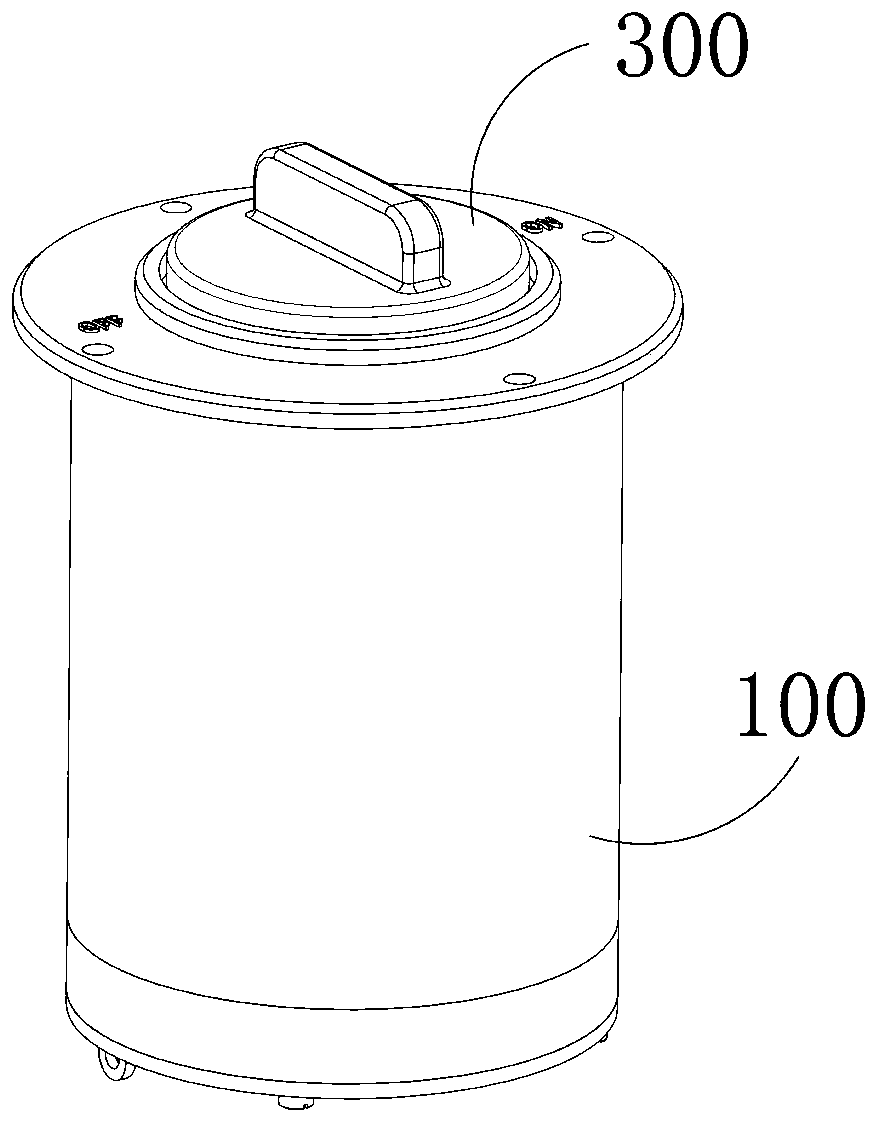

Safety controller applied to circuit overload protection

A safety controller and overload protection technology, applied in the field of circuits, can solve problems such as the failure of the protection switch to work normally, the bouncing fatigue of the bimetal strip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

