Ultrathin ceramic filter plate, preparation method thereof and filter with ultrathin ceramic filter plate

A ceramic filter plate, filter plate technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of excessive thickness of ceramic filter plate, high labor intensity of transportation, insufficient structural strength, etc., to improve structural strength , Reduce maintenance cost and maintenance difficulty, convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

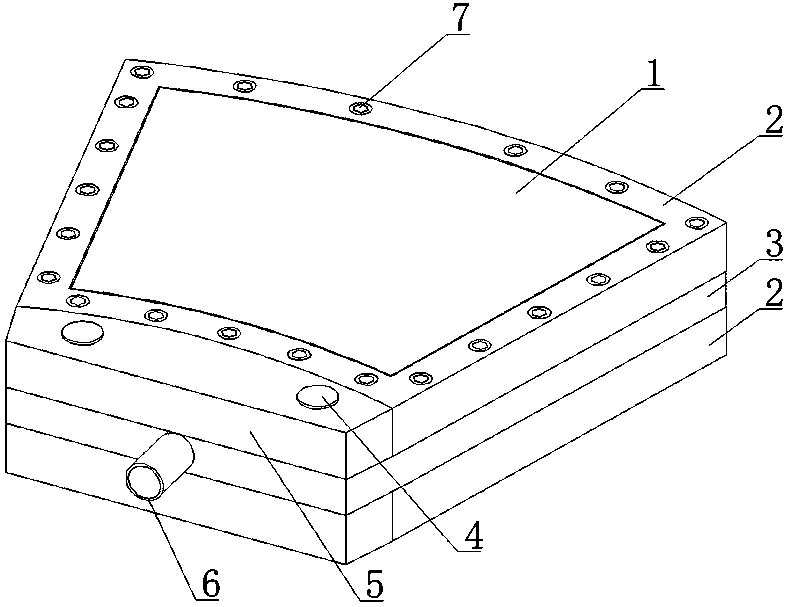

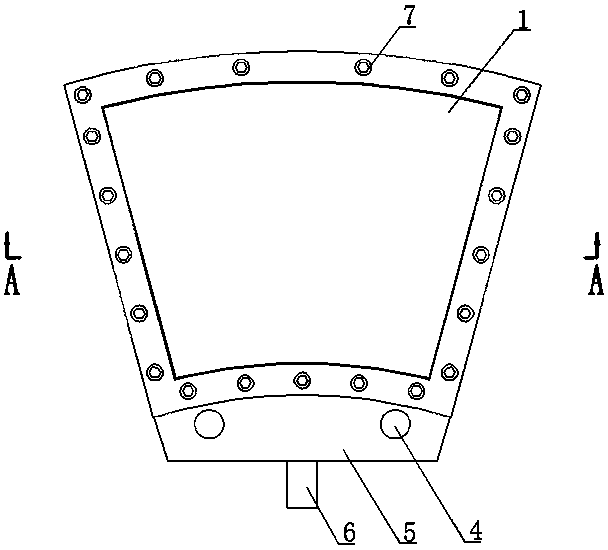

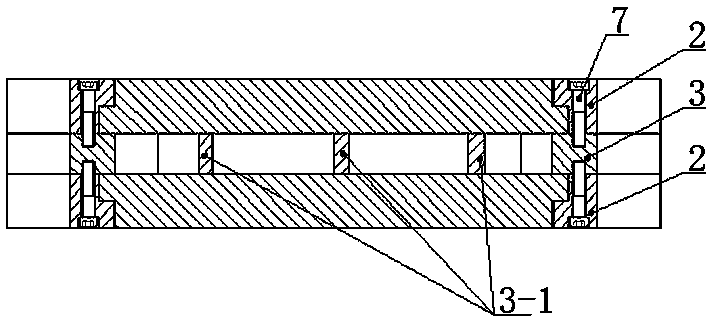

[0041] An ultra-thin ceramic filter plate, which includes a support plate 3 in the middle, filter veneers 1 located on both sides of the support plate 3, reinforcement strips 2, outlet pipes 6, and bases located on both sides of the end of the support plate 3 5 and the positioning seat 4, the positioning seat 4 is installed on the base 5, the base 5, the water outlet pipe 6 and the support plate 3 are integrally injection molded, and the support plate 3 is provided with three holes with the same thickness as the support plate 3 The support frame 3-1, between two support frames 3-1 is a hollowed-out water separation cavity 3-2, the support frame 3-1 is set as a strip structure, and one end of the support frame 3-1 is connected with the support plate 3 edges are connected, and the other end is suspended in the air. The support plate 3 and the support frame 3-1 are integrally injection-molded, and the structural strength of the support plate 3 is improved by setting the strip-shap...

experiment example 1

[0048] Experimental example 1 is the filter plate prepared by the embodiment, the thickness is the same as that of the comparative example, and the filter is the same as the filter of the comparative example, all of which are ordinary ceramic filters without explosion-proof plate mechanism;

experiment example 2

[0049] Experimental example 2 is the filter plate that embodiment prepares, and thickness is identical with comparative example, and filter machine is compared with the filter machine of comparative example, and experimental example 2 adopts the ceramic filter machine that increased explosion-proof plate mechanism in the embodiment;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com