Counter weight block joint type taking-out type elevator counter weight device

A technology for heavy blocks and elevators, which is applied in transportation and packaging, and lifting equipment in mines. It can solve problems such as time-consuming, hurting the handling personnel, and slowing down the operation process, so as to reduce noise, speed up the maintenance process, and improve The effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

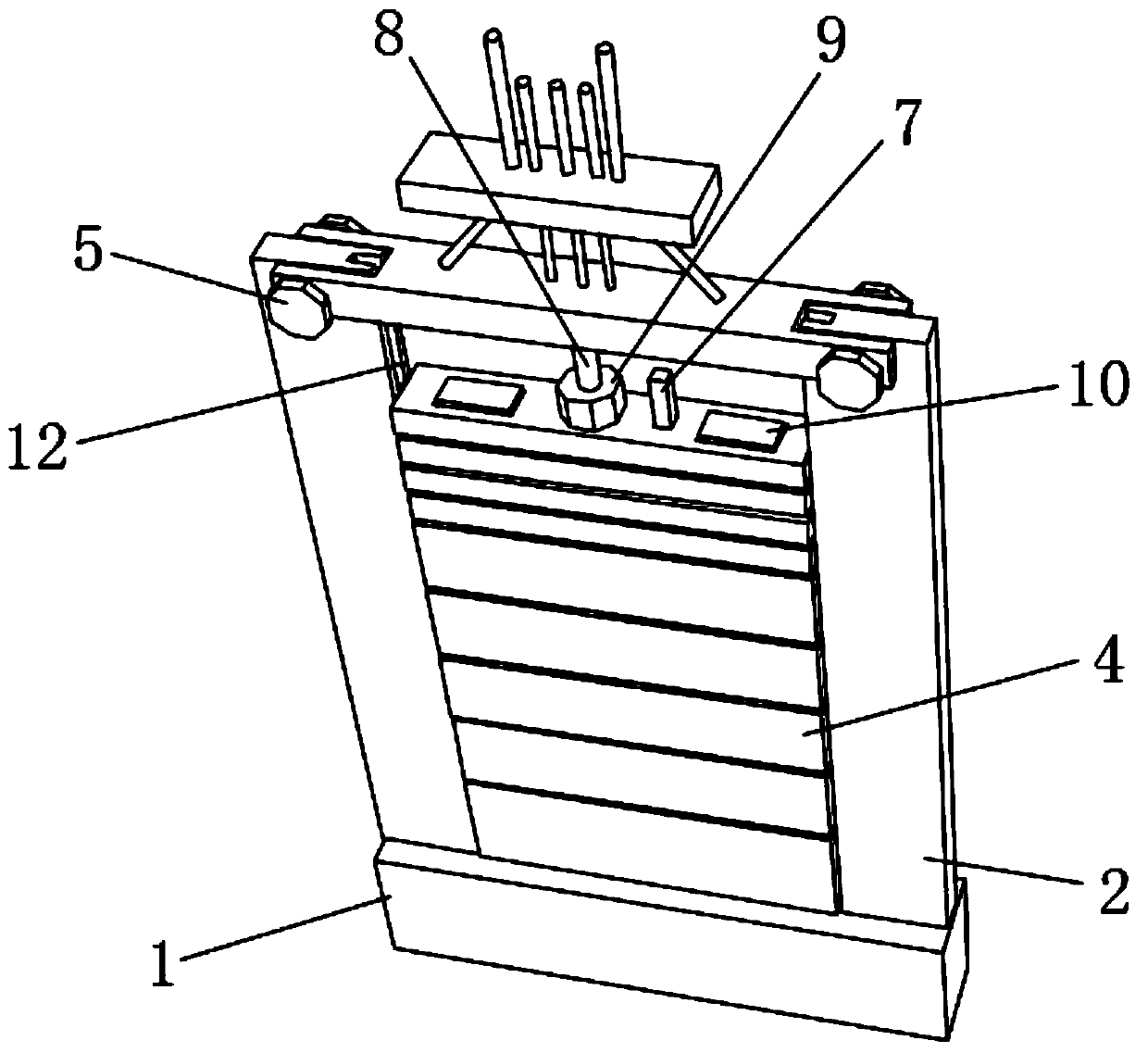

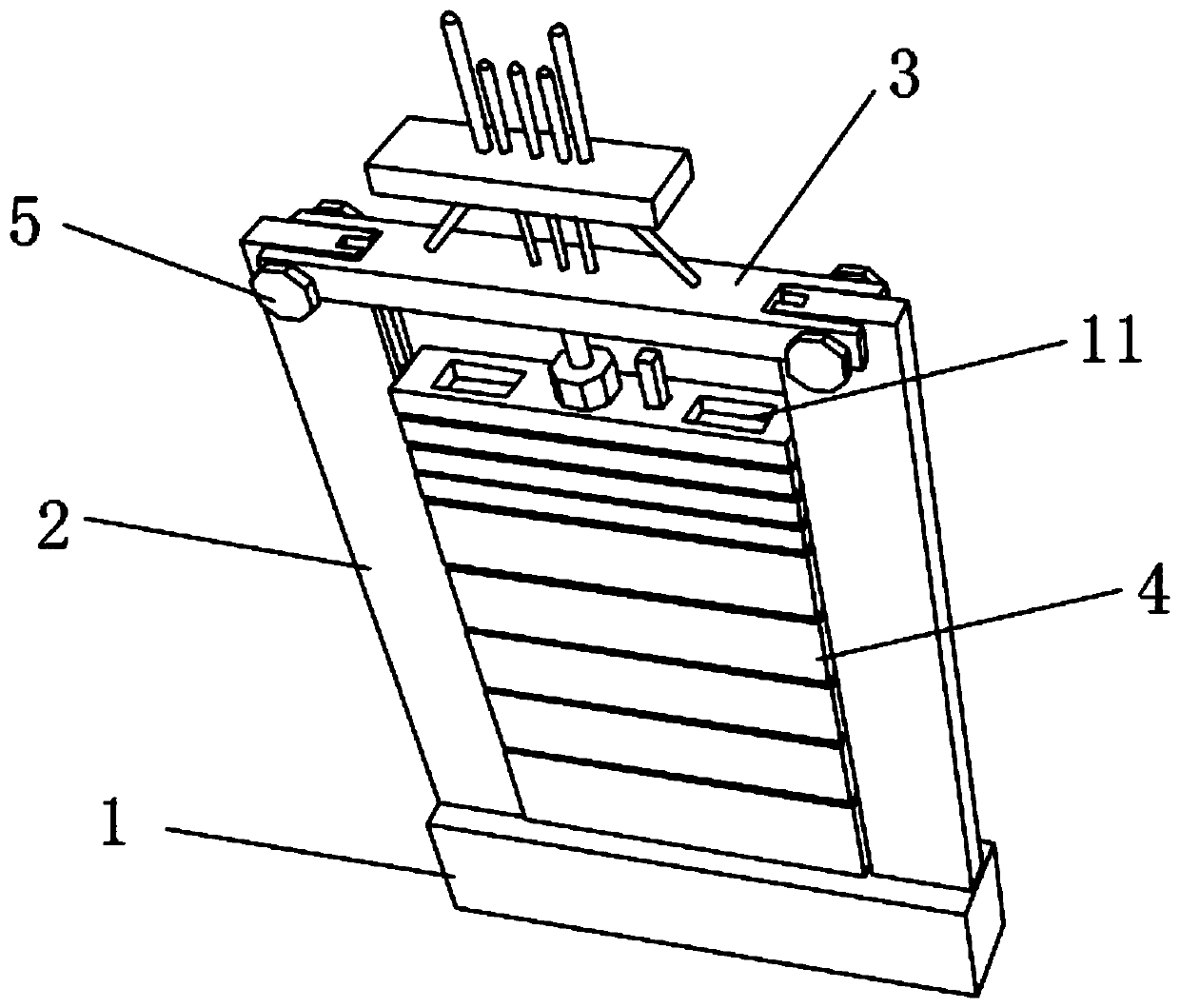