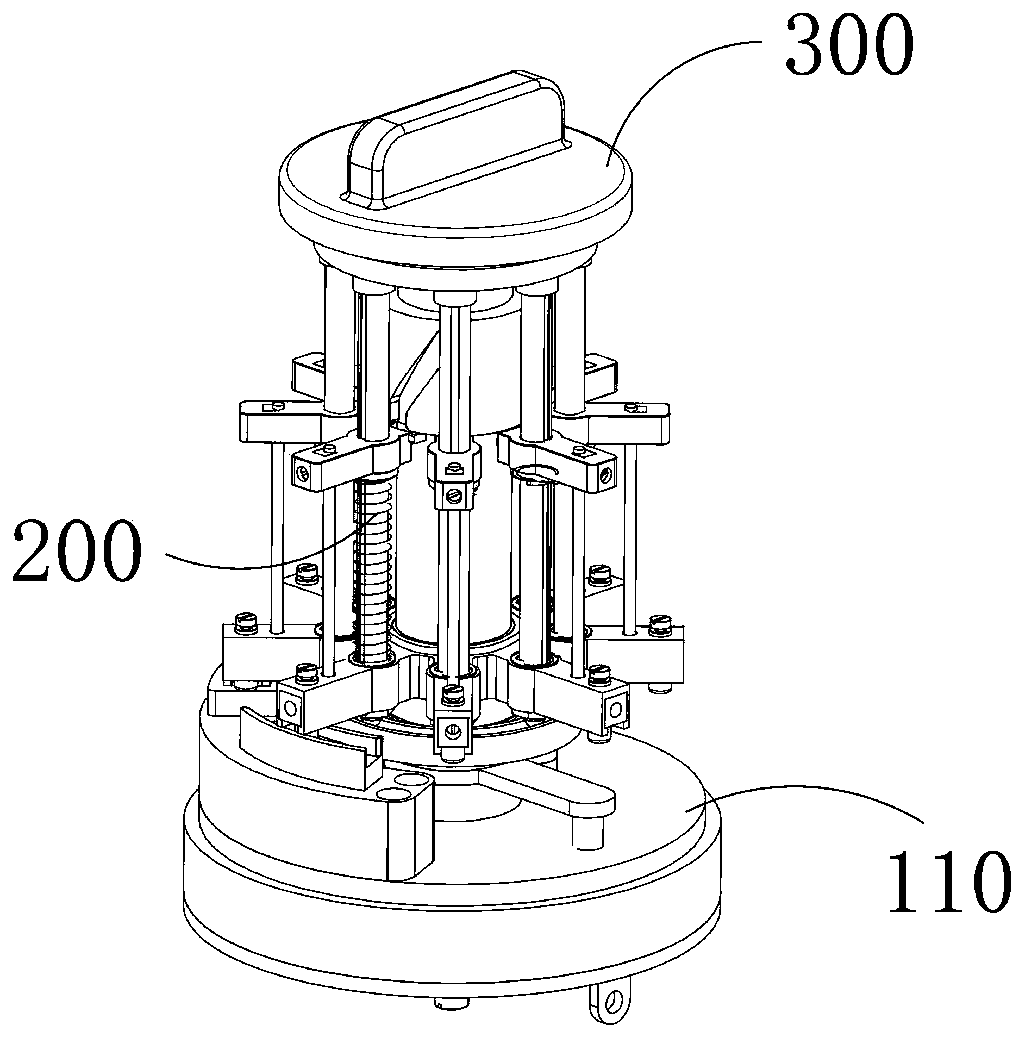

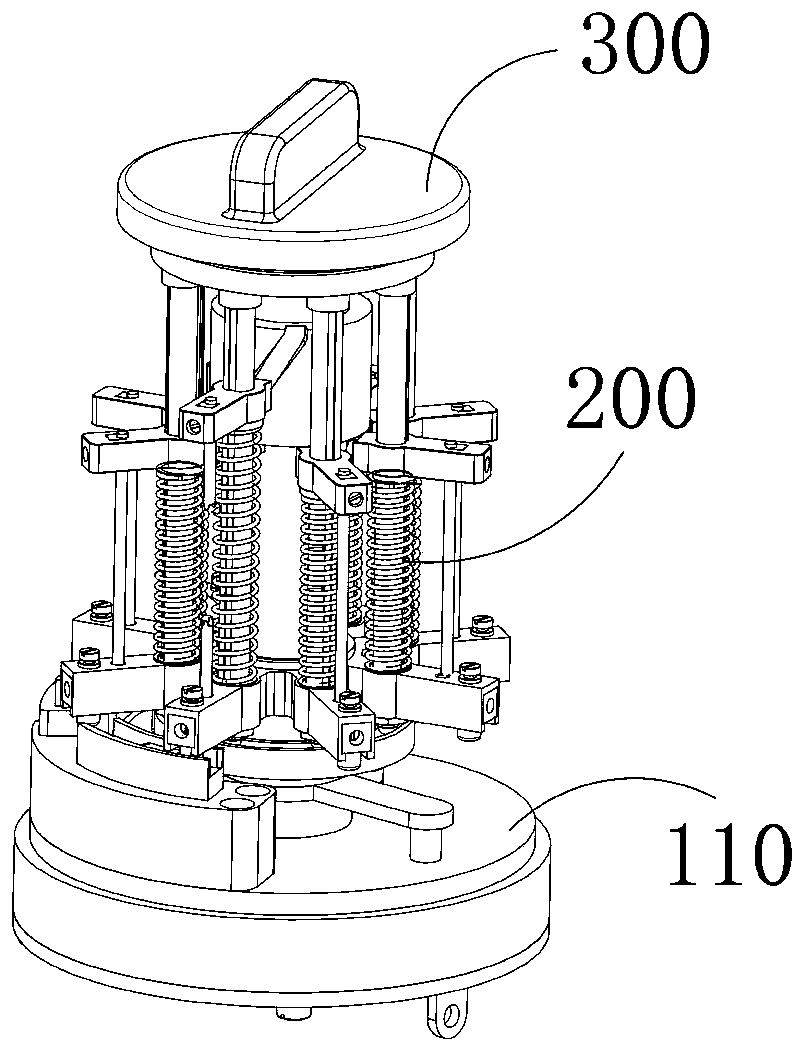

[0070] The advantage of using the circuit protection device and the knob reset device to cooperate with the opening and closing of the corresponding electrical equipment in the present invention is that when the circuit does not have an abnormal failure, the user can turn the knob switch manually / reversely to turn the knob switch on / off Moreover, the circuit protection device is still during this process. When an abnormal fault occurs in the circuit, the circuit protection device can automatically replace the melt inside itself and automatically turn off the knob switch, effectively preventing the circuit from being damaged, and the safety performance is better. At the same time, the setting of the rolling parts in the protection mechanism converts the friction mode between the conductive column and the conductive plate from sliding friction to rolling friction, avoiding the occurrence of poor contact between the conductive column and the conductive plate due to friction In add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com