A poy wire cooling device and cooling process thereof

A technology of cooling device and cooling block, which is applied in filament/thread forming, textile and paper making, fiber processing, etc. It can solve problems affecting the quality of POY filaments, improve cooling forming effect, improve heat exchange efficiency, and increase contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

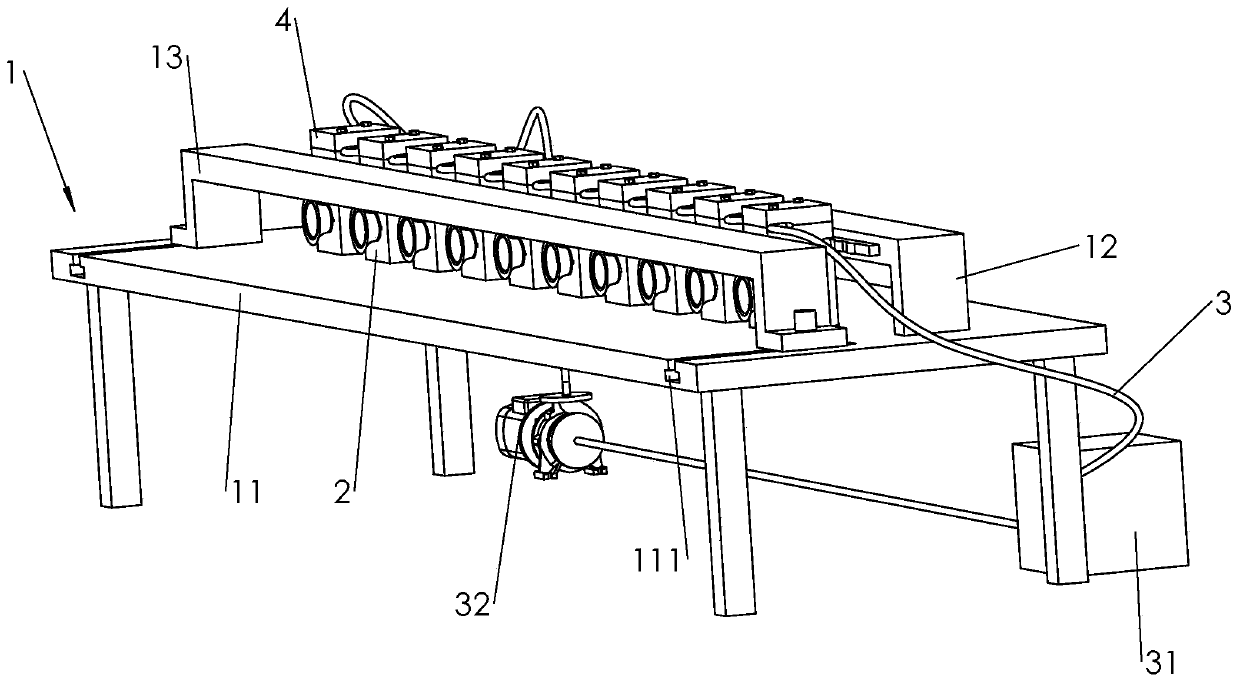

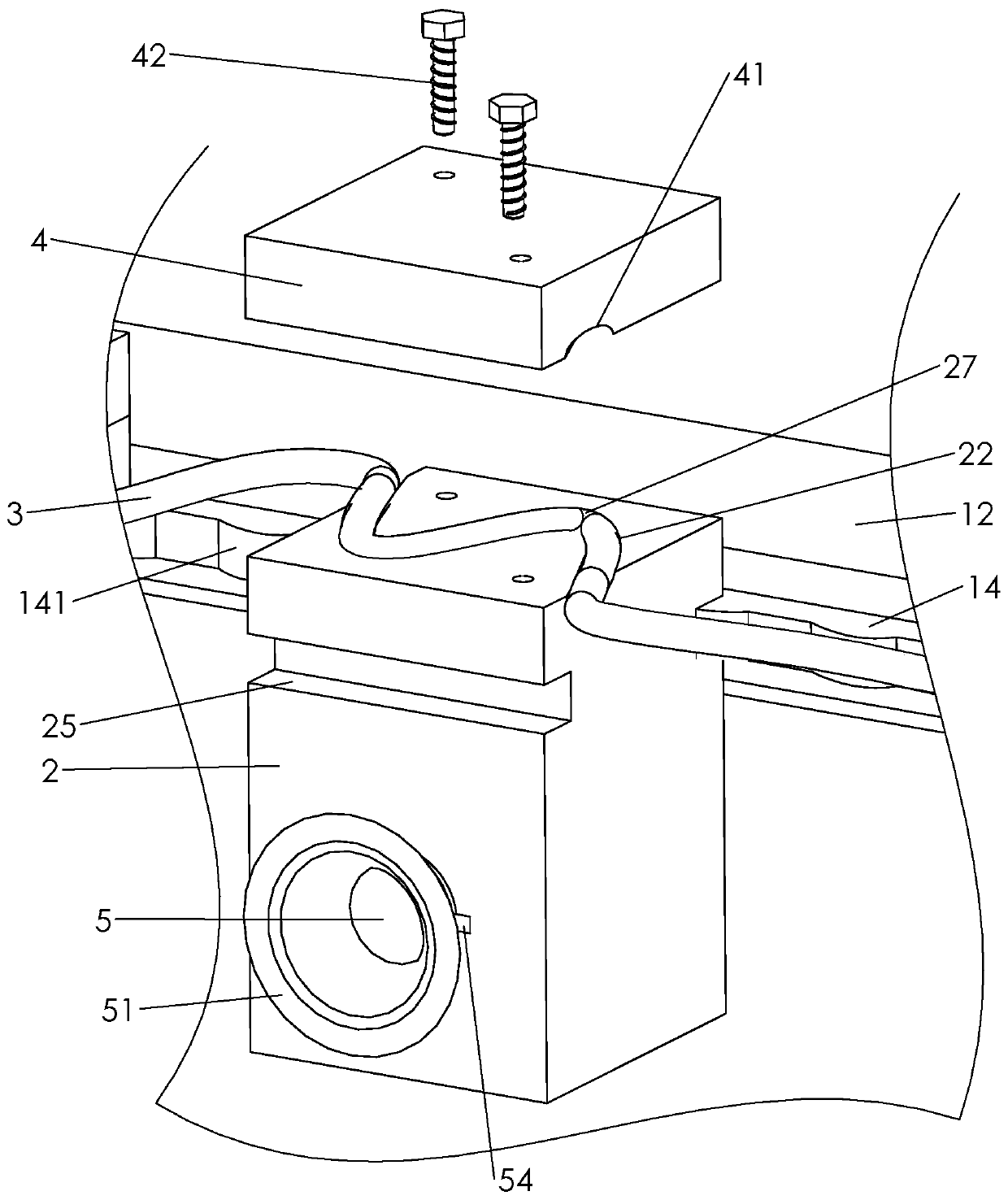

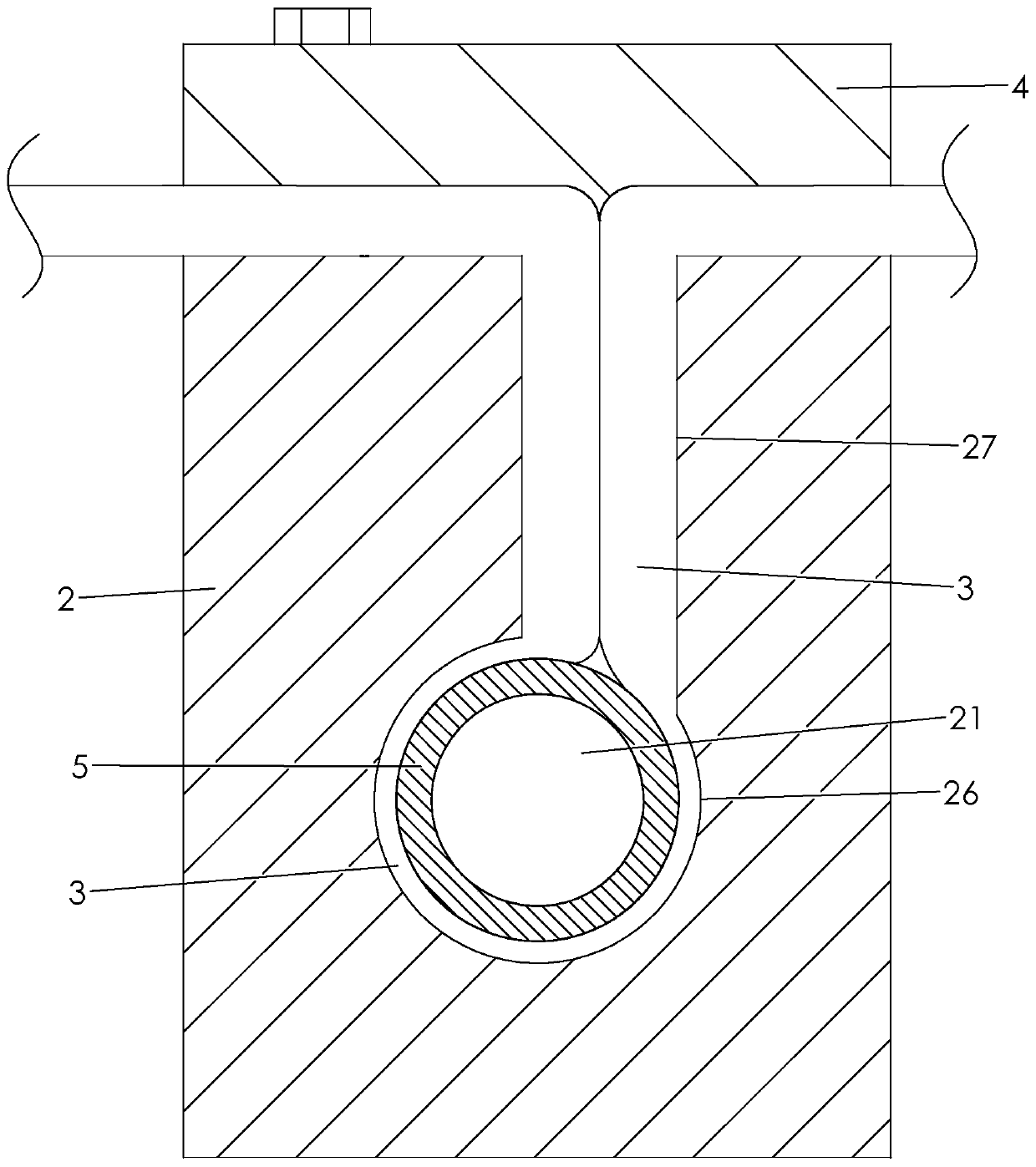

[0039] Embodiment one: if figure 1 with figure 2 As shown, a POY filament cooling device and its cooling process include a mounting frame 1 arranged on the discharge side of a screw extrusion spinning machine, and a plurality of heat conduction cooling blocks 2 are arranged on the mounting frame 1 . Such as Figure 4 As shown, an