Blue light-blocking soft contact lens, and method for manufacturing same

A soft contact lens, contact lens technology, applied in glasses/goggles, optics, optical components, etc., can solve the problems of blue light blocking efficiency decrease, contact lens exudation, and light transmittance reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of the soft contact lens for blocking blue light of the present invention comprises the following steps:

[0042] The step of preparing a contact lens composition comprising a hydrophilic acrylate monomer, a crosslinking agent, and an initiator;

[0043] The step of adding a specific compound having the following chemical structural formula (1) or chemical structural formula (2) in the above-mentioned contact lens composition;

[0044] A step of injecting the composition into a mold for forming a contact lens;

[0045] a step of heat-treating the contact lens molding mold injected with the composition;

[0046] the step of separating the shaped contact lens from the mold;

[0047] The steps of wetting and disinfecting the contact lens;

[0048] The step of packing and sterilizing the contact lens.

[0049]The hydrophilic acrylate monomer can be used in one or more hydrophilic monomers such as 2-hydroxyethyl methacrylate, N-vinylpyrrolidone, N,...

Embodiment 1

[0064] The chemical structural formula (2) is 2-{4-[(E)-phenylazo]phenoxy}ethyl-2-acrylate (2-{4-[(E)-phenyldiazenyl]phenoxy}ethyl- 2-acrylate).

[0065] 96.8 parts by weight of 2-hydroxyethyl methacrylate as a hydrophilic acrylate monomer, 1 part by weight of ethylene glycol dimethacrylate as a crosslinking agent, and 2,2'-azo After 0.2 parts by weight of diisobutyronitrile are uniformly mixed, add the specific compound 4-[(E)-phenylazo]phenyl-2-acrylate methyl ester (4-[(E)- phenyldiazenyl] phenyl-2-methacrylate) 2 parts by weight, stirred at room temperature for 30 minutes, so that it was uniformly dissolved, and a soft contact lens composition with blue light blocking function was prepared.

[0066] After pouring the above prepared composition into the mold made of polypropylene made by our company, heat treatment is carried out at 60°C for 8 hours, and at 120°C for 4 hours to complete the cross-linking of the composition. Sodium chloride 0.9% by weight saline is immerse...

Embodiment 2

[0068] 88.3 parts by weight of 2-hydroxyethyl methacrylate as a hydrophilic acrylate monomer, 10 parts by weight of N-vinylpyrrolidone, 1 part by weight of ethylene glycol dimethacrylate as a crosslinking agent, and as an initiator After uniform mixing of 0.2 parts by weight of 2,2'-azobisisobutyronitrile, the specific compound 2-{4-[(E)-phenylazo]phenoxy}ethane with chemical structural formula (2) was added Base-2-acrylate (2-{4-[(E)-phenyldiazenyl]phenoxy}ethyl-2-acrylate) 0.5 parts by weight, stirred at room temperature for 30 minutes, dissolved evenly, and prepared a soft Sexual contact lens composition.

