Interstage rotary detonation variable cycle turboshaft engine

A turboshaft engine and variable cycle technology, which is applied to engine components, machine/engine, engine cooling, etc., can solve the problems of low kerosene activity and difficulty in direct detonation, and achieve the effect of reducing design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

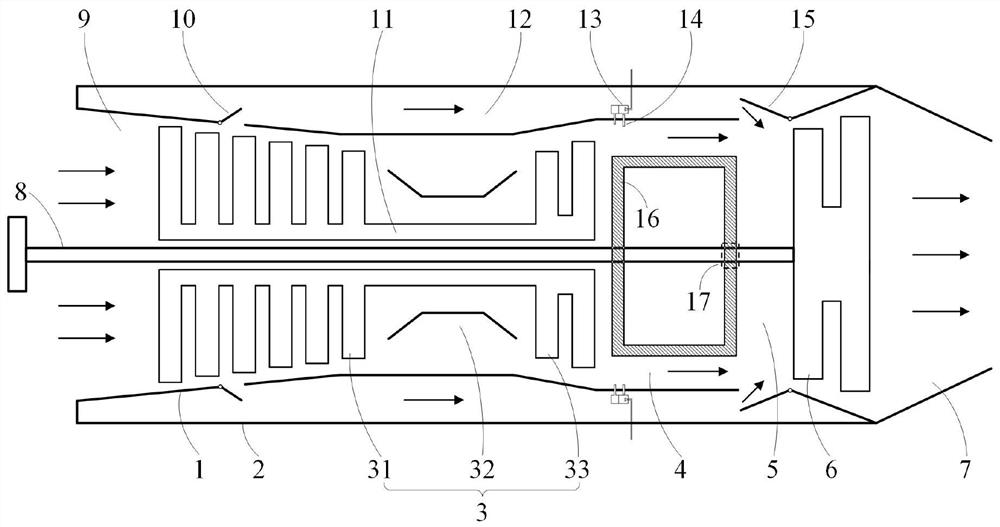

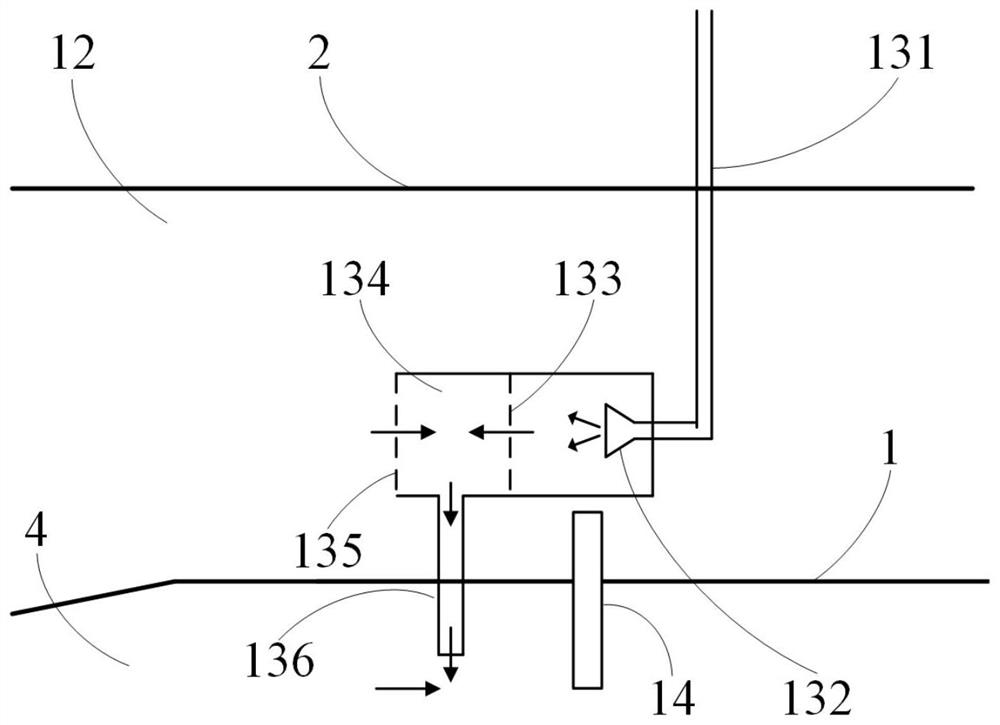

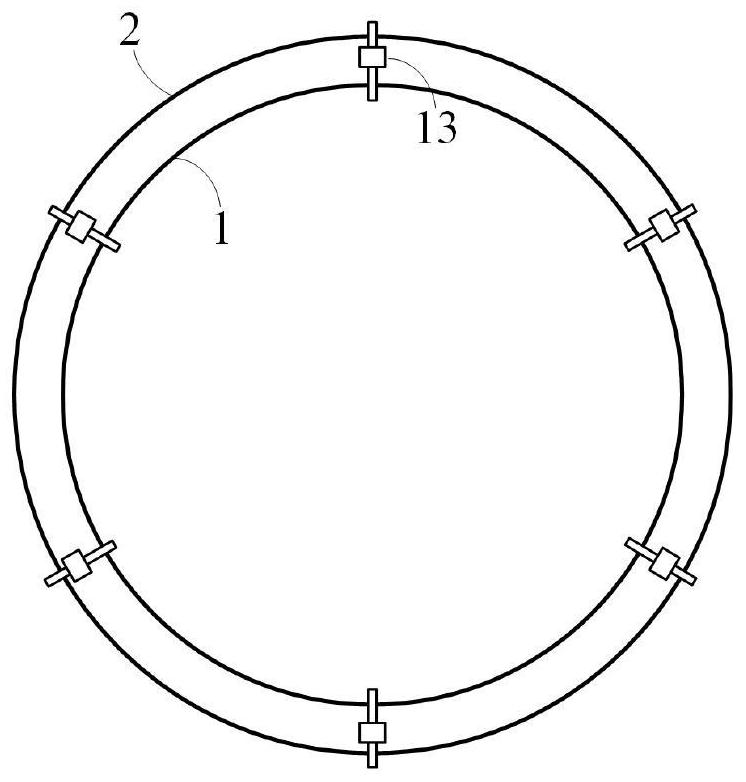

[0029] Such as figure 1 As shown, this embodiment includes an inner casing 1 , an outer casing 2 , a power shaft 8 , a core machine 3 , a central chamber 16 , a power turbine 6 , a splitter plate, an oil circuit assembly 13 , and an igniter 14 .

[0030] The inside of the inner casing 1 is provided with a core machine 3, a central chamber 16 and a power turbine 6 in sequence from front to back; Output Power.

[0031] The core engine 3 includes a compressor 31 , an isobaric combustion chamber 32 and a gas turbine 33 , wherein the compressor 31 and the gas turbine 33 are connected by a high-pressure rotor shaft 11 and rotate synchronously.

[0032] A cooling flow path 12 is formed between the inner casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com