insertion slot 28 is provided on the side wall of the heat conduction cooling block 2, and a heat conduction cooling jacket 5 is inserted in the insertion slot 28, and a tow channel 21 for a single tow to pass through is provided on the heat conduction cooling jacket 5 . The tow channel not only has a certain shaping effect on the tow, so that the tow is not easy to be deformed, but also makes the tow not easy to be bonded to each other.

[0040] Both the heat conduction cooling block 2 and the heat conduction cooling jacket 5 are made of inorganic non-metallic materials, such as beryllium oxide ceramics. The thermal conductivity of beryllium oxid...

Embodiment 2

[0059] Embodiment 2: A cooling process of a POY wire cooling device, including primary cooling, using a heat-conducting cooling jacket 5 made of inorganic non-metallic materials to conduct heat conduction on the tow, and then using 3 cooling hoses containing flowing fluid to conduct heat conduction. Contact cooling is carried out by the heat conduction cooling jacket 5;

[0060] For secondary cooling, use the heat conduction cooling block 2 made of inorganic non-metallic materials to conduct heat conduction on the heat conduction cooling jacket 5 in the primary cooling, and then use the cooling hose 3 containing flowing fluid to conduct contact cooling on the heat conduction cooling block 2;

[0061] For third cooling, use another compacted cooling block 4 made of inorganic non-metallic material to conduct heat conduction to the heat conduction cooling block 2 in the secondary cooling, and then use the cooling hose 3 containing flowing fluid to compress the cooling block 4 Per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com