear fixing sleeve is welded to the left inner splint 14 and the rear outer splint 15, the right rea...

Embodiment 2

[0026] The straw recovery and fermentation device for agricultural environmental protection described in Example 1, the tops of the left front vertical bar, the left rear vertical bar, the right front vertical bar, and the right rear vertical bar are covered with plastic cloth 22 , the left side, the front side, the right side and the rear side of the top plastic cloth are folded down, the front outer splint and the front inner splint are sandwiched between the front plastic cloth and the left side, and the left outer splint The left plastic cloth and the front side are clamped between the left inner splint, the right plastic cloth and the right side are clamped between the right outer splint and the right inner splint, and the rear The rear plastic cloth and the rear side are sandwiched between the outer splint and the rear inner splint. The front plastic cloth, left plastic cloth, right plastic cloth, rear plastic cloth and top plastic cloth can keep the fermented straw warm ...

Embodiment 3

[0028] The straw recovery and fermentation device for agricultural environmental protection described in Example 2, the front outer splint, the front inner splint, the left outer splint, the left inner splint, the right outer splint, the The right inner splint, the rear outer splint, and the rear inner splint all have a group of fixing holes 23, and the overlapping connecting bolts are fixed between the fixing holes, and the front outer splint and the front outer splint Between the inner splints, between the left outer splint and the left inner splint, between the right outer splint and the right inner splint, between the rear outer splint and the rear inner splint The relative tension and compression adjustment between them, after the adjustment, the missing part is provided with an additional splint, the said additional splint has the said fixing hole, and the added splint can fill the front outer splint, front inner splint, left outer splint, left inner splint , right outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com