Active noise reduction device for electric vacuum pump of new energy vehicle

An electric vacuum pump and active noise reduction technology, which is applied to pump components, variable displacement pump components, machines/engines, etc., can solve the problems of low pertinence of noise reduction and unsatisfactory noise reduction effect, and achieve strong pertinence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

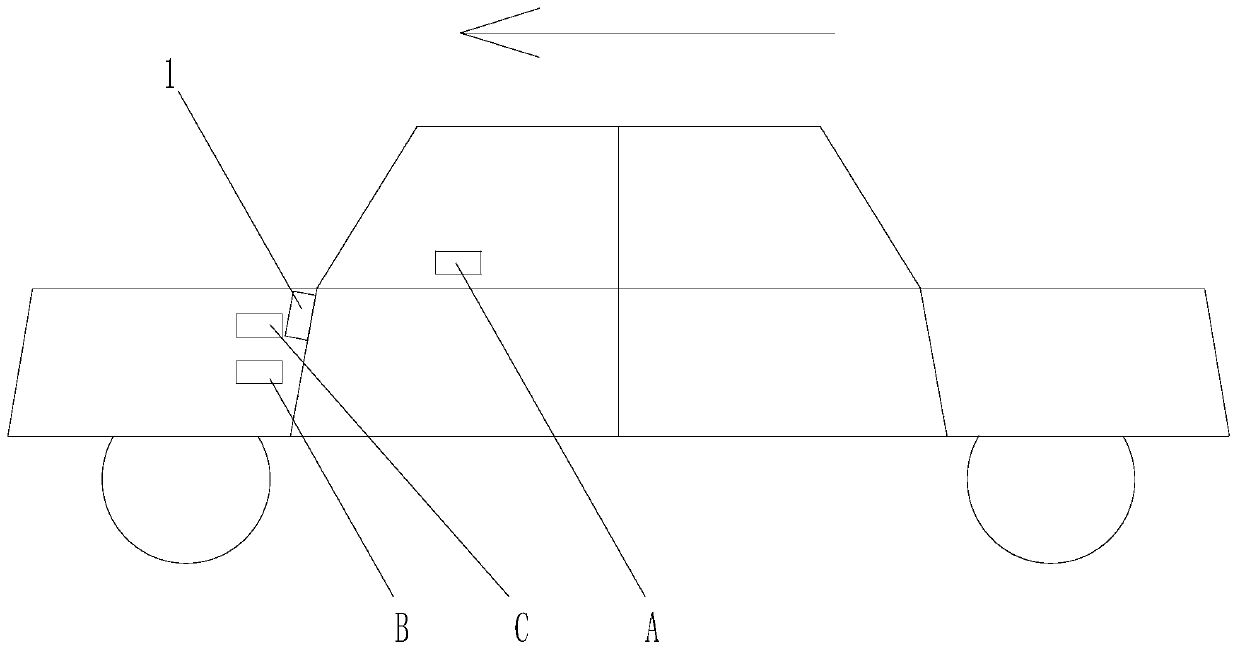

[0017] Such as figure 1 The illustrated embodiment is an active noise reduction device for an electric vacuum pump of a new energy vehicle, which is installed on a certain type of new energy vehicle.

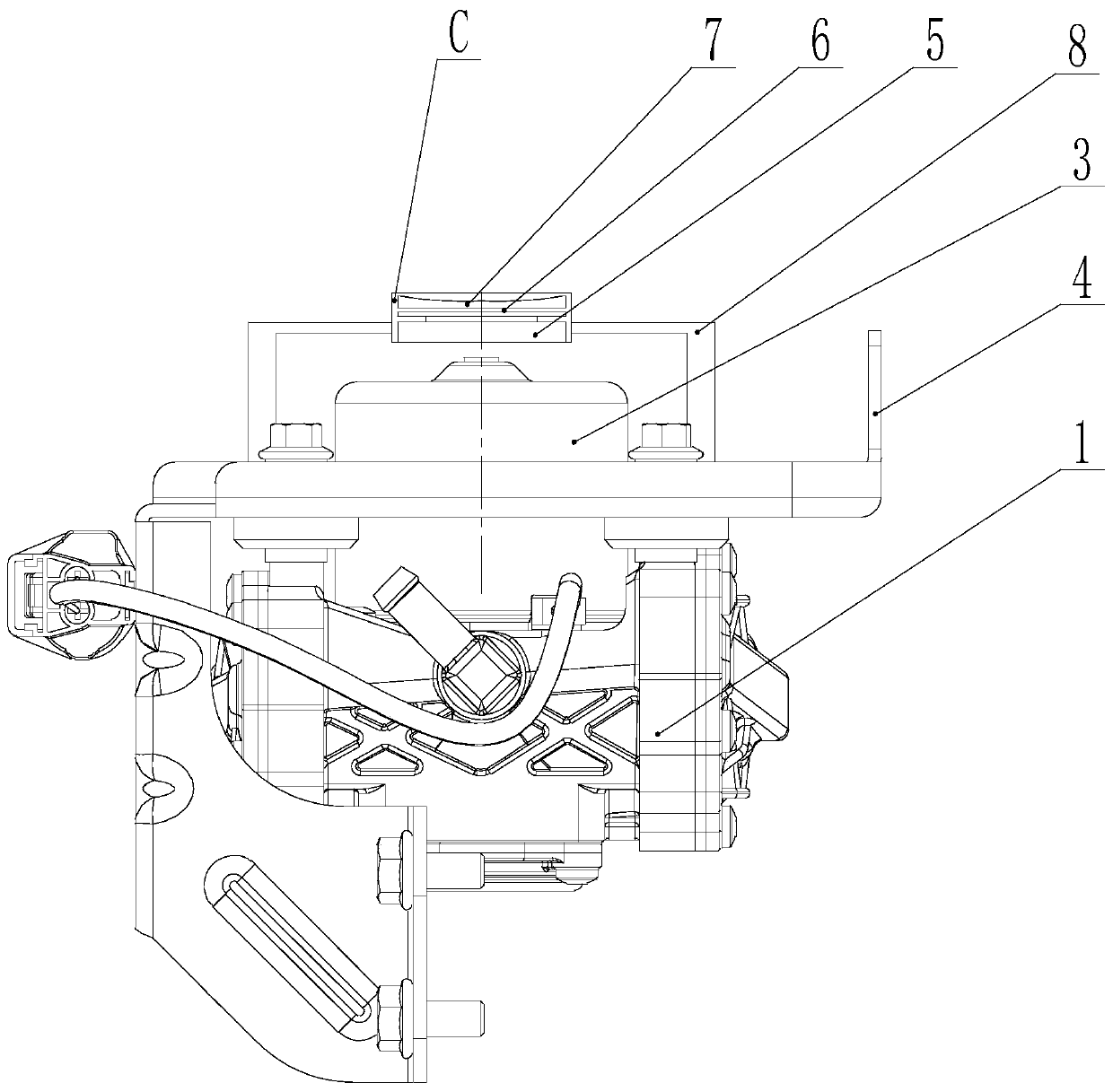

[0018] The device includes a vacuum pump 1 and a noise reducer, wherein the noise reducer includes an acquisition module A, an analysis module B and a playback module C connected by signals. The vacuum pump, analysis module and playback module are all fixed in the engine room, while the acquisition module is fixed in the cockpit. Among them, the acquisition module uses the SIEMENS Test.lab test analysis system, G.R.A.S microphone and accessories; the analysis module is a single-chip microcomputer fixed in the cabin, and the single-chip microcomputer has built-in GOLD WAVE software, which can perform "phase inversion" on the sound collected by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com