Combustor capable of introducing air from top

A burner and gas mixing technology, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve problems such as insufficient premixing of mixed gas, troublesome cleaning, nozzle clogging, etc., and achieve the effect of enhancing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

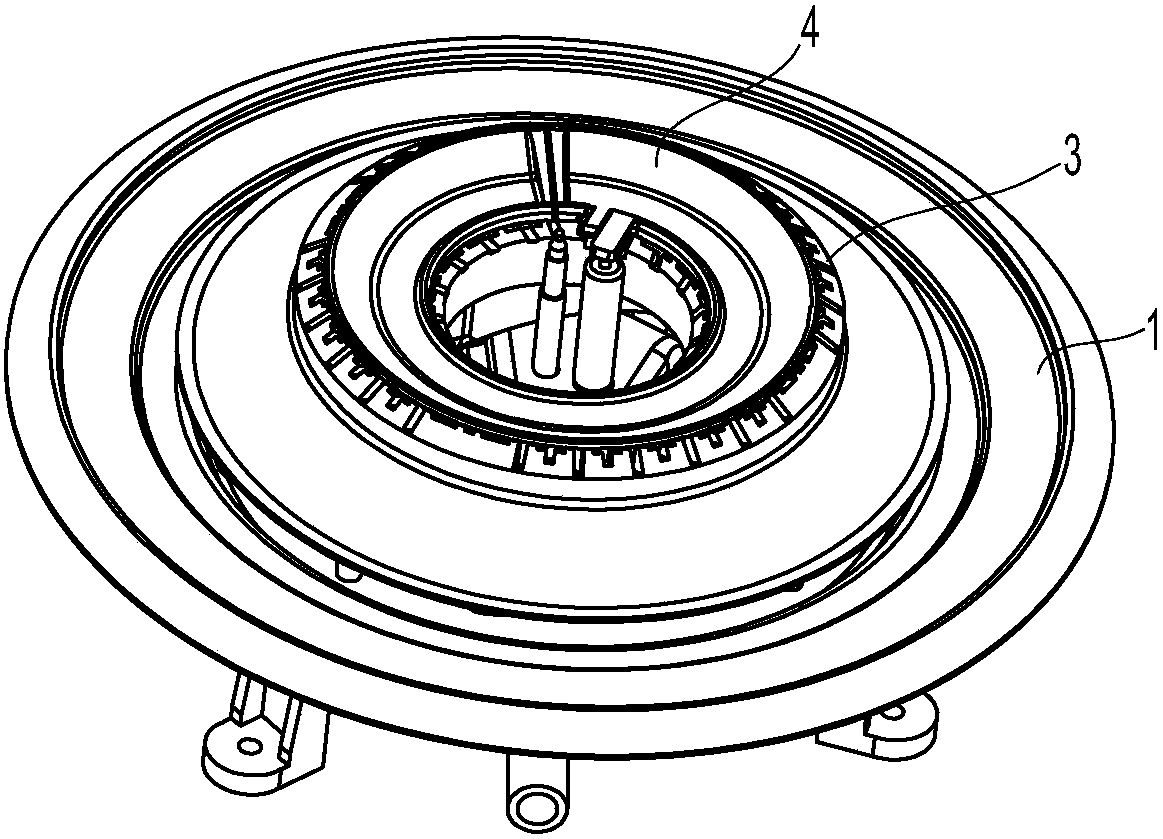

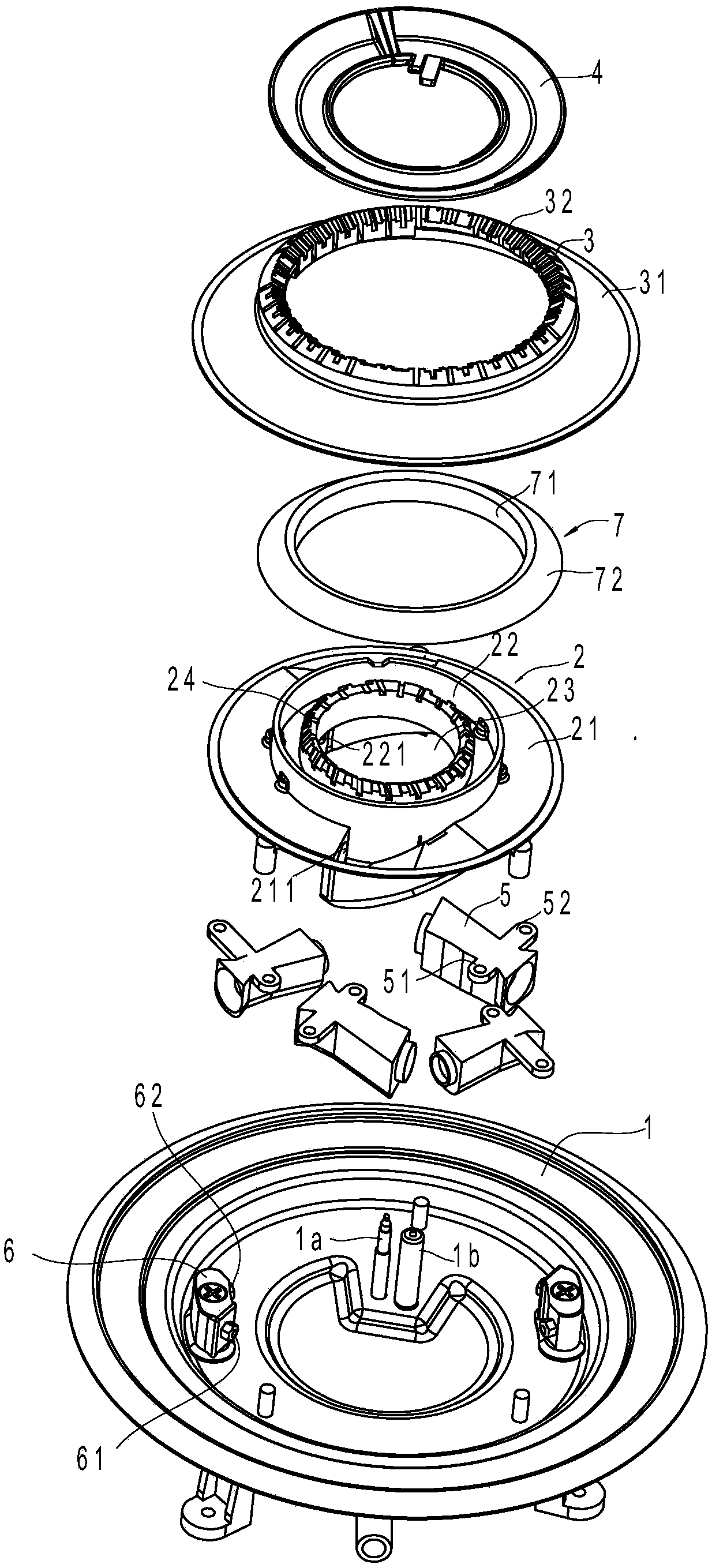

[0032] Example 1, such as figure 1 and figure 2 As shown, the burner in this embodiment includes a liquid pan 1, an air mixing seat 2 and a fire cover. The liquid pan 1 is provided with two separately arranged nozzle seats 6, and each nozzle seat 6 has a first nozzle 61 And the second nozzle 62; the liquid pan 1 is provided with a thermocouple 1a and an ignition needle 1b.

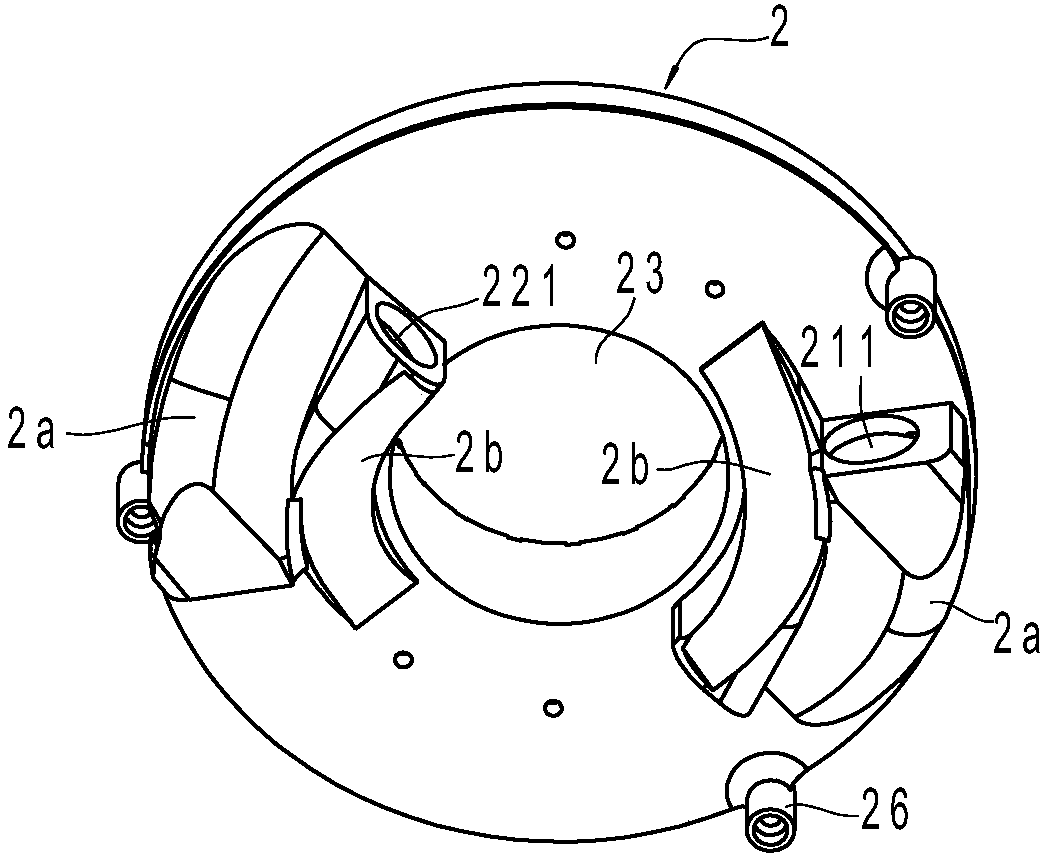

[0033] The air mixing seat 2 is arranged on the upper end surface of the liquid holding tray 1, and the upper end surface of the air mixing seat 2 has an annular inner air mixing groove 22 and an outer air mixing groove 21 positioned outside the inner air mixing groove 22, and the inner air mixing groove 22 has at least Two inner air inlets 221 are opened, and two outer air inlets 211 are opened on the outer air mixing tank 21. The lower end surface of the air mixing seat 2 is provided with two laterally arranged inner injection pipes and two laterally arranged The outer injection tube of the inner inje...

Embodiment 2

[0047] Example 2, such as Figure 6 and Figure 7 As shown, the air blocking ring 7 in this embodiment is integrally formed inside the outer air mixing groove. The end of the gas retaining ring 7 is bent upwards to form a liquid holding ring groove 73. After the soup enters the gas mixing seat 2, it is accumulated in the liquid holding ring groove 73, preventing the soup from further entering the external gas mixing tank and the external suction. When there is too much liquid in the injection tube, just remove the first fire cover and clean the accumulated liquid. Refer to Example 1 for other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com