Safety monitoring device and method for water-cooling wall of gasification furnace

A technology of safety monitoring and water-cooled wall, which is applied in the direction of furnace monitoring device, furnace cooling device, furnace, etc., can solve the problems of difficult replacement, large area of water-cooled wall, difficult installation and maintenance, etc., and achieve simple installation and maintenance and accurate measurement results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

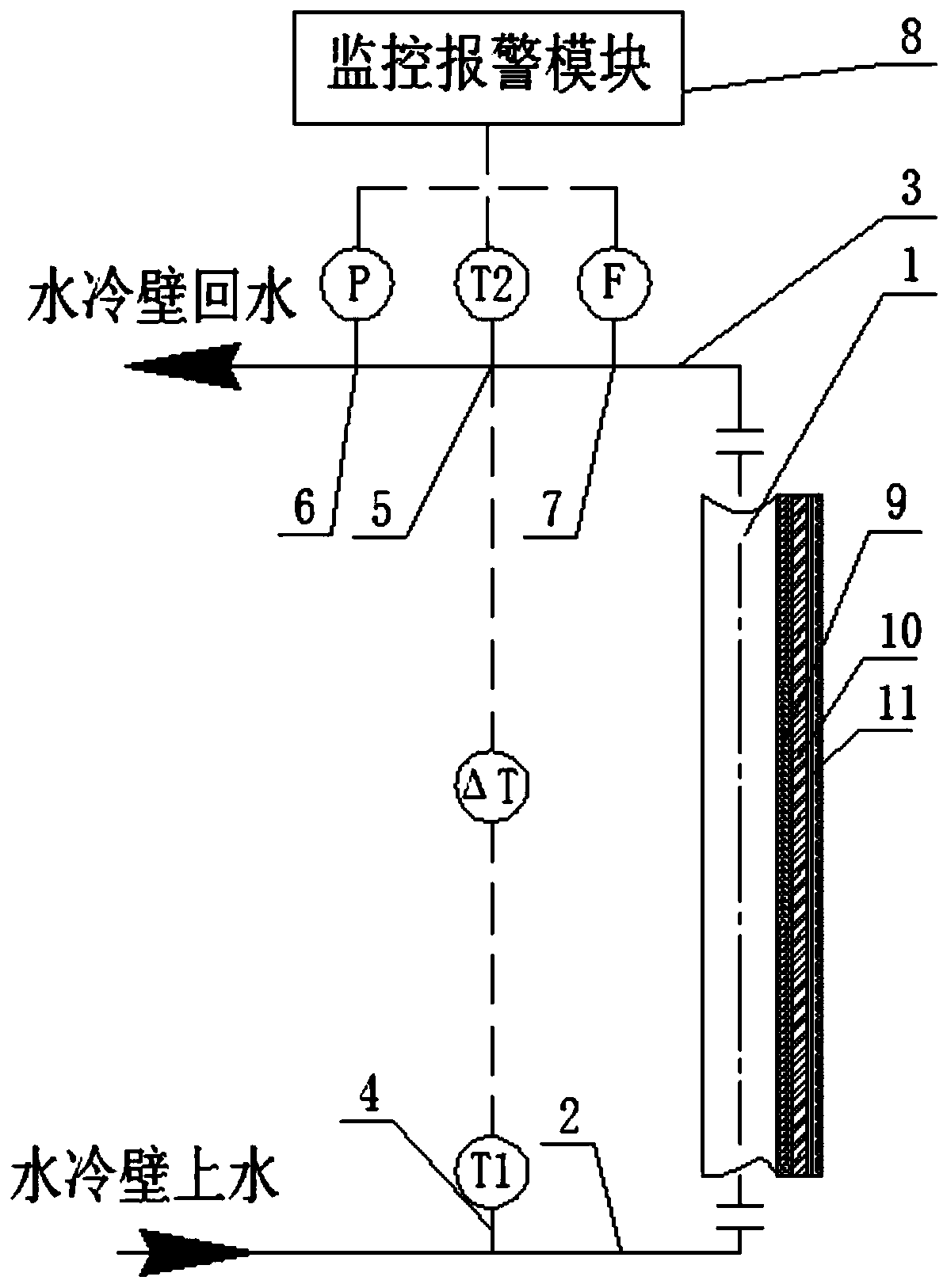

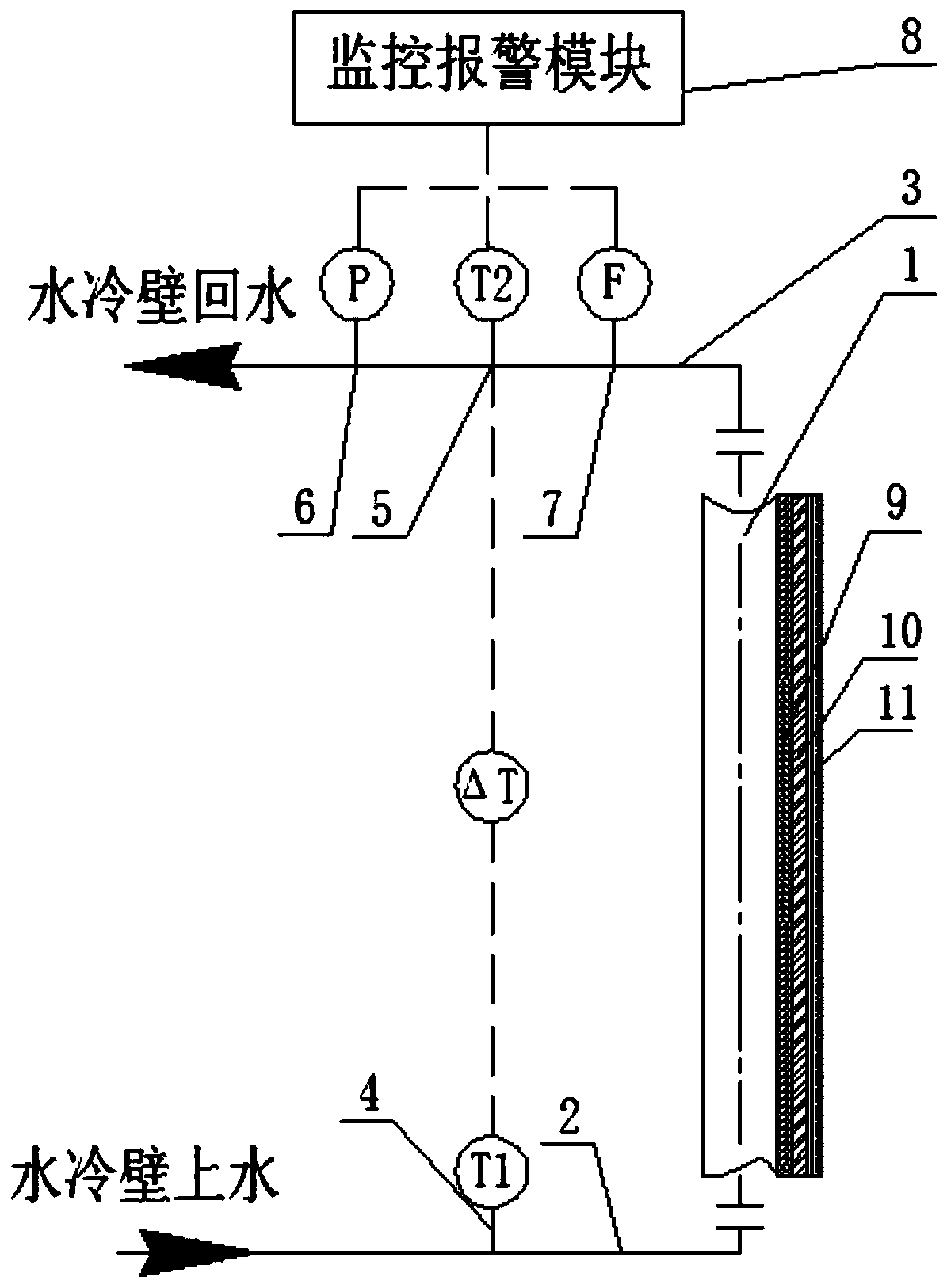

[0029] Refer to attached figure 1 , the present invention provides a water wall safety monitoring device for a gasification furnace, comprising a water wall pipe 1, a water wall pipe upper water interface 2, a water wall pipe return water interface 3, a water wall water temperature measuring point 4, and a water wall return water Temperature measuring point 5, water wall backwater pressure measuring point 6, water wall pipe flow measuring point 7 and monitoring and alarm module 8. The fire-facing side of the water-cooled wall tube 1 is covered with a refractory lining 9, and a fixed slag layer 10 and a flowing slag film 11 will be formed on the surface of the refractory lining 9 during stable operation.

[0030] The water-cooled wall tube 1 is the basic unit of the water-cooled wall of the gasifier, which can be a coil type, column-type or other special-shaped structure, or can be a local heat exchange surface of the water-cooled wall formed by a plurality of steel pipes passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com