A kind of preparation method of polyaldehyde-based polymer tanning agent

A technology of polymer and polyaldehyde group, applied in the field of preparation of polyaldehyde-based polymer tanning agent, can solve the problems of low aldehyde group content and low aldehyde group density, and achieve high aldehyde group content, high aldehyde group density, excellent water soluble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 744 g of water and 3 g of sodium hypophosphite are placed in the reactor, stirred to dissolve and heated to 70 o C, dissolve 3 g of ammonium persulfate with 100 g of water, drip the initiator solution and 150 g of hydroxyethyl acrylate into the above-mentioned sodium hypophosphite solution synchronously and uniformly within 2 h, and then keep warm for 6 h to obtain Hydroxyethyl acrylate polymer; cool the above polymer solution to 10 o C, add 0.36 g (accounting for 0.1mol% of hydroxyethyl acrylate) 4-benzoyloxy-2,2,6,6-tetramethylpiperidine-oxyl radical and 13 g (accounting for 10mol% of hydroxyethyl acrylate) %) sodium bromide, and adjust the pH to 9.4 with sodium hydroxide solution, then dropwise add 169 g (accounting for 30 mol% of hydroxyethyl acrylate) potassium hypochlorite solution, and keep warm for 90 min to obtain a polyaldehyde-based polymer tanning agent.

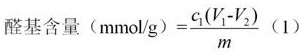

[0025] The aldehyde group content of polyaldehyde-based polymer tanning agent was determined by potent...

Embodiment 2

[0030] Place 600 g of water and 3 g of sodium hypophosphite in the reactor, stir to dissolve and heat up to 85 o C, dissolve 9 g of potassium persulfate with 100 g of water, drip the initiator solution and 300 g of hydroxyethyl acrylate into the above-mentioned sodium hypophosphite solution synchronously and uniformly within 3 h, and then keep warm for 6 h to obtain Hydroxyethyl acrylate polymer; cool the above polymer solution to 5 o C, add 0.40 g (accounting for 0.1 mol% of hydroxyethyl acrylate) 2,2,6,6-tetramethylpiperidine-oxyl radical and 26.6 g (accounting for 10 mol% of hydroxyethyl acrylate) sodium bromide, and use hydrogen Sodium oxide solution was used to adjust the pH to 9.4, and then 278.3 g (accounting for 30 mol% of hydroxyethyl acrylate) sodium hypochlorite solution was added dropwise and kept for 90 min to obtain a polyaldehyde-based polymer tanning agent.

[0031] Measure the aldehyde group content of this tanning agent with the method described in Example 1...

Embodiment 3

[0033] 690 g of water and 4 g of sodium hypophosphite were placed in the reactor, stirred to dissolve and heated to 85 o C, dissolve 6 g of ammonium persulfate with 100 g of water, drip the initiator solution and 200 g of hydroxypropyl acrylate into the above-mentioned sodium hypophosphite solution synchronously and uniformly within 3 h, and then keep warm for 4 h to obtain Hydroxypropyl acrylate polymer; cool the above polymer solution to 5 o C, add 0.33 g (accounting for 0.1 mol% of hydroxypropyl acrylate) 4-acetamido-2,2,6,6-tetramethylpiperidine-oxyl radical and 16 g (accounting for 10 mol% of hydroxypropyl acrylate) bromine sodium chloride, and adjust the pH to 8 with sodium hydroxide solution, then dropwise add 166g (accounting for 30mol% of hydroxypropyl acrylate) sodium hypochlorite solution, and keep warm for 90 minutes to obtain a polyaldehyde-based polymer tanning agent.

[0034] Measure the aldehyde group content of this tanning agent with the method described in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com