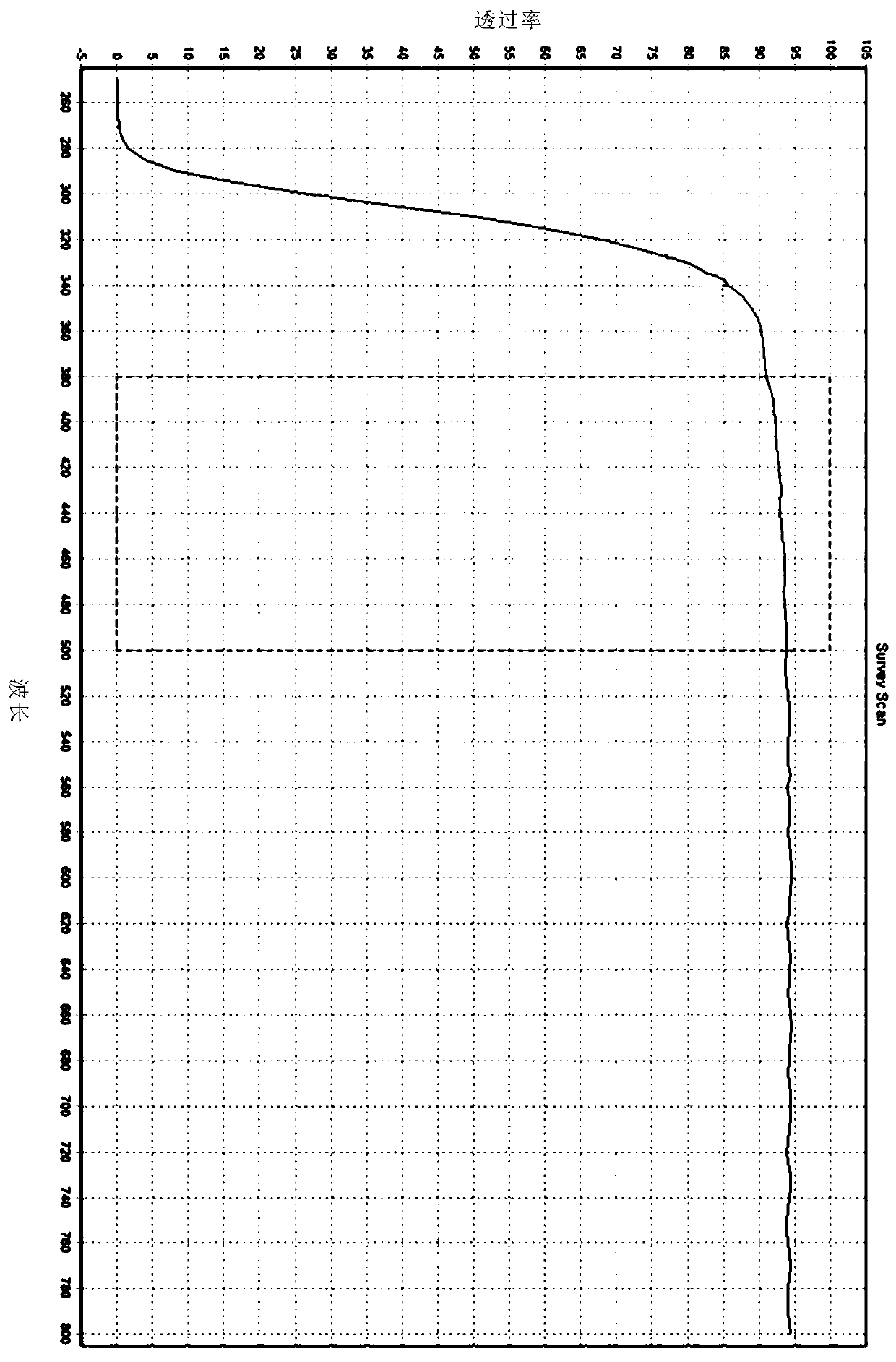

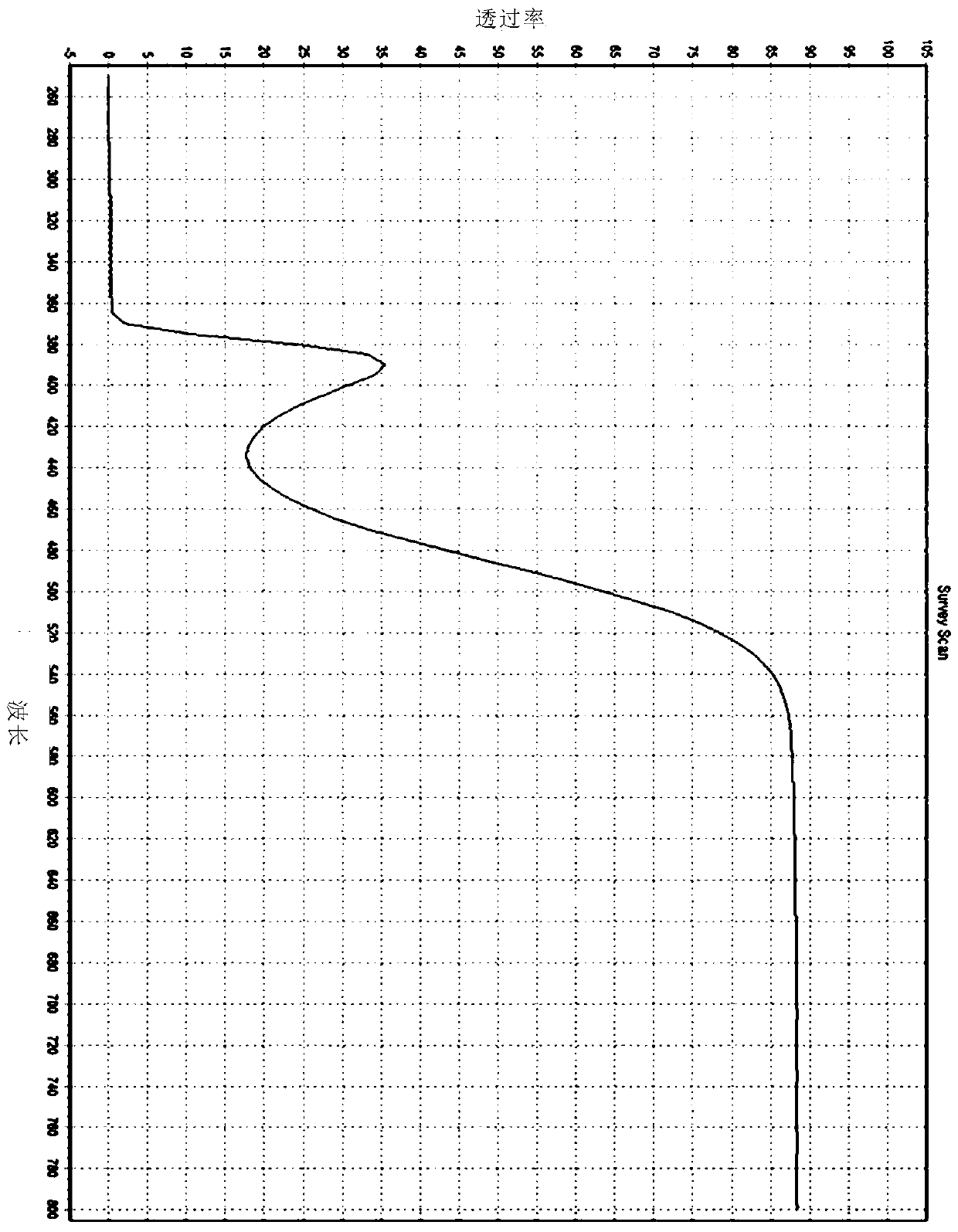

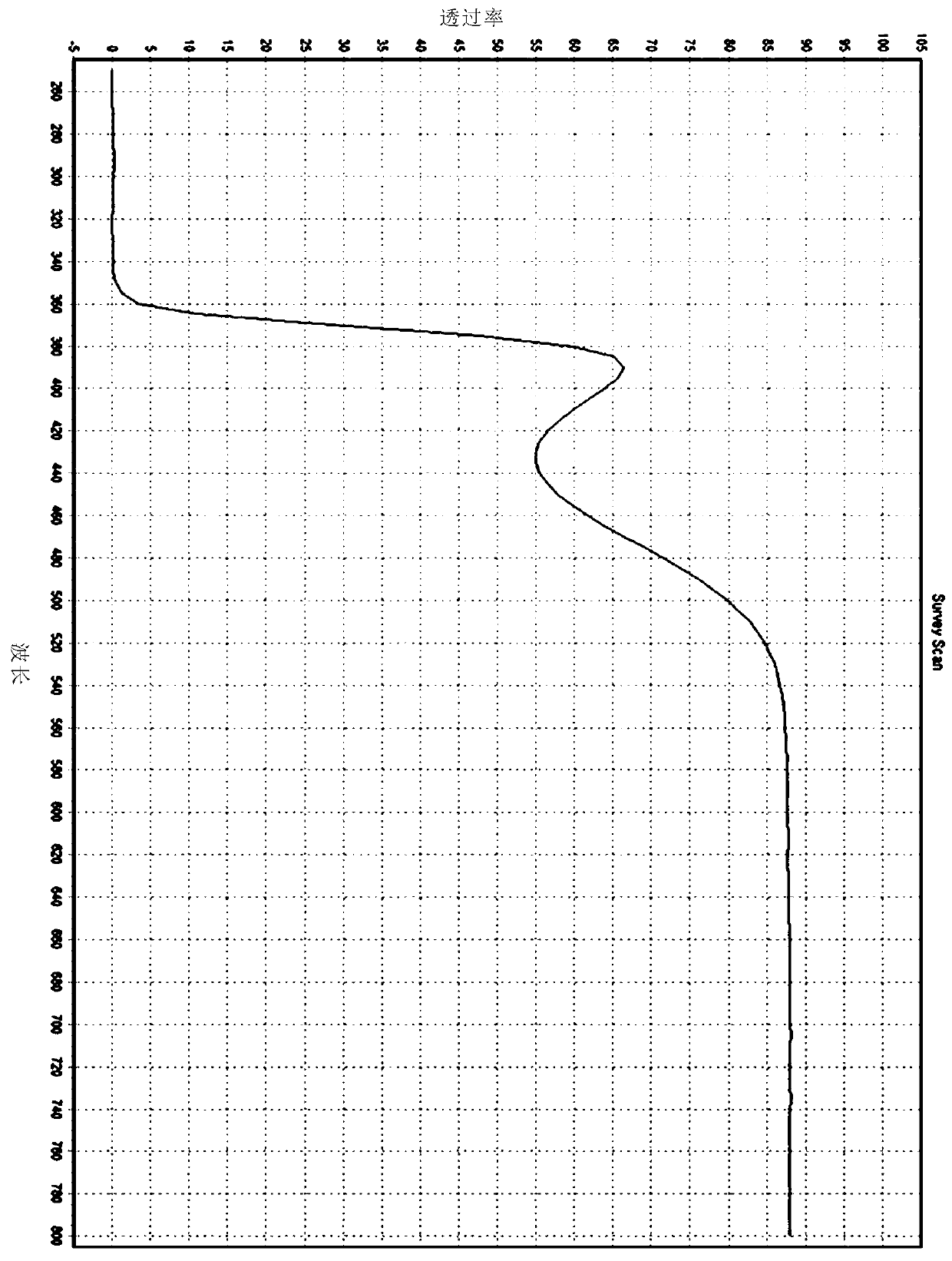

[0069] Then, the manufacture of contact lenses is carried out in the same manner as in Example 1. For the soft contact lenses with the function of blocking blue light manufactured in the above steps, the transmittance in the ultraviolet and visible light regions is measured, and the following results are obtained: image 3 As shown in the spectral distribution curve, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com