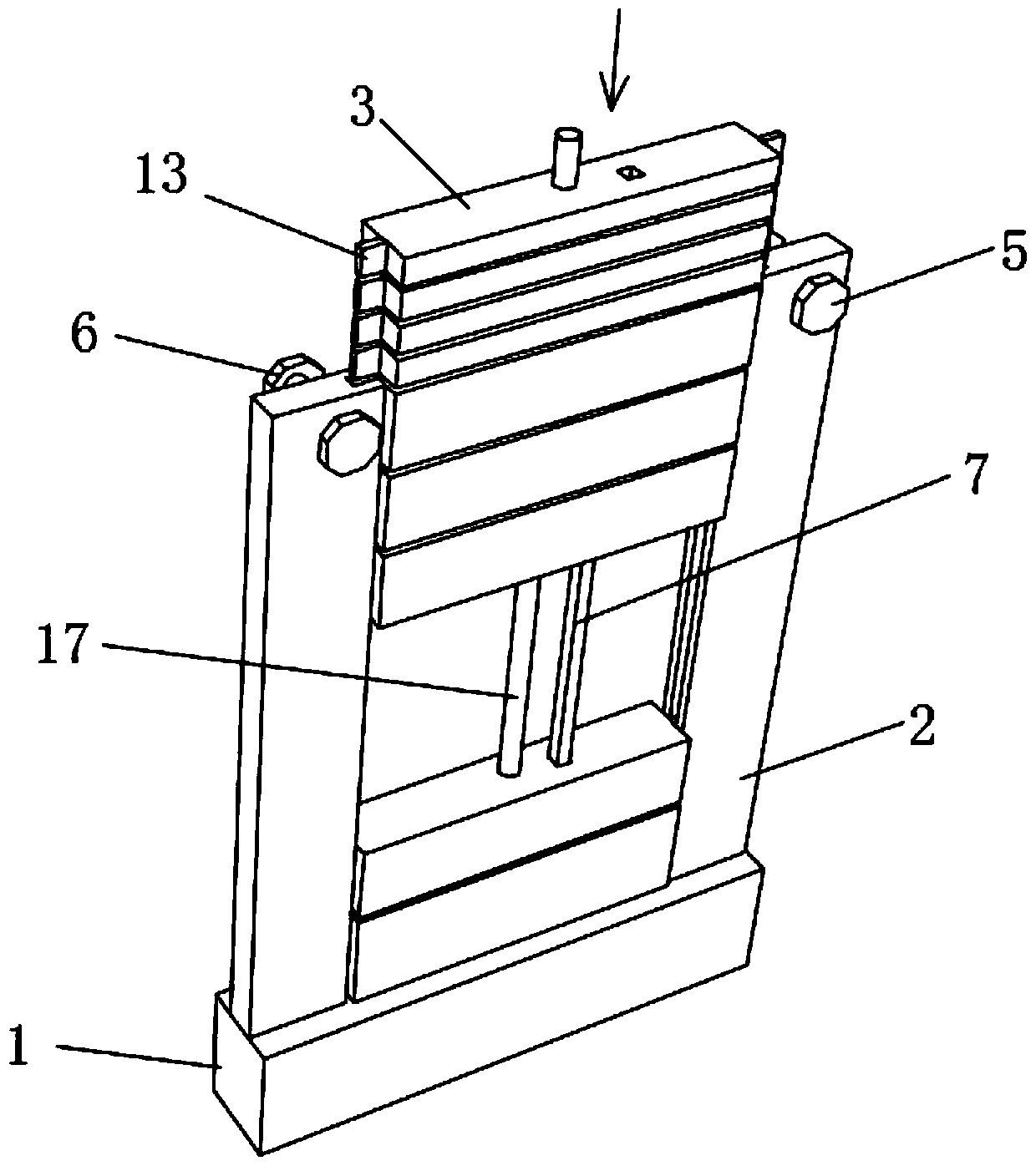

[0042] See figure 1 with figure 2 , A counterweight unit with a belt lift type elevator counterweight device, including a counterweight frame and a counterweight block group, the counterweight block group is located inside the counterweight frame, the counterweight frame includes a counterweight frame seat 1, a counterweight frame top 3 And a pair of counterweight frame edges 2, a pair of counterweight frame edges 2 are fixedly connected to the left and right ends of the upper side of the counterweight frame seat 1, and the left and right ends of the counterweight frame top 3 are cut with openings. The upper end of the side 2 of the counterweight frame matches, the left and right ends of the top 3 of the counterweight frame and the upper end of the side 2 of the counterweight frame have screw holes correspondingly, and the screw holes are threaded with fastening screws 5, and a pair of the side 2 of the counterweight frame are close to each other A vertical chute 12 is excavate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com