A traction roller fixed-length conveying indexing mechanism

A technology of fixed-length transmission and indexing mechanism, which is applied in plant protection cover, thin material handling, gardening, etc., and can solve the problem that the bag cannot meet the positioning requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

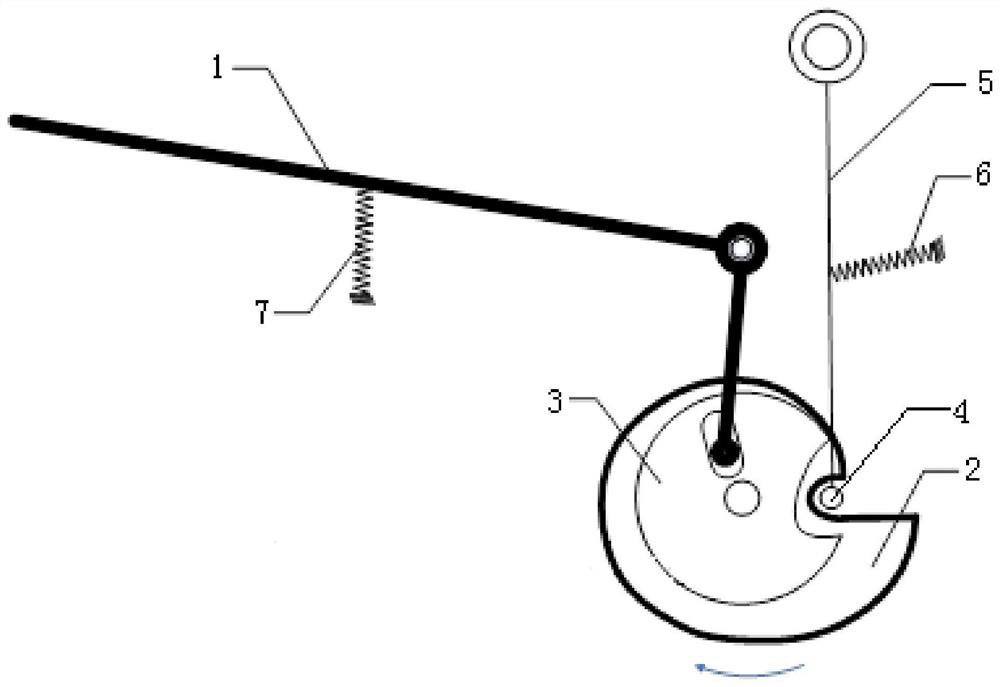

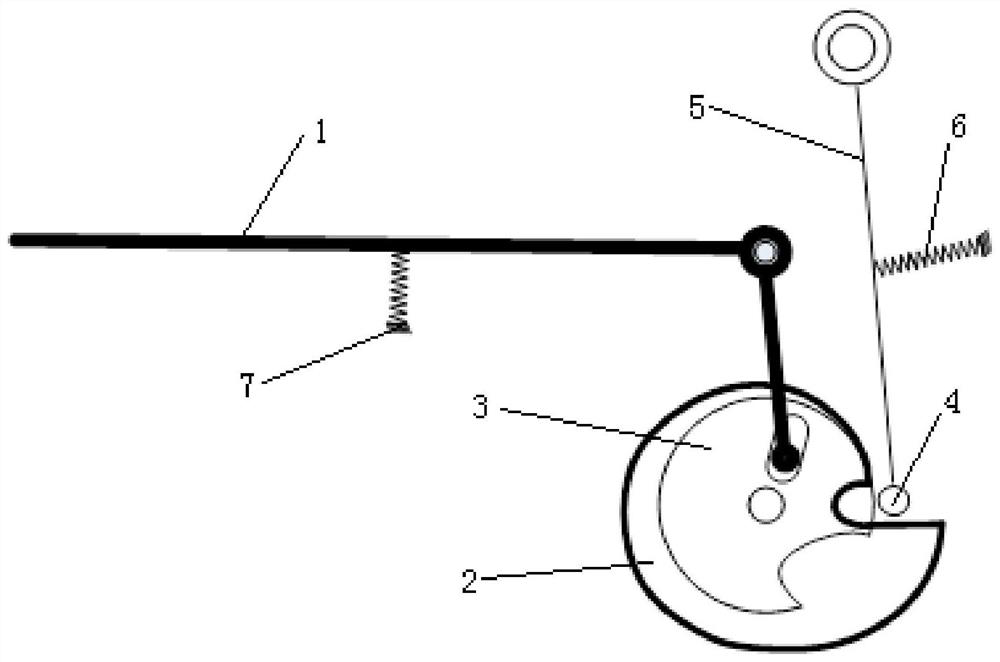

[0021] Such as figure 1 As shown, the present invention discloses a traction roller fixed-length transmission indexing mechanism, which includes a handle 1, an involute cam 2, a notch wheel 3 and a limit pin 4;

[0022] The involute starting point of the involute cam 2 has the smallest radius and the largest end point radius. The starting point of the involute is connected to one end of a U-shaped groove, the other end of the U-shaped groove is connected to one end of a straight line, and the other end of the straight line is connected to the involute line. The end point is connected, and the opening of the U-shaped groove is toward the outside of the involute cam 2.

[0023] The notch wheel 3 and the involute cam 2 are arranged coaxially, and the two move independently. The radius of the notch wheel 3 is equal to the minimum radius of the involute cam 2. A groove is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com